The United States float switch sensors industry is poised for robust expansion over the next decade, supported by the rapid evolution of industrial automation, water treatment technologies, and smart monitoring systems.

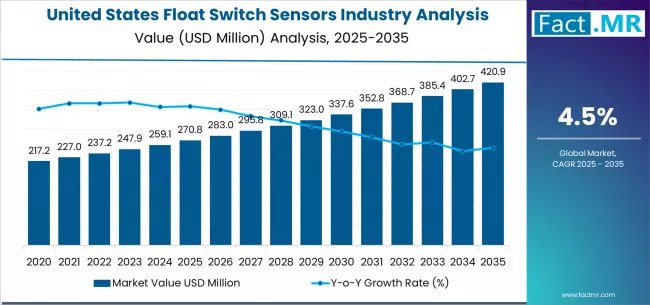

According to a recent report by Fact.MR, the demand for float switch sensors in the U.S. is projected to grow from USD 270.8 million in 2025 to approximately USD 420.9 million by 2035, recording an absolute increase of USD 150.1 million over the forecast period.

This reflects total growth of 49.4%, with demand forecast to expand at a compound annual growth rate (CAGR) of 4.5% between 2025 and 2035.

As industries increasingly rely on precision liquid-level monitoring and control, float switch sensors are gaining traction across manufacturing, wastewater management, energy, food processing, and chemical industries — ensuring efficiency, safety, and compliance in critical operations.

Strategic Market Drivers

Industrial Automation and Smart Manufacturing Growth

Rising automation across U.S. industrial sectors is driving the adoption of advanced level-sensing technologies. Float switch sensors play a key role in fluid management systems, where accurate level detection prevents equipment damage, reduces energy consumption, and optimizes production efficiency.

The expanding integration of Industrial Internet of Things (IIoT) and smart control systems has accelerated the demand for float switch sensors compatible with automated monitoring platforms, enhancing predictive maintenance and operational reliability.

Water and Wastewater Management Expansion

The U.S. government’s continued investments in modernizing water infrastructure and wastewater treatment facilities have significantly boosted demand for reliable level detection systems.

Float switch sensors are increasingly used in pumps, tanks, and treatment systems to monitor fluid levels, detect leaks, and control overflow. The move toward sustainable water resource management is further propelling innovation in durable, corrosion-resistant, and energy-efficient sensor designs.

Growing Adoption in HVAC, Energy, and Food Processing Sectors

In HVAC systems, float switches ensure safety and system efficiency by preventing condensate overflow and compressor damage. In the energy sector, particularly within oil & gas and renewables, these sensors help maintain liquid control in storage, separation, and distribution units.

Meanwhile, in the food and beverage industry, float switch sensors are valued for their hygiene compliance, process consistency, and reliability in challenging environments.

Browse Full Report: https://www.factmr.com/report/united-states-float-switch-sensors-industry-analysis

Regional and Sectoral Highlights

Manufacturing Heartlands Lead Adoption

Manufacturing-dense states such as Texas, Ohio, Michigan, and California are leading adopters of float switch sensors. The focus on automation, coupled with stringent industrial safety standards, drives consistent sensor deployment across production facilities.

Infrastructure Modernization Boosts Demand

Federal and state-level investments under programs like the Infrastructure Investment and Jobs Act (IIJA) are strengthening water treatment networks, fueling adoption of liquid-level monitoring systems in municipal and industrial sectors.

Technological Upgrades and Product Innovation

U.S. manufacturers are increasingly focusing on integrating digital connectivity and AI-based analytics with float sensors to enable real-time performance tracking and anomaly detection. The transition from mechanical to magnetic and electronic float sensors is creating new avenues for precision, reliability, and low-maintenance solutions.

Market Segmentation Insights

By Type

- Magnetic Float Switch Sensors: Widely used due to high accuracy and compatibility with industrial control systems.

- Electronic Float Switch Sensors: Gaining traction for compact design and enhanced reliability in automated applications.

- Cable Float Switch Sensors: Preferred in wastewater management and tank systems for their flexibility and cost-effectiveness.

By Application

- Water and Wastewater Management

- Industrial Automation

- HVAC Systems

- Food & Beverage Processing

- Oil & Gas and Energy Utilities

Challenges and Market Considerations

Despite its promising outlook, the U.S. float switch sensors industry faces challenges such as:

- Supply Chain Fluctuations: Delays in electronic component availability and pricing volatility.

- Competition from Alternative Sensing Technologies: Ultrasonic and radar level sensors offer non-contact advantages in select applications.

- Maintenance Sensitivity: Mechanical float sensors require periodic inspection in high-sediment environments.

Manufacturers are addressing these issues by focusing on advanced materials, robust sealing designs, and digital integration to ensure durability and consistent accuracy.

Competitive Landscape

The U.S. float switch sensors market is characterized by strong competition and continuous innovation. Leading companies are expanding product portfolios, investing in R&D, and forming strategic partnerships to enhance market presence.

Key Players in United States Float Switch Sensors Industry

- Emerson Electric Co.

- Endress+Hauser Group Services AG

- WIKA Group

- Dwyer Instruments, Inc.

- Madison Company, Inc.

- SJE Rhombus

- ATMI, Inc.

- Gems Sensors & Controls, Inc.

- Kobold Messring GmbH

- Magnetrol International, Inc.

Future Outlook: Intelligent Sensing and Sustainable Operations

The future of the U.S. float switch sensors industry lies in smart, sustainable, and connected solutions.

Manufacturers are embracing digital calibration, wireless communication, and eco-efficient materials to meet evolving industrial and environmental standards.

As industries move toward Industry 4.0 ecosystems, the integration of float switch sensors with cloud-based monitoring platforms will redefine fluid control reliability and performance.

With strong demand across critical sectors — from water treatment to advanced manufacturing — the U.S. float switch sensors market is set to remain a cornerstone of America’s industrial automation revolution.