Coding and marking systems and solutions have become indispensable in modern manufacturing and packaging processes. They allow companies to print critical product information—such as batch numbers, manufacturing dates, expiry dates, and barcodes—directly on packaging and products. As industries across the globe increasingly prioritize accuracy, traceability, and compliance, coding and marking technologies have emerged as a key operational investment. These systems are integral not only to manufacturing efficiency but also to brand protection and consumer safety.

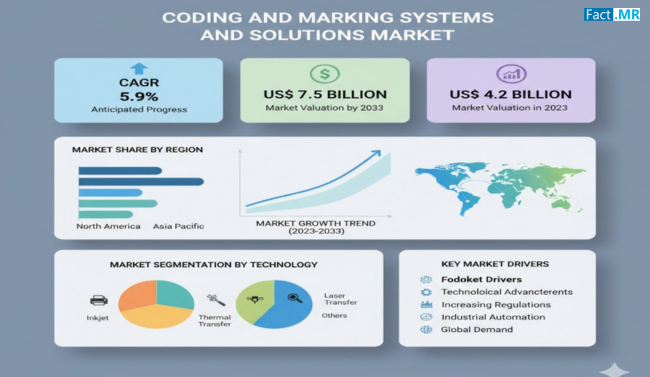

Market Overview:

The coding and marking systems and solutions market covers a broad range of technologies, including continuous inkjet (CIJ), laser coders, thermal inkjet (TIJ), thermal transfer overprinting (TTO), and other specialized marking solutions. Each technology has unique capabilities, enabling manufacturers to choose systems tailored to their operational needs and product types. While laser coders offer high-speed, high-resolution marking suitable for metal and industrial parts, thermal inkjet and continuous inkjet printers excel in flexibility and adaptability across multiple packaging surfaces.

Coding and marking systems are particularly valuable in industries where product information accuracy is essential, such as food and beverages, pharmaceuticals, automotive, electronics, and consumer goods. These solutions not only help companies comply with regulatory requirements but also enhance operational efficiency by reducing errors, facilitating automation, and supporting real-time traceability.

Regional Insights:

Asia-Pacific currently leads the adoption of coding and marking systems, driven by the region’s expansive manufacturing sector and growing demand for packaged consumer goods. Countries like Japan and South Korea are key contributors, leveraging advanced manufacturing practices and digital printing technologies to enhance product identification and traceability.

North America, led by the United States, also represents a mature market, particularly in healthcare and pharmaceuticals, where stringent regulations necessitate reliable coding systems. Meanwhile, Europe is witnessing a steady shift from traditional to digital printing technologies, with countries such as Germany seeing increased adoption of coding systems for automotive and consumer product manufacturing.

Key Trends and Forecast:

Several trends are shaping the coding and marking systems and solutions market:

- Enhanced Anti-Counterfeiting Measures: Manufacturers are increasingly using invisible inks and scannable barcodes to protect products from counterfeiting, particularly in automotive and pharmaceutical industries.

- Adoption of Laser Coders: The demand for laser-based coding systems is rising due to their ability to produce high-resolution markings on diverse surfaces, offering durability and brand protection.

- Environment-Friendly Solutions: Market players are focusing on sustainable and eco-friendly technologies to meet regulatory and consumer expectations, especially in food packaging and healthcare.

- Integration with Digital Manufacturing: Coding systems are being integrated with smart factory operations, enabling real-time monitoring, data collection, and process optimization.

Applications and End-Use Outlook:

Coding and marking systems are widely adopted across industries, each with unique requirements:

- Food & Beverage: Ensuring product safety, compliance, and traceability is paramount, with coding systems helping prevent recalls and maintaining consumer trust.

- Pharmaceuticals and Healthcare: Accurate marking supports regulatory compliance, patient safety, and counterfeit prevention.

- Automotive: Marking vehicle parts with unique codes prevents counterfeiting and supports after-sales tracking and inventory management.

- Electronics and Consumer Goods: Efficient coding ensures proper labeling, batch tracking, and warranty management, enhancing customer satisfaction.

Challenges and Market Restraints:

Despite their advantages, coding and marking systems are not without challenges. High installation and operational costs can be a barrier, particularly for small and medium enterprises. Additionally, integrating advanced coding technologies into existing manufacturing lines may require specialized expertise and training. Manufacturers must balance the benefits of precision and compliance with investment costs and operational complexities.

Conclusion:

The coding and marking systems and solutions market continues to grow, driven by the rising need for product traceability, regulatory compliance, and anti-counterfeiting measures. As technology advances, businesses are increasingly adopting laser, thermal inkjet, and continuous inkjet systems for high-speed, accurate, and durable product marking. These solutions are not only transforming manufacturing and packaging operations but also enhancing brand integrity and consumer trust across industries. Companies investing in robust coding and marking technologies are better positioned to meet evolving industry standards and deliver reliable products to global markets.