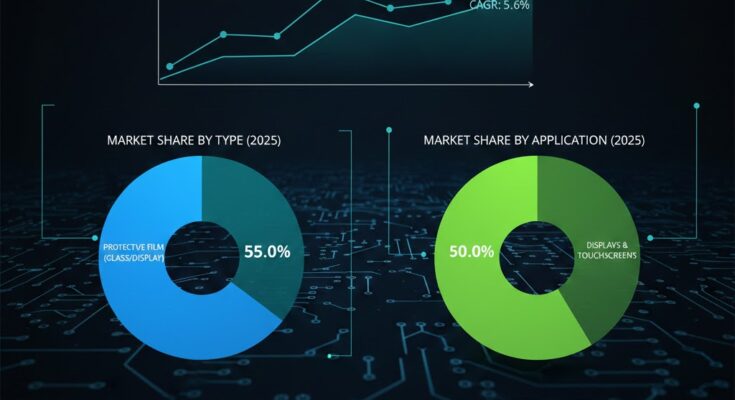

The global pellicle market is set to experience consistent growth through 2035, fueled by accelerating demand from the electronics, semiconductor, and advanced manufacturing sectors. Industry estimates indicate the market is projected to grow from approximately USD 410 million in 2025 to nearly USD 700 million by 2035, expanding at a compound annual growth rate (CAGR) of 5.6% over the forecast period.

Pellicles — ultra-thin protective films used to prevent particle contamination during manufacturing — have become essential components in high-precision environments. Their role is increasingly critical in semiconductor photomask protection, flat panel displays, touchscreens, and optical applications, where even microscopic defects can impact yield and performance.

Electronics and Semiconductor Industries Drive Market Momentum

The rapid expansion of consumer electronics production continues to underpin pellicle market growth. Protective films used in glass and display applications are expected to account for more than 55% of total market revenue, highlighting the sector’s dominance. Displays and touchscreen-based applications alone contribute nearly half of total demand, reflecting widespread adoption across smartphones, tablets, televisions, industrial panels, and automotive displays.

As semiconductor fabrication processes grow more complex, manufacturers are placing greater emphasis on contamination prevention and yield optimization. Pellicles play a vital role in shielding sensitive photomasks from airborne particles during lithography, helping manufacturers maintain production efficiency and reduce costly defects.

Material Innovation Strengthens Competitive Advantage

From a materials perspective, polyester (PET)-based pellicles continue to lead the market, accounting for roughly 60% of overall demand. Their dominance is attributed to a balance of durability, flexibility, optical clarity, and cost efficiency. Additionally, PET-based solutions align well with sustainability goals due to their recyclability and reduced environmental footprint.

Ongoing research and development efforts are focused on improving heat resistance, transparency, and particle-blocking performance, enabling pellicles to meet the evolving technical requirements of next-generation electronics and semiconductor manufacturing.

Asia Pacific Emerges as a Strategic Growth Hub

Geographically, Asia Pacific remains the fastest-growing region in the global pellicle market, supported by strong electronics manufacturing activity and continuous investment in industrial infrastructure. Countries such as China, Taiwan, Singapore, and South Korea are witnessing rising adoption as manufacturers expand capacity to meet global demand for semiconductors and display technologies.

North America and Europe also maintain steady growth trajectories, driven by innovation-focused manufacturing, advanced research facilities, and growing demand for high-performance electronic components.

Competitive Landscape Defined by Innovation and Scale

The pellicle market features a mix of multinational corporations and specialized material manufacturers competing on performance, reliability, and customization. Leading players are investing heavily in product development to deliver pellicles with enhanced contamination resistance, improved lifespan, and compatibility with advanced manufacturing equipment.

Strategic partnerships with semiconductor fabs and electronics manufacturers are becoming increasingly common, allowing suppliers to deliver application-specific solutions while strengthening long-term customer relationships.

Key Market Drivers Supporting Long-Term Growth

Several structural factors continue to support pellicle market expansion:

-

Rising Electronics Consumption: Global demand for smartphones, displays, and connected devices continues to grow.

-

Advancing Semiconductor Nodes: Smaller, more complex chip architectures require superior contamination control.

-

Industrial Automation and Quality Control: Manufacturers are adopting standardized solutions to improve consistency and reduce defects.

-

Focus on Yield Optimization: Pellicles help minimize production losses and downtime in high-value manufacturing environments.

Together, these drivers reinforce pellicles as a critical component in modern manufacturing ecosystems.

Challenges and Market Outlook

Despite its positive outlook, the pellicle market faces challenges, including raw material price volatility, regulatory compliance requirements, and competition from alternative protective technologies. However, continuous innovation and growing emphasis on process efficiency are expected to mitigate these risks.

Looking ahead, opportunities are anticipated in advanced semiconductor lithography, high-definition display technologies, and environmentally conscious material solutions. Manufacturers that align performance innovation with sustainability and customer-specific requirements are expected to gain a competitive edge.

Browse Full Report : https://www.factmr.com/report/pellicle-market

Conclusion

With steady demand from electronics and semiconductor industries, expanding manufacturing capacity in Asia Pacific, and ongoing material advancements, the global pellicle market is positioned for sustained growth through 2035. As precision manufacturing becomes increasingly critical, pellicles will remain a foundational element in ensuring quality, efficiency, and reliability across high-value production