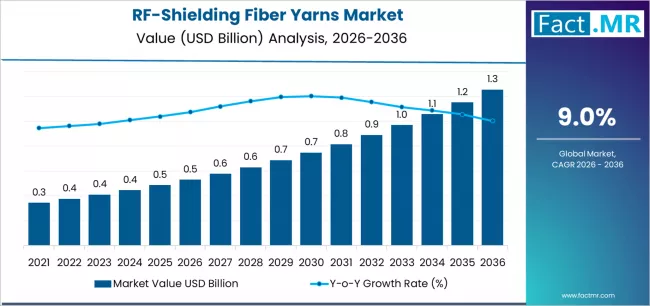

The global RF-shielding fiber yarns market is positioned for strong, sustained growth over the next decade, driven by escalating demand for electromagnetic interference (EMI) protection across electronics, telecommunications, automotive, aerospace, and smart infrastructure applications. According to a recent analysis by Fact.MR, the market is projected to expand from USD 0.53 billion in 2026 to USD 1.25 billion by 2036, registering a robust CAGR of 9.0% during the forecast period.

This expansion represents a total growth of 136.8%, underscoring the critical role of RF-shielding materials in next-generation electronic systems, wearable technologies, and high-frequency communication networks.

The increasing density of electronic components, rising 5G deployment, and stringent EMC compliance standards are significantly accelerating adoption of RF-shielding fiber yarns worldwide.

Browse Full Report: https://www.factmr.com/report/rf-shielding-fiber-yarns-market

Strategic Market Drivers

Surge in EMI & RFI Protection Requirements

Rapid proliferation of electronic devices across industrial, consumer, and defense sectors has intensified the need for effective electromagnetic shielding solutions. RF-shielding fiber yarns offer lightweight, flexible, and durable EMI protection, making them ideal for integration into textiles, cables, enclosures, and composite materials.

Growing concerns over signal integrity, data security, and device reliability are further fueling market expansion.

Growth of Smart Electronics & Wearable Technologies

The rise of wearable electronics, smart textiles, and IoT-enabled devices is significantly boosting demand for RF-shielding fiber yarns. These materials enable seamless EMI protection while maintaining comfort, flexibility, and design adaptability—key requirements in next-generation wearable applications.

Expansion of 5G, Telecommunications & Data Infrastructure

Global deployment of 5G networks, high-frequency communication systems, and data centers is driving demand for advanced RF-shielding solutions. Fiber yarn-based shielding materials provide superior attenuation performance in compact and lightweight designs, supporting high-speed signal transmission environments.

Aerospace, Defense & Automotive Applications

In aerospace and defense sectors, RF-shielding fiber yarns are increasingly used in avionics, radar systems, cable wraps, and protective textiles. Similarly, rising electronic content in electric and autonomous vehicles is accelerating demand for EMI-shielded wiring harnesses and interior components.

Market Segmentation Insights

By Product Type

- Metal-Plated Fibers/Yarns – Dominant segment, accounting for 38.0% of the market in 2026, due to superior conductivity and shielding effectiveness.

- Stainless Steel Fibers

- Carbon-Based Fibers

- Conductive Polymer-Coated Fibers

By Application

- Electronics & Electrical Equipment

- Telecommunications

- Automotive

- Aerospace & Defense

- Medical Devices

- Smart Textiles & Wearables

By End Use

- Industrial

- Commercial

- Military & Defense

- Consumer Electronics

Regional Growth Highlights

North America: Defense & Advanced Electronics Leadership

North America remains a major market due to strong defense spending, advanced electronics manufacturing, and early adoption of EMI compliance standards. The U.S. continues to drive innovation in aerospace, medical devices, and smart textile applications.

Europe: Stringent EMC Regulations Boost Demand

Strict electromagnetic compatibility (EMC) regulations across the EU, coupled with growth in automotive electrification and industrial automation, are accelerating RF-shielding fiber yarn adoption across Germany, France, and the U.K.

East Asia: Electronics Manufacturing Hub

China, Japan, and South Korea dominate production and consumption, supported by robust electronics, semiconductor, and telecom industries. Rapid 5G rollout and smart manufacturing initiatives are key growth catalysts.

Emerging Markets: Infrastructure & Telecom Expansion

India, Southeast Asia, and Latin America are witnessing rising demand due to expanding telecom infrastructure, increasing electronics manufacturing, and growing awareness of EMI protection standards.

Challenges Impacting Market Growth

High Production Costs

Advanced manufacturing processes and the use of conductive metals increase overall material costs, limiting adoption in price-sensitive applications.

Durability & Processing Constraints

Ensuring long-term conductivity, wash durability, and mechanical strength in textile-based shielding solutions remains a technical challenge.

Standardization & Testing Complexity

Meeting diverse global EMC and EMI testing standards increases product development time and compliance costs.

Competitive Landscape

The RF-shielding fiber yarns market is moderately consolidated, with manufacturers focusing on material innovation, enhanced conductivity, lightweight shielding solutions, and integration with smart textiles.

Key Companies Profiled

- Bekaert

- Laird Performance Materials

- Shieldex (Statex Produktions- und Vertriebs GmbH)

- Swift Textile Metalizing

- Toray Industries

- 3M

- Parker Hannifin

- Holland Shielding Systems

Companies are investing in metal-plated yarn innovations, eco-friendly conductive coatings, and high-performance shielding textiles for emerging applications.

Recent Developments

- 2024: Increased adoption of RF-shielding yarns in smart uniforms and military protective gear

- 2023: Expansion of metal-plated fiber production to support 5G and data center demand

- 2022: Integration of RF-shielding yarns in consumer wearables and medical monitoring devices

Future Outlook: A Decade of Advanced EMI Protection Innovation

The RF-shielding fiber yarns market is set to witness transformative growth through 2036, driven by:

- Expansion of 5G and next-gen communication networks

- Rising adoption of smart textiles and wearable electronics

- Growth in EVs, autonomous systems, and aerospace electronics

- Increasing global focus on EMI compliance and signal integrity

- Advancements in lightweight, flexible, and sustainable shielding materials

As industries increasingly prioritize electromagnetic safety, performance reliability, and compact design, RF-shielding fiber yarns will remain a critical enabler of future electronic and textile innovations.