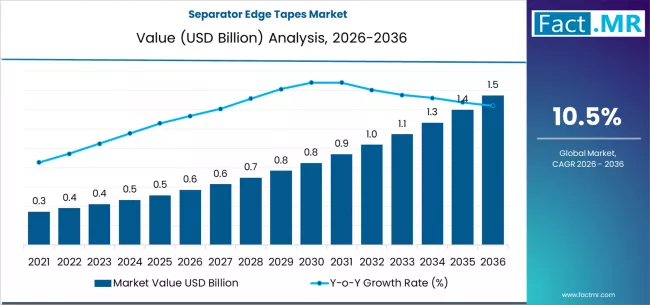

The global separator edge tapes market is poised for steady growth over the next decade, supported by the rapid expansion of lithium-ion battery production, accelerating electric vehicle (EV) adoption, and rising emphasis on battery safety and performance optimization. According to a recent analysis by Fact.MR, the market is expected to grow significantly through 2035, driven by increasing demand from EVs, energy storage systems (ESS), and consumer electronics.

Separator edge tapes play a critical role in lithium-ion battery assembly by reinforcing separator edges, preventing short circuits, improving mechanical stability, and extending battery life. As battery energy density continues to rise, the importance of advanced insulation and edge-protection materials is increasing globally.

Browse Full Report: https://www.factmr.com/report/separator-edge-tapes-market

Strategic Market Drivers

Rapid Growth of Electric Vehicles Fuels Demand

The global transition toward electric mobility is a primary driver of separator edge tape adoption. EV battery packs require enhanced safety, durability, and thermal stability—making separator edge tapes an essential component in modern lithium-ion cells.

Key advantages include:

• Prevention of internal short circuits

• Improved battery cycle life

• Enhanced thermal and mechanical protection

As EV production scales across passenger cars, two-wheelers, and commercial vehicles, demand for high-performance separator edge tapes continues to rise.

Expansion of Lithium-Ion Battery Manufacturing

Massive investments in lithium-ion battery gigafactories across Asia, Europe, and North America are directly supporting market growth. Separator edge tapes are increasingly used in:

• Cylindrical batteries

• Prismatic cells

• Pouch-type lithium-ion batteries

The surge in renewable energy storage systems and grid-scale batteries further boosts demand.

Increasing Focus on Battery Safety and Performance

Battery manufacturers are prioritizing safety compliance and reliability to meet stringent regulatory standards. Separator edge tapes help mitigate risks such as:

• Separator shrinkage

• Electrode misalignment

• Thermal runaway

This makes them indispensable in high-energy-density battery applications.

Advancements in Material Technology

Innovations in polyimide, PET, and advanced adhesive formulations are enhancing tape performance. Improved heat resistance, chemical stability, and adhesion strength are expanding use cases across next-generation batteries.

Regional Growth Highlights

East Asia: Dominant Manufacturing Hub

China, Japan, and South Korea lead global production of lithium-ion batteries, making East Asia the largest market for separator edge tapes. Strong EV supply chains and electronics manufacturing ecosystems drive sustained demand.

Europe: EV Transition and Battery Gigafactories

Europe is witnessing rapid growth due to:

• Aggressive EV adoption targets

• Investments in battery gigafactories

• Strong sustainability regulations

Germany, France, and Nordic countries are key contributors.

North America: Rising Domestic Battery Production

The U.S. and Canada are expanding domestic battery manufacturing capacity to support EV and energy storage demand, accelerating separator edge tape consumption.

Emerging Markets: Long-Term Growth Potential

India, Southeast Asia, and Latin America are emerging as attractive markets due to:

• Growing EV penetration

• Consumer electronics manufacturing

• Renewable energy storage projects

Market Segmentation Insights

By Material Type

- Polyimide (PI) Tapes – High thermal resistance, dominant in EV batteries

• Polyester (PET) Tapes – Cost-effective and widely used

• Others – Specialty polymer-based tapes

By Application

- Electric Vehicles – Fastest-growing segment

• Energy Storage Systems (ESS)

• Consumer Electronics – Smartphones, laptops, wearables

• Industrial Batteries

By Battery Type

- Cylindrical Batteries

• Prismatic Batteries

• Pouch Batteries

Challenges Impacting Market Growth

High Material and Manufacturing Costs

Advanced polymers and precision manufacturing increase overall costs, especially for high-performance applications.

Technical Customization Requirements

Different battery designs require customized tape specifications, adding complexity to production and supply chains.

Supply Chain Dependency

Fluctuations in raw material availability may impact pricing and lead times.

Competitive Landscape

The separator edge tapes market is moderately consolidated, with key players focusing on:

• Advanced material development

• High-temperature resistance

• Strong adhesive performance

• Strategic partnerships with battery manufacturers

Key Companies Profiled

- Nitto Denko Corporation

• Tesa SE

• 3M Company

• Avery Dennison

• Lintec Corporation

• Furukawa Electric

• Saint-Gobain

• Toray Industries

Recent Developments

- 2024: Battery manufacturers increase adoption of high-heat-resistant polyimide edge tapes for next-gen EV cells

• 2023: Expansion of separator tape production capacity in Asia-Pacific

• 2022: Rising use of separator edge tapes in large-scale energy storage systems

Future Outlook: Safety-Driven Battery Innovation

The separator edge tapes market is set to experience sustained growth through 2035, driven by:

• Rapid EV and battery manufacturing expansion

• Increasing energy density and safety requirements

• Growth in renewable energy storage

• Continuous advancements in polymer and adhesive technologies

As lithium-ion batteries become more powerful and compact, separator edge tapes will remain a critical component ensuring performance, reliability, and safety across applications.