As offshore energy exploration and marine infrastructure projects continue to expand, the demand for environmentally responsible protective solutions is growing steadily. In this evolving landscape, the low-VOC coatings for floating offshore structures market is gaining prominence as industries seek to balance performance, durability, and environmental compliance. These coatings play a vital role in protecting offshore assets while minimizing the release of volatile organic compounds that contribute to air pollution and ecological damage.

With stricter environmental regulations and rising awareness of sustainable marine practices, low-VOC coatings are becoming an essential component of modern offshore construction and maintenance strategies.

Market Overview:

Low-VOC coatings are specially formulated protective materials designed to reduce harmful emissions while delivering long-lasting corrosion resistance in harsh offshore environments. Floating offshore structures—including platforms, vessels, wind turbines, and production units—require advanced coatings to withstand constant exposure to saltwater, humidity, UV radiation, and mechanical stress.

Unlike conventional coatings, low-VOC alternatives use eco-friendly solvents, water-based formulations, or high-solid technologies that significantly reduce environmental impact. These coatings support compliance with global environmental standards while maintaining the structural integrity and operational lifespan of offshore assets.

Regional Insights:

Regions with well-established offshore energy sectors are leading the adoption of low-VOC coatings. North America remains a key market due to its strong offshore oil, gas, and renewable energy infrastructure, along with strict environmental compliance requirements. Europe closely follows, driven by ambitious sustainability goals and increasing investment in offshore wind energy projects.

Meanwhile, Asia-Pacific is emerging as a significant growth region as coastal nations expand offshore exploration and renewable energy initiatives. Growing shipbuilding activity and marine infrastructure development across this region are further supporting demand for environmentally compliant coating solutions.

Key Trends & Forecast:

- Increasing preference for eco-friendly coating systems that meet international emission standards

- Growing adoption of water-based and high-solid coatings for offshore applications

- Rising focus on extending maintenance cycles and reducing lifecycle costs of floating structures

- Integration of advanced coating technologies to enhance resistance against corrosion and biofouling

- Strong collaboration between coating manufacturers and offshore operators to develop customized solutions

These trends reflect a broader industry shift toward sustainable materials without compromising performance or safety.

Applications & End-Use Outlook:

Low-VOC coatings are widely used across various offshore applications, including floating production storage and offloading units, offshore wind turbine foundations, drilling platforms, and marine vessels. These coatings are applied to critical components such as hulls, decks, pipelines, and structural steel to ensure long-term protection against corrosion and environmental wear.

End-use industries such as offshore oil and gas, renewable energy, shipbuilding, and marine engineering are increasingly prioritizing low-VOC coatings to align with sustainability targets and reduce environmental risks. The growing focus on renewable offshore energy installations is particularly accelerating demand for durable, eco-conscious coating solutions.

Technological Advancements and Innovation:

Innovation is a key driver shaping the low-VOC coatings market for floating offshore structures. Manufacturers are investing heavily in research and development to improve coating performance under extreme marine conditions. Advances include enhanced adhesion properties, faster curing times, and improved resistance to abrasion and chemical exposure.

Additionally, the development of smart and self-healing coatings is gaining attention, offering extended protection and reduced maintenance requirements. These innovations not only improve operational efficiency but also help minimize environmental impact by reducing the frequency of recoating and material usage.

Competitive Landscape and Strategic Developments:

The market features a competitive mix of global coating manufacturers and specialized marine coating providers. Companies are focusing on expanding their eco-friendly product portfolios and strengthening their presence in offshore markets through partnerships and technological collaborations.

Strategic initiatives include launching region-specific formulations, obtaining environmental certifications, and offering technical services to support offshore operators in transitioning to low-VOC coating systems. Transparency in product composition and compliance with international marine standards is becoming a key differentiator in the competitive landscape.

Future Outlook:

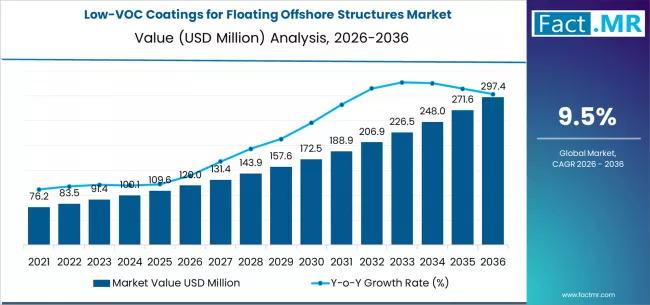

The future of the low-VOC coatings for floating offshore structures market appears promising as sustainability becomes central to offshore development strategies. As environmental regulations tighten and offshore projects grow in scale and complexity, demand for compliant, high-performance coating solutions is expected to rise steadily.

Low-VOC coatings are likely to become the industry standard for offshore applications, driven by their ability to reduce emissions, enhance asset longevity, and support responsible marine operations. Continuous innovation and collaboration across the value chain will further accelerate market adoption.

Conclusion:

Low-VOC coatings for floating offshore structures represent a critical advancement in sustainable marine and offshore engineering. By combining environmental responsibility with robust performance, these coatings enable industries to protect vital offshore assets while meeting evolving regulatory and sustainability expectations. Access to comprehensive market insights can help stakeholders navigate emerging opportunities and make informed decisions in this rapidly evolving offshore coatings landscape.

Browse Full Report – https://www.factmr.com/report/low-voc-coatings-for-floating-offshore-structures-market