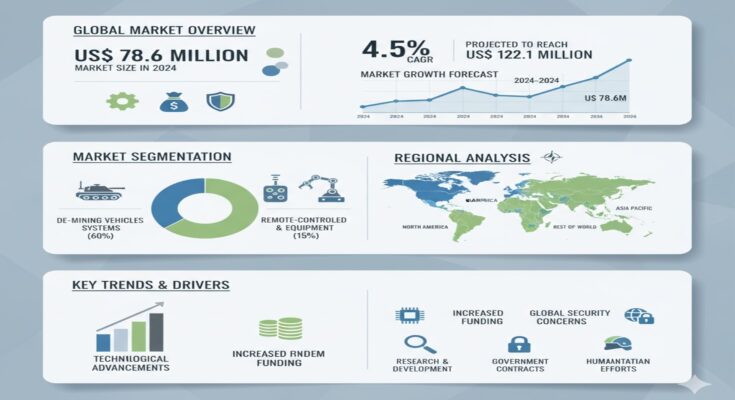

According to a recent report by Fact.MR, the global mechanical mine clearance system market is projected to grow steadily from USD 78.6 million in 2024 to USD 122.1 million by 2034, expanding at a CAGR of 4.5% during the forecast period. The increasing emphasis on post-war recovery, defense modernization, and the integration of autonomous technologies is propelling the demand for mechanical mine clearance systems across the globe.

Strategic Market Drivers:

Humanitarian and Post-Conflict Recovery Efforts

The growing number of landmine-contaminated regions worldwide continues to create an urgent need for effective clearance operations. Mechanical mine clearance systems are playing a crucial role in humanitarian demining initiatives by enabling the rapid restoration of agricultural land, roads, and public infrastructure. Nations emerging from conflict, such as Ukraine, Afghanistan, and parts of Africa, are increasingly adopting mechanized demining technologies to accelerate recovery and resettlement programs.

Enhanced Operational Safety and Efficiency

One of the primary advantages of mechanical mine clearance systems is the reduction of human risk. By allowing remote or armored operation, these systems safeguard personnel from explosive hazards. They are capable of clearing large areas efficiently and are adaptable to different terrains, from rocky landscapes to urban ruins. Advanced systems integrate multiple tools such as flails, tillers, and rollers, enabling flexible deployment depending on the contamination type.

Technological Advancements and Automation

The integration of robotics, artificial intelligence (AI), and remote-control technologies is transforming the mine clearance industry. Modern systems are equipped with real-time monitoring sensors, GPS navigation, and autonomous capabilities, allowing precise, data-driven clearance. Robotic decontamination systems are also being introduced to handle chemical, biological, radiological, and nuclear (CBRN) threats—expanding the application scope beyond traditional explosive clearance.

Defense Modernization and Military Applications

Military forces across the world are investing in next-generation demining systems to secure borders, clear combat zones, and maintain operational mobility. Defense procurement programs in countries such as the United States, the United Kingdom, India, and China are prioritizing mechanical clearance systems as part of broader modernization efforts. These machines not only neutralize landmines but also enable rapid construction of safe passageways for troops and vehicles during military operations.

Regional Growth Highlights:

North America

North America, led by the United States, remains a key contributor to the mechanical mine clearance system market. The region’s demand is supported by ongoing defense research programs, NATO participation in demining initiatives, and technological innovation in autonomous demining systems. U.S.-based defense contractors are also partnering with humanitarian agencies to export mine clearance vehicles to conflict-affected countries.

Europe

Europe holds a significant share of the market, largely due to post-conflict reconstruction projects and strict safety standards for landmine clearance. Nations such as the United Kingdom, Germany, and France are investing in advanced clearance vehicles equipped with flails, robotic arms, and detection sensors. The ongoing war in Eastern Europe, particularly in Ukraine, has amplified demand for high-performance demining systems, with both public and private sectors contributing to supply.

Asia-Pacific

Asia-Pacific is projected to be the fastest-growing regional market. Countries such as China, Japan, and South Korea are investing in smart and autonomous mine clearance solutions. China’s expansion in defense manufacturing and Japan’s focus on robotics and engineering precision are creating favorable conditions for innovation. Additionally, Southeast Asian countries are conducting large-scale clearance programs supported by international aid to rehabilitate war-affected regions.

Middle East, Africa, and Latin America

Emerging economies in these regions are increasingly adopting mechanical mine clearance systems due to rising government-led initiatives, international collaborations, and smart city development programs. The Middle East, in particular, faces significant demand due to conflict-related contamination, while Africa benefits from United Nations and NGO-backed humanitarian demining missions.

Market Segmentation Insights:

By Vehicle Type

- Tracked Mine Clearance Systems: Offer superior stability and are preferred for heavy-duty and military operations.

- Wheeled Systems: Provide flexibility and mobility, especially for humanitarian operations and urban environments.

By Application

- Defense Sector: Dominates the market share due to large-scale procurement by national armed forces.

- Humanitarian Demining: Represents the fastest-growing segment, supported by increased funding from governments and global organizations.

By Technology

- Mechanical Flails and Tillers: Continue to lead due to proven reliability and cost-effectiveness.

- Autonomous and Remote-Controlled Systems: Expected to grow rapidly as automation technologies mature and costs decline.

Challenges and Considerations:

While market growth prospects are strong, several challenges persist:

- High Equipment and Maintenance Costs: Advanced systems require substantial investment, limiting accessibility in developing countries.

- Operational Constraints: Terrain diversity and weather conditions can hinder system efficiency and durability.

- Regulatory and Safety Compliance: Strict safety standards and international protocols must be met before deployment.

- Skill and Training Requirements: Effective system operation demands trained personnel and ongoing maintenance support.

Competitive Landscape:

The mechanical mine clearance system market features a mix of established defense contractors and specialized engineering firms. Leading players include:

Armtrac Limited, Cefa Sas, DOK-ING d.o.o, FAE Group, Hydrema Defence, Pearson Engineering, ScanJack AB, Scopex, Way Industries, and Westminster Group Plc.

These companies are focusing on modular product design, remote control integration, and strategic collaborations to strengthen their market presence. Partnerships with defense ministries, NGOs, and international aid organizations are also helping them expand into new markets.

Recent Developments

- Armtrac Limited (2023): A refurbished Armtrac 400 mine-clearing vehicle was shipped to Ukraine to aid in the removal of landmines left by Russian forces. The Armtrac 400 is designed for versatility, capable of clearing anti-personnel, anti-tank mines, booby traps, and other unexploded ordnance (UXO).

- DOK-ING (2024): The company is developing a robotic decontamination system—the unmanned DOK-ING UGV-M3VAC—for CBRN protection. This system enables decontamination from solid surfaces using a vacuum mechanism, allowing safe operations without human exposure to contaminants or radiation.

Outlook and Future Opportunities:

The mechanical mine clearance system market is entering a new phase of innovation and global collaboration. With technological progress in robotics, AI, and remote sensing, mechanical demining systems are becoming more autonomous, efficient, and adaptable to complex terrains. Governments and humanitarian organizations are expected to increase funding for mine clearance operations, particularly in post-conflict zones and regions with legacy landmine contamination.

As sustainability and safety take precedence, manufacturers like Armtrac, DOK-ING, and Pearson Engineering are expected to lead the market transformation by offering integrated, user-friendly, and environmentally conscious solutions