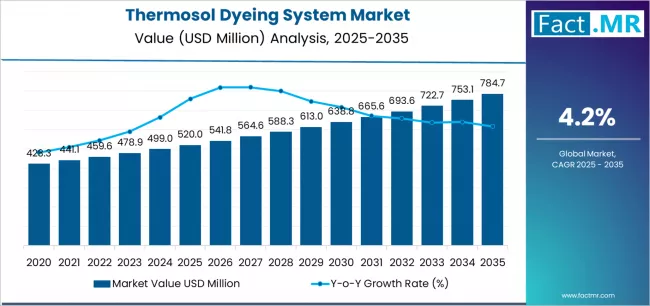

A new market outlook released by Fact.MR projects that the global thermosol dyeing system market will rise from USD 520 million in 2025 to USD 784.7 million by 2035, reflecting a steady CAGR of 4.2%. This growth is strongly driven by textile manufacturers increasing their adoption of continuous and energy-efficient dyeing technologies, amid intensifying environmental regulations and productivity demands.

“With rising global scrutiny on water and chemical consumption in textiles, thermosol dyeing systems have become a strategic and sustainability-focused investment,” said Dr. Neha Singh, Senior Textile Analyst at Fact.MR. “They help mills achieve higher efficiency, faster processing, and reduced environmental footprints—capabilities that are no longer optional but essential in today’s competitive landscape.”

Market Overview

Fact.MR’s newly released insights show that thermosol dyeing systems—once limited to large woven textile operations—are now witnessing broader adoption across apparel, home textiles, and technical textile segments. The market is currently valued at USD 520 million and is projected to reach USD 612.4 million by 2030 before surpassing USD 784.7 million by the end of 2035.

The growth reflects increasing global investment in eco-efficient manufacturing and stronger demand for high-quality dyed polyester, blends, and performance fabrics.

Key Growth Drivers

1. Reduced Water Usage and Environmental Compliance

Thermosol dyeing systems operate with significantly lower water requirements than conventional batch dyeing. As global authorities tighten wastewater discharge norms and environmental standards, textile producers are rapidly shifting toward low-water, low-waste technologies.

2. Energy-Efficient Continuous Processing

These systems allow for quick color fixation without immersion, substantially reducing energy usage and processing time. The continuous nature of thermosol dyeing helps producers minimize labor costs, reduce downtime, and achieve consistent output.

3. Rising Adoption of Polyester and Synthetics

The expanding global consumption of polyester and synthetic fabrics is bolstering demand, as these fibers respond exceptionally well to thermosol dyeing using disperse dyes.

4. Expansion of Technical Textile Manufacturing

Applications in automotive interiors, medical fabrics, industrial nets, and protective wear are growing rapidly, creating new opportunities for precision-oriented continuous dyeing technologies.

Regional Insights

Asia-Pacific Dominates Market Growth

The Asia-Pacific region is expected to remain the growth engine of the thermosol dyeing system market. Textile manufacturing powerhouses such as China, India, Bangladesh, and Vietnam are investing heavily in continuous dyeing lines to meet global export demand and comply with emerging sustainability benchmarks.

Europe & North America Focus on Premium and Niche Applications

Manufacturers in Europe and North America are increasingly adopting thermosol systems for high-end woven textiles, performance fabrics, and sustainable fashion initiatives. These regions benefit from strict environmental frameworks that encourage modernization of dyeing technologies.

Fabric and Dye Segment Trends

Woven Fabrics Retain Majority Share

Woven textiles account for approximately 52% participation in thermosol system installations, with denim, shirting, suiting, and home textiles driving consistent demand. Technical woven fabrics also contribute to steady adoption.

Disperse Dyes Lead with 44% Share

Disperse dyes maintain dominant use in thermosol systems, representing about 44% of the market. Their compatibility with polyester and synthetics supports continued growth. Reactive, vat, sulfur, and indigo dyes also hold notable shares across specific textile applications, particularly in denim and cotton-rich segments.

Medium Line Width Systems Gain Traction

Medium-width thermosol systems (1.9–2.4 meters) are trending as the preferred configuration for textile mills seeking versatility, balanced throughput, and cost efficiency. These systems suit a wide range of fabrics without requiring extensive custom engineering.

Challenges and Opportunities

Challenges

- High Capital Investment: Initial setup costs remain a barrier for smaller units.

- Skilled Labor Needs: Continuous dyeing lines require trained technicians to maintain efficiency.

- System Integration: Aligning thermosol systems with older production layouts can require substantial retrofitting.

Growth Opportunities

- Retrofit Projects: Upgrading batch lines to thermosol creates long-term savings and sustainability advantages.

- Eco-Friendly Textile Expansion: As sustainability becomes mission-critical for global brands, thermosol systems offer manufacturers an opportunity to align with green mandates.

- Technical Textiles: The rise of automotive, medical, and industrial fabrics presents long-term, high-margin opportunities for thermosol technology providers.

- Automation & Digital Monitoring: Emerging automation solutions and IoT integration can help optimize color consistency, reduce downtime, and improve maintenance cycles.

Competitive Landscape

Fact.MR identifies several prominent manufacturers in the global thermosol dyeing system market, including leading European and Asian machinery providers. The market is moderately consolidated, with top companies focusing on:

- Technological innovation

- Energy optimization

- Enhanced reliability

- Reduced environmental footprint

- Integration with industry 4.0 digital tools

Manufacturers are also exploring partnerships with dye chemical companies to develop process-optimized chemistries for superior fabric fastness and performance.

Market Forecast (2025–2035)

From 2025 through 2030, the market is expected to expand by nearly USD 92 million, driven by Asia-Pacific capacity additions and retrofitting activity across Europe. Between 2030 and 2035, a sharper growth curve is anticipated, contributing nearly USD 172 million in additional revenue.

The decade-long outlook highlights consistent capital investment from large composite mills, increasing automation, and growing preference for continuous dyeing systems aligned with sustainability and production efficiency needs.

Executive Commentary

“Textile manufacturers are moving beyond traditional cost-based decision-making,” noted Dr. Neha Singh of Fact.MR. “The new focus is on process consistency, sustainability, and long-term operational efficiency. Thermosol dyeing systems are uniquely positioned to deliver these strategic advantages.”

Browse Full Report : https://www.factmr.com/report/thermosol-dyeing-system-market

About Fact.MR

Fact.MR is a global market research and consulting firm specializing in industrial machinery, manufacturing, and emerging technologies. With a presence in more than 150 countries, the firm delivers actionable insights, forecasts, and strategic guidance to help organizations navigate dynamic market environments.