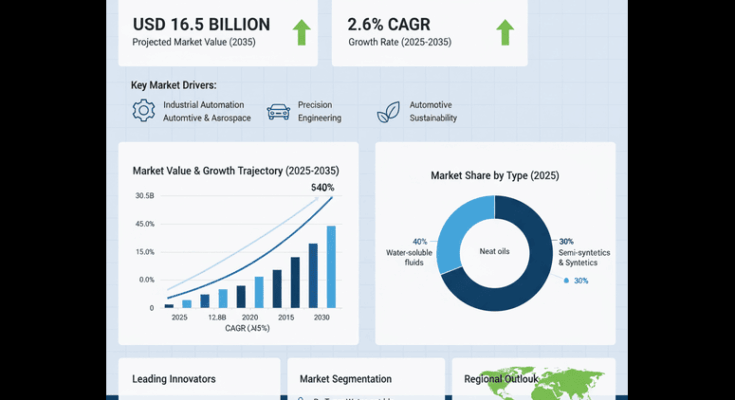

The global metalworking fluid market is on track for steady expansion, with market value projected to rise from USD 12.8 billion in 2025 to USD 16.5 billion by 2035, reflecting a compound annual growth rate (CAGR) of 2.6%, according to Fact.MR. The growth is primarily fueled by industrial automation, advancements in precision engineering, and rising demand across automotive and aerospace manufacturing.

The Role of Metalworking Fluids in Modern Manufacturing

Metalworking fluids (MWFs) play an essential role in machining, cutting, and forming processes across industries. These fluids are designed to cool and lubricate workpieces, extend tool life, improve surface finishes, and enhance process efficiency. As global manufacturing activity rebounds, the need for advanced fluids that can meet performance, safety, and sustainability standards is increasing.

The market’s gradual yet consistent growth reflects the steady pace of industrial development and the modernization of production facilities worldwide. With manufacturers aiming to improve operational efficiency, reduce downtime, and achieve better energy utilization, high-performance and eco-friendly fluids are becoming indispensable.

Segmentation Overview

The Fact.MR report provides a detailed segmentation that highlights the industry’s structure and key demand dynamics:

-

By Type:

-

Water-soluble fluids lead the market due to their superior cooling properties and growing adoption in high-speed machining.

-

Neat oils maintain strong demand in heavy-duty applications requiring maximum lubrication.

-

Semi-synthetics & synthetics are emerging as the fastest-growing segment, driven by innovation in environmentally friendly and long-lasting formulations.

-

-

By Application:

-

Cutting and grinding account for the largest share, reflecting their dominance in machining operations.

-

Forming applications are expanding rapidly, especially in the automotive and aerospace sectors.

-

Protectives and others include fluids designed for rust prevention and surface enhancement, essential in precision manufacturing.

-

-

By End-Use:

-

The automotive sector remains the primary consumer, driven by increased production of electric vehicles (EVs), lightweight components, and high-performance engines.

-

General engineering encompasses industrial machinery, heavy equipment, and energy manufacturing, sustaining consistent demand.

-

Aerospace applications are gaining momentum, emphasizing precision fluids that meet stringent regulatory and performance standards.

-

-

By Region:

-

The Asia Pacific region dominates the market, accounting for a significant share of global consumption, thanks to large-scale manufacturing in China, Japan, India, and South Korea.

-

North America and Europe remain mature markets with strong innovation focus, emphasizing synthetic and bio-based fluids.

-

Latin America and the Middle East & Africa are emerging regions where industrialization and infrastructure growth are stimulating demand for metalworking solutions.

-

Technological Innovation and Sustainability Drive Market Transformation

The metalworking fluid market is undergoing a paradigm shift as manufacturers increasingly adopt smart manufacturing practices and eco-friendly formulations. Traditional fluids, often associated with high waste and environmental impact, are being replaced by sustainable alternatives that reduce toxicity, improve recyclability, and minimize disposal costs.

Water-soluble and semi-synthetic fluids are gaining ground for their efficiency and lower environmental footprint. Additionally, automation and the integration of Industry 4.0 technologies have prompted the need for fluids that can operate efficiently under continuous, high-speed conditions.

Leading companies are focusing on the development of bio-based and hybrid fluid technologies that meet evolving environmental regulations. These innovations help manufacturers comply with sustainability goals without compromising performance — a key differentiator in today’s competitive market.

Competitive Landscape: Leading Market Players

The global metalworking fluid market is moderately consolidated, with several multinational companies dominating global supply and innovation. Major players include:

Quaker Houghton, Fuchs, ExxonMobil, Castrol, TotalEnergies, and Chevron.

These industry leaders continue to strengthen their portfolios through R&D investments, partnerships, and technological upgrades. For example:

-

Quaker Houghton has been expanding its line of high-performance fluids that enhance energy efficiency and reduce environmental impact.

-

Fuchs focuses on customized fluid solutions and digital monitoring systems to improve process control.

-

ExxonMobil and Castrol are investing in next-generation formulations tailored for electric vehicles and precision manufacturing.

-

TotalEnergies and Chevron continue to innovate in the semi-synthetic and water-based segment, targeting improved lubrication and sustainability.

These companies are also leveraging data analytics and predictive maintenance technologies to help industrial customers optimize metalworking processes and reduce downtime.

Emerging Trends and Growth Opportunities

The next decade will bring transformative opportunities for the metalworking fluids industry:

-

Electric Vehicle (EV) Manufacturing:

The EV revolution is changing machining requirements, particularly for battery components, aluminum housings, and lightweight alloys. MWFs tailored for non-ferrous materials will gain traction. -

Aerospace Precision Engineering:

Increasing aircraft production and the demand for ultra-high-precision components are pushing the boundaries of metalworking technology, creating space for specialized fluid formulations. -

Sustainable and Circular Manufacturing:

The push toward carbon neutrality is driving demand for biodegradable and recyclable metalworking fluids, especially in Europe and North America. -

Digital Fluid Management:

Smart monitoring systems that track fluid quality, contamination, and consumption in real time are becoming a key differentiator for industrial users seeking efficiency and compliance.

As industries move toward cleaner, smarter, and more efficient production, the global metalworking fluid market is expected to evolve into a cornerstone of sustainable industrial growth.

Browse Full Report : https://www.factmr.com/report/4543/metalworking-fluids-market