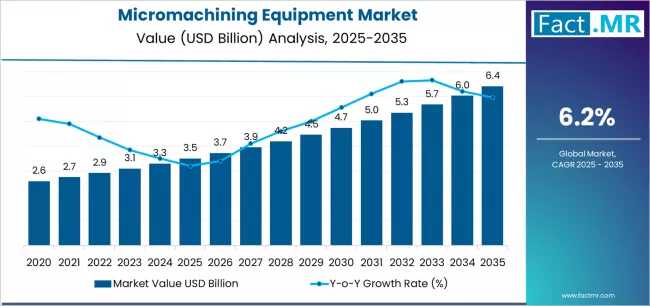

The global micromachining equipment market is on track for substantial expansion, driven by the rapid miniaturization of electronic components, advancements in medical technology, and the growing adoption of precision manufacturing across aerospace, automotive, and photonics industries. Market projections indicate the industry will grow from an estimated USD 3.1–3.5 billion in 2024–2025 to approximately USD 6.2–6.4 billion by 2035, representing a steady CAGR of around 6.2–6.5% over the forecast period.

As manufacturers strive for higher accuracy, improved product functionality, and reduced component size, micromachining has emerged as an indispensable technology. Its ability to create features at micron and sub-micron scale is helping companies achieve previously unattainable levels of precision.

Market Overview

The micromachining equipment market is undergoing a robust transformation characterized by:

-

Accelerated demand for micro-components in electronics and semiconductors

-

Rapid advancements in laser-based micromachining systems

-

Broader adoption of automation and AI-driven quality control

-

Increased investments in medical device miniaturization

-

Rising manufacturing capabilities in Asia-Pacific, especially China and India

In 2024, Asia-Pacific accounted for nearly half of the global revenue, supported by booming semiconductor fabrication, low-cost manufacturing capabilities, and government-backed digital transformation initiatives.

Key Market Drivers

1. Demand for Ultra-Miniaturized Electronics

Consumer electronics, wearables, and sensors continue to shrink in size while requiring greater performance. This trend has led to elevated demand for micromachining technologies capable of producing ultra-small channels, holes, and complex geometries with extreme accuracy. Semiconductor fabrication remains the largest application segment, generating more than one-third of all micromachining equipment demand.

2. Growth of the Medical Device Sector

The medical device industry is experiencing heightened demand for micro-implants, microfluidic devices, diagnostic components, and minimally invasive surgical instruments. Micromachining enables the creation of intricate designs that are impossible to replicate with traditional machining methods. As healthcare continues to shift toward personalized and miniature therapeutics, micromachining will play an increasingly central role.

3. Expansion in Aerospace, Defense, and Photonics

Aerospace and defense industries require precision components that operate under extreme conditions. From turbine blade cooling holes to micro-optical devices and sensors, micromachining enhances durability and efficiency. Photonics, another rapidly growing segment, uses micromachining to create optical waveguides, micro-lenses, and laser components essential for next-generation communication systems.

4. Advancements in Laser and Hybrid Micromachining Technologies

Laser-based micromachining remains the dominant technology, favored for its accuracy, speed, and flexibility. Hybrid systems—combining laser, electrical discharge machining (EDM), chemical etching, or electrochemical machining (ECM)—are gaining popularity due to their ability to handle complex materials and geometries. These innovations also reduce production time and energy consumption.

5. Integration of Automation, Robotics & AI

The adoption of Industry 4.0 principles—AI-driven process optimization, automated quality inspection, and robotic handling—has significantly improved throughput and consistency. Manufacturers increasingly seek micromachining solutions capable of closed-loop monitoring, predictive maintenance, and digital twin integration to maximize operational efficiency.

Market Challenges

While the growth outlook is promising, the industry faces several challenges:

High Initial Capital Requirements

Advanced laser and hybrid micromachining equipment involves substantial investment. Smaller manufacturers may face difficulty adopting the latest high-precision systems due to cost constraints.

Complexity of Precision Manufacturing

Micromachining requires strict control of heat, vibration, and material properties. Managing these tolerances increases production complexity and demands specialized expertise.

Competition from Alternative Technologies

Emerging microfabrication technologies—such as advanced 3D printing and nano-imprinting—are gaining traction. Although micromachining remains superior in precision and material versatility, competing technologies may gradually impact market share.

Competitive Landscape

Prominent manufacturers in the micromachining equipment market include global technology leaders specializing in laser systems, precision machinery, and high-performance industrial fabrication tools. The competitive landscape is characterized by active R&D investment, product line expansions, and collaborations with semiconductor foundries, medical device manufacturers, and aerospace contractors.

Major companies focus on innovation in areas such as:

-

Higher-power ultrafast lasers

-

Real-time beam shaping

-

Multi-axis machining centers

-

Automation and smart software integration

-

Energy-efficient, compact systems

These strategies are enhancing precision, reducing cycle times, and offering end-users increased customization options.

Opportunities for Growth

1. Emerging Markets

India and Southeast Asia offer especially high growth potential due to expanding electronics production, government incentives, and the growing presence of medical device manufacturers.

2. AI-Driven Precision Fabrication

AI can optimize machining parameters, detect defects automatically, and improve repeatability—offering major competitive advantages for equipment providers who integrate smart features.

3. Sustainability & Low-Energy Systems

Green manufacturing is driving demand for energy-efficient micromachining solutions that reduce waste and minimize thermal impact.

4. Co-Development Projects with End-Users

Manufacturers increasingly seek tailored solutions for specific components, opening opportunities for customized system development and long-term service partnerships.

Browse Full Report : https://www.factmr.com/report/micromachining-equipment-market

Executive Commentary

“Micromachining equipment is rapidly becoming the backbone of modern manufacturing,” said [Executive Name, Title]. “From semiconductors to medical implants, precision at the micron level is no longer optional—it is essential for innovation.”

“With digital transformation accelerating globally, the next decade will bring a new wave of smart, automated micromachining solutions that redefine accuracy and efficiency,” added [Expert Name, Title].

About Micromachining

Micromachining refers to the fabrication of small-scale components using laser ablation, micro-milling, EDM, ECM, and hybrid methods. It enables production of parts with dimensions measured in micrometers, supporting industries where ultra-precision and complex geometries are critical.