Reciprocating compressors remain a cornerstone of industrial operations, providing reliable, high-pressure air and gas compression across multiple sectors. Known for their durability and performance under demanding conditions, these compressors are essential to industries such as oil and gas, power generation, chemicals, and manufacturing. As industrial modernization and energy efficiency gain momentum, the reciprocating compressor market continues to evolve, driven by technological innovations and increasing demand for robust mechanical solutions.

Market Overview

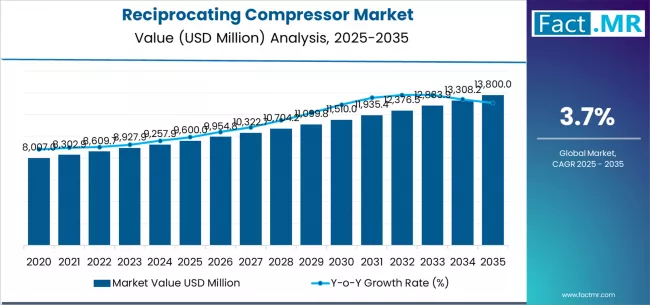

The reciprocating compressor market is witnessing consistent growth as industries focus on optimizing process efficiency and minimizing downtime. These compressors, which function through a piston-driven mechanism to compress air or gas, are valued for their ability to handle variable pressure levels and operate in extreme environments.

Unlike rotary or centrifugal compressors, reciprocating compressors are preferred in applications requiring high pressure, intermittent duty cycles, or customized gas handling. They are commonly deployed in refineries, natural gas pipelines, refrigeration units, and process plants where reliability and precision are paramount.

Ongoing advancements in compressor design — including digital monitoring systems, oil-free configurations, and vibration control — are redefining performance standards. Additionally, sustainability goals are pushing manufacturers to develop eco-friendly models with reduced emissions and enhanced energy efficiency.

Regional Insights

The global landscape for reciprocating compressors reflects a mix of mature and emerging markets, each shaping the demand trajectory differently:

- North America continues to lead due to its strong oil and gas infrastructure and increased investments in shale gas exploration. The region’s focus on maintenance and replacement of aging compressor units also contributes significantly to market growth.

- Europe follows closely, driven by strict emission regulations and ongoing upgrades in chemical and manufacturing facilities. The demand for low-emission, high-efficiency compressors aligns with the region’s sustainability initiatives.

- Asia Pacific is emerging as the fastest-growing regional market. Rapid industrialization, expansion of natural gas networks, and rising manufacturing activities in countries such as China, India, and South Korea are fueling demand.

- Middle East & Africa benefit from extensive oil and gas exploration activities, where reciprocating compressors are essential for gas re-injection and storage.

This geographical diversification ensures that the market maintains resilience against localized economic fluctuations.

Key Trends & Forecast

Several transformative trends are shaping the reciprocating compressor industry:

- Digital Integration and Smart Monitoring: With the rise of Industry 4.0, intelligent compressor monitoring systems are gaining adoption. These systems collect real-time data on temperature, vibration, and pressure, enabling predictive maintenance and minimizing unplanned downtime.

- Energy-Efficient Designs: Manufacturers are focusing on optimizing energy consumption through improved valve designs, advanced materials, and low-friction components. Variable-speed drives are also becoming standard in modern compressor systems.

- Expansion in Natural Gas Applications: The global shift toward cleaner fuels has bolstered demand for gas compression technologies. Reciprocating compressors are widely used for gas storage, transmission, and processing — making them vital for the growing LNG and CNG sectors.

- Oil-Free and Environmentally Friendly Models: To meet environmental regulations and sustainability goals, oil-free reciprocating compressors are gaining traction in food processing, pharmaceuticals, and electronics industries.

- Aftermarket and Service Expansion: As end users prioritize uptime and performance, OEMs and service providers are expanding their aftermarket offerings, including on-site maintenance, retrofitting, and remote diagnostics.

These developments indicate a clear market transition toward smarter, greener, and more adaptable compressor systems.

Applications & End-Use Outlook

Reciprocating compressors serve as critical components across a broad range of industries:

- Oil & Gas: Used extensively in exploration, refining, and gas transport operations. They provide high-pressure compression for gas re-injection, natural gas storage, and process air systems.

- Chemical and Petrochemical: Support critical processes involving hydrogen, nitrogen, and other industrial gases where purity and pressure control are essential.

- Manufacturing & Industrial: Facilitate pneumatic tools, material handling systems, and production line operations that require consistent air supply.

- Power Generation: Integral to turbine control systems and air separation processes, enhancing efficiency and operational stability.

- Refrigeration & HVAC: Used in cold storage, air conditioning, and large-scale cooling systems, especially in sectors with temperature-sensitive operations.

The adaptability of reciprocating compressors to handle both air and gas applications under diverse operational conditions ensures their continued relevance in modern industrial ecosystems.

Competitive Landscape

The global reciprocating compressor market is characterized by a mix of established engineering giants and specialized manufacturers. Key players focus on strategic collaborations, product innovation, and regional expansion to strengthen their market footprint.

Technological differentiation has become a competitive advantage — with companies investing heavily in R&D to improve compressor reliability, minimize energy use, and enhance performance under extreme operating conditions. Partnerships with digital solution providers and IoT integration are further reshaping the industry, enabling smarter and more efficient compressor management.

Conclusion

The reciprocating compressor market is poised for steady expansion as industries modernize and energy efficiency becomes a strategic priority. With a legacy of reliability and adaptability, these compressors continue to evolve to meet new performance, environmental, and digitalization benchmarks.

Organizations looking to optimize their operations should consider advanced reciprocating compressor technologies as part of their industrial efficiency strategy. As global energy transition accelerates, adopting smart, sustainable, and service-ready compressor systems will be key to achieving long-term productivity and compliance goals.

Browse Full Report – https://www.factmr.com/report/reciprocating-compressor-market