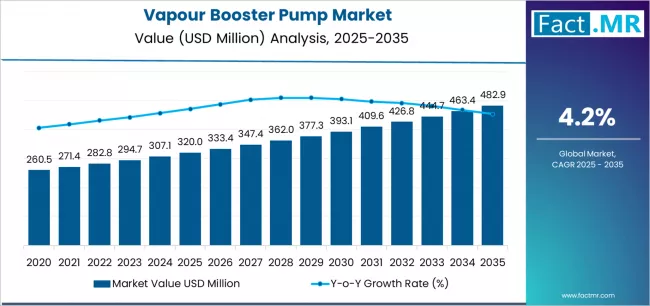

Fact.MR, a leading market intelligence firm, today unveiled its comprehensive Vapour Booster Pump Market Outlook 2025–2035, projecting the global market to grow from USD 320.0 million in 2025 to USD 482.9 million by 2035, at a compound annual growth rate (CAGR) of 4.2% over the decade. This growth is driven by rising industrial demand for oil-free, high-precision vacuum systems in chemical processing, pharmaceuticals, and specialty manufacturing.

“Vapour booster pumps are no longer niche engineering components — they are becoming central to contamination-free, efficient process design in highly regulated industries,” said Dr. Arjun Mehta, Lead Analyst at Fact.MR. “Our analysis shows that manufacturers are increasingly investing in dry-roots booster technologies to deliver both performance and purity, aligning with needs for energy efficiency and tighter emissions control.”

Market Overview

According to the report, the vapour booster pump market is entering a phase of sustained expansion, propelled by advances in vacuum technology and growing industrial reliance on precise vapor handling. The market valuation of USD 320.0 million in 2025 is expected to rise steadily to USD 376.9 million by 2030, and then accelerate to USD 482.9 million by 2035, capturing 65% of its total growth in the 2030–2035 period.

The report underscores that key technology innovation, modular designs, and digital integration are turning vapour booster pumps from specialist tools into indispensable process enablers.

Key Growth Drivers

- Dominance of Dry-Roots Vacuum Boosters

Dry-roots vacuum booster systems are projected to hold the largest technology share, accounting for approximately 42% of the market. Their oil-free mechanisms make them particularly suited for industries requiring ultra-clean vacuum conditions. - Strong Demand in Chemicals & Petrochemicals

The chemicals and petrochemicals sector is forecasted to command the largest end-use share, estimated at 35%. These industries depend on booster pumps for optimizing vapor handling in highly sensitive and contamination-averse processes. - Pharmaceuticals & Precision Manufacturing

The rising demand for highly pure, controlled vacuum environments in pharmaceutical production is boosting adoption. Fact.MR estimates pharmaceuticals will capture around 22% of the market by the end of the forecast period. - Sustainability and Efficiency Pressures

Energy-efficient pumping solutions—paired with reduced maintenance needs—are becoming core priorities for companies managing operational costs and carbon footprints. - Automation & Predictive Maintenance

Integration of IoT-enabled diagnostics and real-time performance monitoring is transforming booster pumps into smart process assets, enabling predictive maintenance and better uptime.

Regional Dynamics

- Asia-Pacific is emerging as the fastest-growing region. Accelerated industrialization, expanding chemical manufacturing capacity, and increasing pharmaceutical production are propelling demand for advanced vapour booster systems across countries such as China and India.

- North America and Europe are expected to maintain steady growth. In these regions, modernizing legacy vacuum systems, stricter environmental regulations, and investments in automation are compelling companies to upgrade to high-performance booster solutions.

- Collaborations between vacuum manufacturers and system integrators are creating region-specific offerings, with digital service models gaining traction among global players.

Technology & Market Trends

- Modular and Low-Maintenance Designs: Manufacturers are increasingly supplying booster pumps with modular architectures, greatly simplifying installation, repairs, and scalability.

- Digital Integration: Real-time diagnostics, IoT-based performance tracking, and predictive maintenance are becoming standard features in next-generation booster systems.

- Energy Optimization: New designs focus on reducing power consumption through better thermodynamic efficiency and advanced control systems.

- Automated Process Compatibility: Vapour booster pumps are being integrated into automated industrial platforms to support continuous, highly controlled processing workflows.

Challenges & Strategic Opportunities

Challenges

- High Initial Investment: Premium booster systems require significant capital, which can be a barrier for smaller or cost-conscious companies.

- Skilled Maintenance Needs: Continuous systems demand trained technicians to maximize reliability and manage sophisticated diagnostics.

- Infrastructure Integration: Retrofitting existing manufacturing lines with advanced booster pump systems may require substantial modification and planning.

- Operating Conditions: In highly corrosive or variable environments, maintaining optimal performance can be difficult.

Opportunities

- Retrofitting Potential: Upgrading legacy vacuum systems to modern boosters offers an effective path to improve purity, reduce waste, and extend equipment life.

- Green Vacuum Solutions: With sustainability mandates tightening worldwide, vapor-boosting technology offers a compelling, environmentally conscious alternative to oil-based vacuum systems.

- Pharma Expansion: The pharmaceutical sector presents a high-value arena for custom booster systems with strict compliance, regulatory, and quality control needs.

- Service-Based Business Models: Vacuum system providers can build new revenue streams through remote monitoring, predictive maintenance services, and aftermarket support.

Competitive Landscape

Fact.MR identifies several key players leading the vapour booster pump market: Edwards Vacuum, Pfeiffer Vacuum, Busch Vacuum, Leybold, and ULVAC. These companies are distinguished by their global presence, deep R&D pipelines, and ability to deliver integrated vacuum solutions.

Market competition is increasingly centered on:

- Enhancing vacuum purity and stability

- Offering low-maintenance, oil-free designs

- Integrating smart monitoring and diagnostics

- Optimizing energy efficiency

Suppliers continue to expand partnerships with system integrators, chemical processing firms, and pharmaceutical manufacturers to deliver tailored booster pump solutions for specialized applications.

Market Forecast Summary (2025–2035)

- 2025–2030: The market value rises from USD 320.0 M to ~USD 376.9 M, driven by growing adoption in chemical and pharmaceutical industries and early digital integration.

- 2030–2035: The market accelerates to USD 482.9 M, led by modular system adoption, IoT-driven optimization, and broader industrial deployment.

- Technology Leadership: Dry-roots vacuum boosters maintain dominance (~42% share).

- Application Focus: Chemicals & petrochemicals (~35%) and pharmaceuticals (~22%) remain key sectors.

Executive Insight

“Over the next decade, vapour booster pumps will evolve from specialized vacuum tools into central components of modern, automated process systems,” said Dr. Arjun Mehta. “Factories seeking higher purity, lower emissions, and smarter operations will depend on these systems—but the real value will come from digital integration and modular flexibility.”

Browse Full Report : https://www.factmr.com/report/vapour-booster-pump-market

About Fact.MR

Fact.MR is a global market research and consulting firm specializing in industrial technology, energy, manufacturing, and advanced machinery markets. Operating in more than 150 countries, Fact.MR equips business leaders with data-driven insights, strategic intelligence, and forecast models to navigate dynamic global markets.