The global pumpable grouts market is entering a high-growth phase, fueled by a worldwide surge in underground infrastructure projects, deep-sea mining, and the urgent rehabilitation of aging civil structures. As urban centers expand and engineering complexities increase, the demand for high-performance, injectable materials has become a cornerstone of modern geotechnical stability.

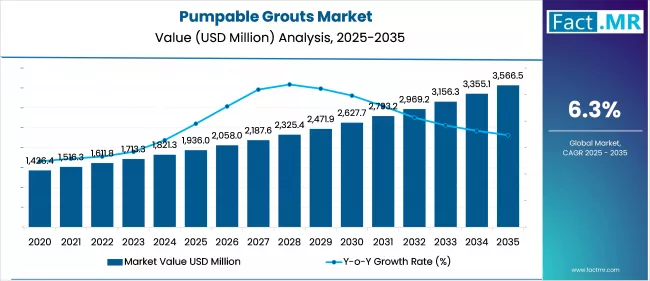

According to recent industry data, the pumpable grouts sector is projected to reach a valuation of USD 3.56 Billion by 2035, growing at a steady compound annual growth rate (CAGR) of 6.1%. This trajectory reflects a significant shift from traditional manual application methods toward automated, high-pressure pumping systems designed to improve structural integrity and reduce labor overhead.

Addressing the “”Who, What, and Why”” of Market Growth

The growth is primarily steered by leading chemical manufacturers and engineering firms, including Sika AG, Mapei S.p.A., and LATICRETE International, who are pivoting toward “”smart”” and sustainable formulations.

- Who: Key stakeholders include civil engineering contractors, mining conglomerates, and government infrastructure departments.

- What: Pumpable grouts—specialized fluid mixtures of cement or resin—are being utilized to fill voids, stabilize soil, and reinforce tunnels.

- When: The surge is immediate, with major project pipelines in Asia-Pacific and North America scheduled through 2030.

- Where: While the Asia-Pacific region holds a dominant 50.3% market share, emerging demand is spiking in the United States (5.4% CAGR) and India, which leads globally with an 8% projected growth rate.

- Why: Rapid urbanization and the “”renewable energy transition”” require stable foundations for everything from high-speed rail tunnels to offshore wind turbine bases.

Key Market Drivers and Technical Evolution

The transition from prescriptive to performance-based specifications is a primary catalyst for innovation. Modern construction requires grouts that offer not just strength, but tailored rheology for long-distance pumping and resistance to extreme environmental loads.

1. Infrastructure and Urban Transit

The rise of metro rail projects and utility tunneling in “”mega-cities”” has positioned cementitious pumpable grouts as the leading segment, currently holding 35% of the market. These materials are essential for backfilling and structural reinforcement in confined urban spaces.

2. Mining and Deep-Earth Operations

As mining operations reach greater depths, the need for water control and void filling becomes critical. Polyurethane and epoxy-based grouts are seeing increased adoption for their rapid-setting properties and ability to halt high-pressure water ingress in hazardous environments.

3. Sustainability and “”Green”” Formulations

Environmental mandates are driving a 15–20% increase in the development of low-VOC and bio-based grouts. Manufacturers are successfully reducing carbon footprints by incorporating recycled aggregates without compromising the 80 MPa+ compressive strengths required for industrial applications.

Regional Insights and Challenges

While the outlook is positive, the market faces headwinds from raw material price volatility and a global shortage of skilled technicians capable of operating advanced pumping machinery.

- Asia-Pacific: Remains the manufacturing and consumption hub, driven by China’s infrastructure spending and India’s residential boom.

- North America & Europe: Growth is concentrated in repair and rehabilitation. With trillions of dollars in aging bridges and dams requiring “”seismic retrofitting,”” specialized repair grouts are becoming a recession-resistant revenue stream.

“”The industry is moving past simple void-filling,”” says one market analyst. “”Today, we are seeing the integration of IoT sensors within grout assemblies to monitor structural health in real-time, marking the era of ‘intelligent’ stabilization.””

Browse Full Report : https://www.factmr.com/report/pumpable-grouts-market

About the Pumpable Grouts Industry

The pumpable grouts market comprises a diverse range of materials—including cementitious, epoxy, and polyurethane systems—designed for high-efficiency placement via mechanical pumping. These solutions are vital for ensuring the longevity and safety of the world’s most critical infrastructure.