Nowadays, industries generate a lot of waste. Imagine transforming yesterday’s aerospace scrap into tomorrow’s electric vehicles. Suppose this scrap was not discarded but also transformed into a valuable item. We are in dire need of ways where we can reshape industries and drive the global push towards sustainability. Industries face much pressure to reduce waste, conserve resources, and save costs. The titanium scrap recycling market plays a major role in minimizing the environmental impact.

The titanium scrap recycling market is growing rapidly where discarded titanium is used to address the demands of various high-tech sectors. As sustainability is on the rise, recycled titanium is becoming crucial, reducing costs and helping achieve circular economy goals.

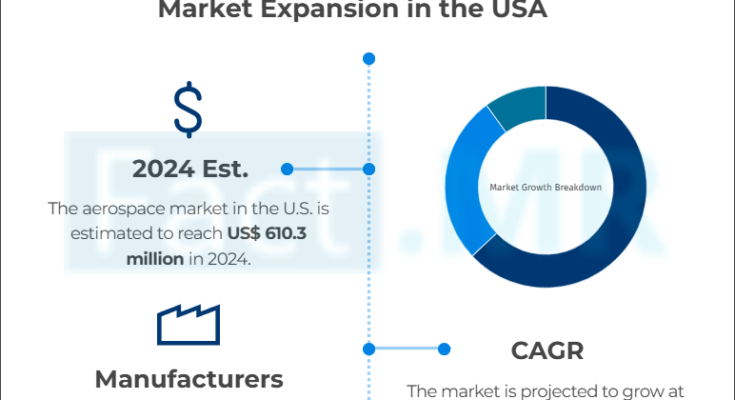

Our comprehensive analysis report estimates US$ 5,512.5 Million valuation by 2034 while United States market is estimated at US$ 610.3 million in 2024.

Recycled Titanium Applications

Recycled titanium plays an important role in addressing the demand for this versatile metal and its good qualities like high strength-to-weight ratio, and corrosion resistance are suitable for diverse industries. Recycled titanium is being used in the following major applications:

- Aerospace Industry – Recycled titanium is extensively used in the production of various aircraft components such as landing gears, airframes, including engine parts. Moreover, its lightweight and durability helps make it an ideal choice for fuel efficiency and performance.

- Medical Sector – In healthcare, it is widely used for various orthopedic devices, dental implants, and surgical instruments. High resistance to body fluids and its high biocompatibility makes it very effective in long-term applications.

- Automotive Industry – Recycled titanium is used mostly in high-performance vehicles for components like suspension parts, and exhaust systems that are lightweight and strength is crucial for efficiency.

- Industrial Applications – Apart from the above-mentioned applications, recycled titanium is used in various chemical processing plants, tanks, and piping systems due to its major qualities like high resistance to corrosion in harsh environments.

Economic Benefits of Titanium Scrap Recycling

- Cost Savings: Recycling titanium helps in reducing costs and recycled titanium is around 60-70% less expensive than virgin titanium. The cost of recycling titanium from scrap is always cheaper than the cost of producing titanium from virgin ones. Mining and refining titanium is a time-consuming process and requires huge capital investment and labor. Recycling titanium offers significant cost reductions for manufacturers in various industries including aerospace, automotive, and medical industries.

- High Scrap Value: Titanium is more expensive than other metals and holds a high market value due to its scarcity and limited availability. Also, the demand for titanium is very high across various industrial sectors like medical, automotive, and aerospace. Titanium recyclers can benefit from the high resale value of titanium and it offers various lucrative opportunities for them. Moreover, scrap yards, manufacturers, and recycling facilities can generate major revenues by collecting, processing, and selling titanium scraps to industries.

- Job Openings: The recycling titanium market is highly labor-intensive and demands skilled professionals to perform the work. Workers collect and sort titanium scrap from industrial waste and aerospace components. Moreover, logistics professionals manage the supply chain and ensure the recycled titanium reaches manufacturers.

Titanium Scrap Market Trends

- Aerospace Industry Driving Demand for Recycled Titanium: Aircraft manufacturers are putting in focus on balancing performance with sustainability. Recycled titanium has become a good choice for components like landing gear, airframes, and engine parts. Moreover, the surge in various factors such as air travel with the rise in defense sector growth is expected to boost the demand. For instance, airspace companies such as Airbus, and Boeing have been using recycled titanium for years in their supply chain. This has been used extensively to reduce costs and meet their environmental targets.

- High Growth of Additive Manufacturing: Nowadays, 3D printing has been used extensively and products are designed and manufactured using additive manufacturing. Titanium particularly in powder form is widely used because of its high strength and biocompatibility. Nowadays, recycled titanium is widely used:

- Medical implants such as dental devices, and orthopedic joints.

- Aerospace components that are effective in reducing weight and fuel consumption.

- Highly effective performance automotive parts that enhance the efficiency of luxury and electric vehicles.

- High Adoption of Electric Vehicles (EVs): Automakers are moving towards electric vehicles and lightweight materials such as titanium are improving vehicle efficiency and battery range. Moreover, recycled titanium is rapidly being used in EV components such as battery enclosures, structural frames, and suspension systems. Market growth for recycled titanium is expected to be high as electric vehicle manufacturers are facing a lot of pressure to meet sustainability goals while maintaining performance. In this case, titanium recycling gives them a strategic advantage.

- Rise in circular economy is expected to boost the adoption of recycled titanium: Across the globe, governments and corporations are adopting circular economy principles to reduce waste and improve resource efficiency. Moreover, titanium recycling is aligned well with these goals to reduce landfill waste, conserve natural resources, and reduce greenhouse gas emissions.

Emerging Markets for Titanium Scrap Recycling

- Asia-Pacific is considered a Hotbed for Growth: Countries such as China, India, and Japan have been expanding their titanium recycling capabilities to support various industrial sectors, such as automotive, construction, and aerospace. High government incentives for sustainable practices and rapid industrialization in this market are expected to contribute to the growth of the titanium recycling market.

- North America is a hub for innovation and leadership: Countries like the US are the hub for innovation due to various leading aerospace and defense companies in the market. Due to the high existence of these companies in the market, titanium recycling innovations are being highly adopted to meet both economic and environmental goals.

- Europe has sustainability at the forefront: Most of the countries in Europe promote sustainability and various factors such as stringent environmental regulations and a strong focus on circular economy initiatives are expected to boost the growth of recycled titanium. Most countries like Germany, France, and the UK have been setting various industry standards for sustainable material usage.

Analyse using a sample of our comprehensive report

Challenges in Titanium Scrap Processing

- Many times, titanium scrap gets mixed with other metals and non-metallic impurities. Various impurities such as aluminum, vanadium, or iron are mixed up during their lifecycle. This contamination further complicates the recycling process and also requires one to use various techniques such as advanced sorting and refining techniques to ensure that high-purity products have been used for reuse.

- Setting up a recycling facility requires good investments. This involves high capital investment and this usually acts as a barrier to entry in the market. Investments are required for specialized equipment, advanced technologies, and, robust infrastructure that is used to handle the unique properties and challenges associated with the entire process.

- Scarcity of titanium can lead to a lot of significant challenges in the market. Unlike various common metals such as steel or aluminum, titanium is rare due to its specialized applications and limited production. Moreover, products that are made from titanium also have longer lifespans and hence these products enter into the recycling stream very late. Other factors such as a fragmented supply chain add to it and as very small quantities of scraps are generated across diverse sectors, this makes the entire process very costly and inefficient. These reasons lead to various factors such as price volatility among manufacturers and recyclers. Moreover, this instability leads to a restriction in planning and raises overall production costs.

- Lack of industry standards mainly the absence of standardized processes and quality benchmarks for recycled titanium can also lead to variabilities and also make it difficult for manufacturers to rely on recycled materials.

Future Ahead

The titanium recycling market has been offering various opportunities to reshape how one thinks about sustainability and innovation. Moreover, titanium has various exceptional properties that are useful in medical, aerospace, and industrial applications. However, some factors restrict the growth, for example, price volatility and scarcity. However, building a more efficient recycling ecosystem is a must here and challenges can be turned into opportunities.

The road ahead looks very promising for the titanium scrap recycling market but it requires support from policymakers, innovators, and businesses. As recycling process of titanium helps reduce environmental impact and also minimizes mining and product emissions. This is a win-win step that not only benefits the environment but also helps industries and consumers in the long term.