The global packaging industry is undergoing a fundamental transformation as sustainability becomes a top priority for manufacturers, regulators, and consumers alike. Within this evolving landscape, eco-modulation optimized rigid plastic packaging is emerging as a strategic solution that aligns environmental responsibility with economic efficiency. By linking packaging fees and regulatory incentives to environmental performance, eco-modulation encourages the adoption of recyclable, lightweight, and resource-efficient rigid plastic packaging formats. This approach is reshaping how brands design, produce, and manage plastic packaging across multiple industries.

Market Overview

Eco-modulation optimized rigid plastic packaging refers to rigid plastic packaging solutions that are designed and assessed based on environmental criteria such as recyclability, material efficiency, use of recycled content, and ease of waste management. Under eco-modulation frameworks, packaging that demonstrates improved environmental performance benefits from reduced fees or regulatory advantages, while less sustainable formats face higher compliance costs.

This market is gaining momentum as extended producer responsibility programs expand globally. Governments and regulatory bodies are increasingly pushing packaging producers to take responsibility for the post-consumer lifecycle of their products. As a result, manufacturers are optimizing rigid plastic packaging designs to meet eco-modulation standards while maintaining product protection, shelf life, and branding appeal.

Sustainability and Regulatory Landscape

Regulatory pressure plays a central role in driving the adoption of eco-modulation optimized rigid plastic packaging. Environmental policies focused on plastic waste reduction, circular economy principles, and carbon footprint minimization are accelerating changes in packaging design strategies. Eco-modulation frameworks reward companies that invest in recyclable materials, mono-material structures, and packaging that integrates seamlessly into existing recycling systems.

Beyond compliance, sustainability has become a competitive differentiator. Brands are increasingly transparent about their packaging choices, using eco-optimized rigid plastic solutions to demonstrate environmental stewardship. This shift is particularly evident in consumer-facing industries where packaging sustainability influences purchasing decisions and brand loyalty.

Key Market Trends

One of the most prominent trends in this market is the growing preference for lightweight rigid plastic packaging. By reducing material usage without compromising strength or functionality, manufacturers can lower environmental impact while improving logistics efficiency. Lightweight designs also contribute positively to eco-modulation scoring systems.

Another key trend is the increased use of recycled and bio-based plastics in rigid packaging formats. Incorporating recycled content not only reduces dependence on virgin materials but also enhances recyclability credentials under eco-modulation guidelines. Advances in material science are enabling higher recycled content without sacrificing performance or aesthetics.

Design for recyclability is also gaining traction. Packaging formats that avoid complex multi-layer structures, unnecessary additives, and difficult-to-separate components are favored under eco-modulation systems. This trend is encouraging innovation in packaging engineering, labeling, and closure systems.

Regional Insights

Europe remains at the forefront of eco-modulation optimized rigid plastic packaging adoption, driven by strong regulatory frameworks and advanced recycling infrastructure. The region’s emphasis on circular economy practices has made eco-modulation a critical consideration for packaging producers and brand owners.

North America is witnessing steady progress as sustainability commitments from major corporations and evolving waste management policies drive demand for eco-optimized packaging solutions. Collaboration between packaging manufacturers, recyclers, and policymakers is supporting market growth.

The Asia-Pacific region is emerging as a dynamic market, supported by rapid industrialization, expanding consumer goods sectors, and increasing awareness of plastic waste challenges. Governments and industry players in the region are gradually integrating eco-modulation principles into packaging strategies, creating new opportunities for innovation.

Applications and End-Use Industries

Eco-modulation optimized rigid plastic packaging is widely adopted across food and beverage, personal care, household products, and pharmaceutical industries. In the food sector, rigid plastic containers, trays, and bottles designed for recyclability and material efficiency are increasingly preferred to balance sustainability with product safety.

Personal care and household product manufacturers are leveraging eco-optimized rigid plastic packaging to enhance brand image and meet sustainability targets. Refillable and recyclable rigid packaging formats are gaining popularity as part of broader waste reduction initiatives.

In the pharmaceutical and healthcare sectors, where rigid plastic packaging plays a critical role in product protection and hygiene, eco-modulation optimization focuses on material reduction and improved recyclability without compromising regulatory compliance or safety standards.

Competitive Landscape and Innovation

The competitive landscape of the eco-modulation optimized rigid plastic packaging market is shaped by continuous innovation and strategic partnerships. Packaging manufacturers are investing in research and development to create materials and designs that meet eco-modulation criteria while delivering functional and aesthetic value.

Collaboration across the value chain is becoming increasingly important. Resin suppliers, packaging converters, brand owners, and recycling companies are working together to develop packaging solutions that align with eco-modulation frameworks and circular economy goals.

Future Outlook

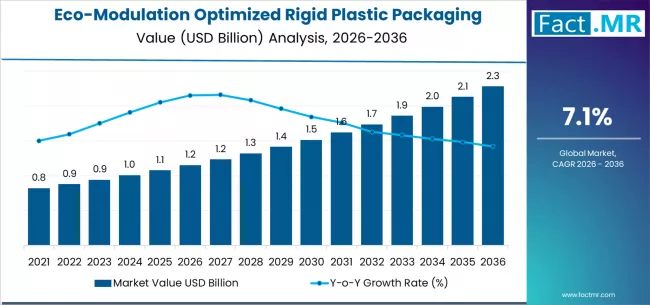

The future of the eco-modulation optimized rigid plastic packaging market looks promising as sustainability expectations continue to rise globally. Eco-modulation is expected to become a standard consideration in packaging design and procurement decisions, influencing material selection, production processes, and end-of-life management.

As regulatory frameworks mature and recycling infrastructure improves, eco-optimized rigid plastic packaging will play a vital role in reducing environmental impact while supporting industrial growth. Companies that proactively adopt eco-modulation principles are likely to gain long-term competitive advantages and strengthen their sustainability credentials.

Conclusion

Eco-modulation optimized rigid plastic packaging represents a critical evolution in sustainable packaging practices. By aligning environmental performance with economic incentives, eco-modulation encourages innovation, accountability, and responsible material use. As industries increasingly embrace circular economy principles, this market will remain central to achieving sustainable packaging goals while meeting the functional demands of modern supply chains.

Browse Full Report – https://www.factmr.com/report/eco-modulation-optimized-rigid-plastic-packaging-market