Global Zero-Waste Food Tray Microalgae PHA Market :

The global push toward circular packaging systems is accelerating, and few segments exemplify this transformation better than the zero-waste food tray market based on microalgae-derived polyhydroxyalkanoates (PHA). By 2036, this market—once considered experimental—is poised to become a commercially significant segment of the sustainable packaging ecosystem, driven by regulatory pressure, technological breakthroughs, and increased investment.

Market Size and Growth Trajectory

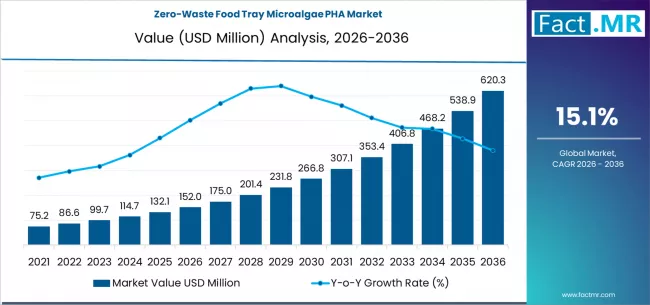

The global zero-waste food tray microalgae PHA market is projected to expand from around USD 175 million in 2026 to over USD 700 million by 2036, achieving a compound annual growth rate (CAGR) exceeding 15%. This growth outpaces conventional bioplastics and aligns with the broader zero-waste packaging market, which is also experiencing rapid expansion due to increasing awareness of environmental impact and legislative bans on single-use plastics.

Food trays and plates are expected to account for nearly two-thirds of total demand within the microalgae PHA segment. Key end-use sectors include quick-service restaurants, airline catering, institutional food services, and ready-to-eat meal producers. Asia, led by China, is emerging as the fastest-growing regional market, fueled by large-scale manufacturing capabilities, aggressive single-use plastic bans, and national bioeconomy initiatives.

Technology Shifts: From Fermentation to Algae-First Platforms

The market’s growth is underpinned by a critical technological shift. Conventional PHA production relies on bacterial fermentation using sugar- or oil-based feedstocks. While effective, these feedstocks compete with food production and remain cost-sensitive. Microalgae-based PHA production represents a transformative approach, using photosynthetic organisms that consume carbon dioxide, grow on non-arable land, and utilize wastewater or saline water.

Advances in strain engineering, photobioreactor design, and downstream extraction have significantly improved yields while lowering production costs. These improvements, coupled with scalability, are positioning algae-based PHA as a viable alternative for high-volume food tray manufacturing. Compared to molded fiber or PLA alternatives, microalgae PHA offers superior heat resistance, moisture and grease barriers, and full biodegradability in industrial and marine environments, making it particularly suitable for zero-waste compliance scenarios.

Demand Dynamics: Regulation Meets Consumer Behavior

Demand growth is driven by the convergence of regulatory mandates and evolving consumer expectations. Governments across Europe and parts of Asia are implementing stricter restrictions on single-use plastics, including comprehensive bans and reuse mandates targeting food service packaging. These policies disproportionately impact food trays, creating a strong incentive for businesses to adopt sustainable alternatives.

Consumer preference is also shifting toward compostable and bio-based materials. Eco-conscious consumers increasingly expect multinational food brands to reduce plastic waste, driving institutional adoption. Early adopters include schools, hospitals, airlines, and corporate cafeterias, which value end-of-life simplicity and materials that integrate seamlessly into organic waste streams. Microalgae PHA trays meet these criteria, reducing sorting complexity and contamination risks while supporting corporate sustainability goals.

Competitive and Cost Outlook

Despite strong demand signals, cost remains a key challenge. PHA bioplastics are currently more expensive than conventional fossil-based plastics. However, the cost gap is narrowing as scale economies, co-product valorization, and carbon credit incentives mature. Microalgae cultivation aligns with corporate decarbonization strategies by utilizing CO₂ directly in production, enabling companies to meet Scope 3 emissions reduction targets.

As production scales, microalgae PHA is expected to achieve cost parity with certain traditional plastics by the early 2030s. Companies that demonstrate cost efficiency, regulatory compliance, and reliable supply chains will capture long-term contracts with major global food brands.

Investment Outlook to 2036

From an investment perspective, the zero-waste food tray microalgae PHA market presents a high-growth opportunity. Venture and growth capital are increasingly flowing into enabling technologies such as proprietary microalgae strains, low-energy harvesting methods, and partnerships with large packaging converters. The broader bioplastics market is also expanding rapidly, creating a favorable capital environment for specialized segments like food trays.

By 2036, industry consolidation is likely as major packaging companies acquire or partner with algae-based material innovators. Strategic collaborations will focus on securing feedstock and intellectual property while scaling production for multinational clients. Early movers who can demonstrate high-quality, cost-effective microalgae PHA production will benefit from strong first-mover advantages.

Sustainability and Circular Economy Impact

Microalgae PHA food trays offer tangible sustainability benefits. They are fully biodegradable, reducing landfill and marine pollution, and they can be industrially or home-composted depending on design. The integration of algae cultivation into food packaging production also contributes to carbon sequestration, supporting global decarbonization goals.

The zero-waste design approach ensures that the entire lifecycle of the tray—from raw material to disposal—aligns with circular economy principles. As governments, corporations, and consumers increasingly prioritize sustainable practices, microalgae PHA trays are positioned as a flagship solution for eco-conscious food packaging.

Browse Full Report : https://www.factmr.com/report/zero-waste-food-tray-microalgae-pha-market

Outlook Summary

By 2036, the global zero-waste food tray microalgae PHA market is expected to surpass USD 700 million in value, with a double-digit CAGR driven by regulatory tailwinds, technology improvements, and evolving consumer behavior. The combination of biodegradable, high-performance material, cost reductions through technological innovation, and growing demand from institutional buyers sets the stage for a transformative decade in sustainable food packaging.

Microalgae-derived PHA trays are not only an environmentally responsible choice—they are a strategic asset for companies seeking to future-proof their packaging, align with ESG commitments, and participate in the growing circular economy. As adoption scales, these trays are set to redefine the standard for zero-waste food service solutions worldwide.