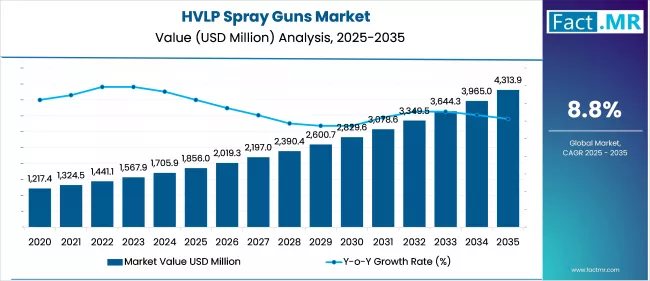

The global HVLP (High Volume Low Pressure) spray guns market is poised for significant expansion over the next decade, driven by increasing demand for high-quality surface finishing, reduced material wastage, and environmentally compliant coating solutions. According to a new analysis by Fact.MR, the market is projected to grow from USD 1,705.9 million in 2024 to USD 4,314 million by 2035, registering a strong CAGR of 8.8% from 2025 to 2035.

This robust growth reflects the rising adoption of HVLP spray guns across automotive refinishing, woodworking, furniture manufacturing, construction, and industrial coating applications, where precision and efficiency are critical.

Browse Full Report: https://www.factmr.com/report/hvlp-spray-guns-market

Strategic Market Drivers

Environmental Regulations Fuel Market Expansion

Stricter global regulations on volatile organic compound (VOC) emissions are pushing manufacturers and end-users toward HVLP spray technology. These systems significantly reduce overspray and material waste, helping companies meet environmental compliance standards while lowering operational costs.

Automotive & Industrial Coating Demand Accelerates Growth

HVLP spray guns are widely used in automotive OEMs and aftermarket refinishing due to their ability to deliver smooth, uniform coatings with superior transfer efficiency. Rising vehicle production, repair activities, and customization trends are accelerating market adoption.

Growth in Construction & Furniture Manufacturing

Rapid urbanization, infrastructure development, and demand for premium interior finishes are boosting HVLP spray gun usage in wood finishing, cabinetry, and architectural coatings. Furniture manufacturers increasingly prefer HVLP systems for consistent quality and reduced paint consumption.

Technological Advancements in Spray Equipment

Manufacturers are introducing lightweight designs, ergonomic handles, digital pressure control, and improved nozzle technology, enhancing operator comfort, precision, and productivity across professional and DIY applications.

Regional Growth Highlights

North America: Automotive Refinishing & DIY Market Strength

North America remains a major market, supported by a strong automotive aftermarket, construction activity, and a growing DIY culture. Regulatory pressure on emissions continues to accelerate the shift toward HVLP spray systems.

Europe: Sustainability-Driven Adoption

European markets benefit from strict environmental regulations, strong furniture manufacturing, and demand for eco-friendly coating technologies. Germany, Italy, France, and the U.K. are key contributors.

East Asia: Manufacturing & Industrial Coating Hub

China, Japan, and South Korea lead regional growth due to their robust industrial manufacturing base, expanding automotive sector, and increasing adoption of efficient spray technologies.

Emerging Markets: Infrastructure & Industrial Expansion

India, Southeast Asia, Latin America, and the Middle East are witnessing growing demand driven by:

- Infrastructure development

- Expansion of furniture and woodworking industries

- Rising industrial coating applications

Market Segmentation Insights

By Product Type

- Gravity Feed HVLP Spray Guns – High precision and reduced paint wastage.

- Suction Feed HVLP Spray Guns – Preferred for larger coating jobs.

- Pressure Feed HVLP Spray Guns – Ideal for continuous industrial applications.

By Application

- Automotive Painting & Refinishing – Largest and fastest-growing segment.

- Furniture & Woodworking

- Construction & Architectural Coatings

- Industrial & Protective Coatings

- DIY & Home Improvement

By End User

- Professional & Industrial Users

- DIY Consumers

Challenges Impacting Market Growth

Higher Initial Equipment Cost

HVLP spray guns typically cost more than conventional spray guns, which may deter adoption among small workshops and price-sensitive users.

Skill & Training Requirements

Achieving optimal results with HVLP systems requires proper training and technique, which can slow adoption among new users.

Competitive Landscape

The HVLP spray guns market is moderately competitive, with players focusing on innovation, ergonomic design, improved transfer efficiency, and regulatory compliance.

Key Companies Profiled

- Graco Inc.

- SATA GmbH & Co. KG

- Anest Iwata Corporation

- Wagner Group

- Devilbiss

- 3M Company

- Campbell Hausfeld

- EXEL Industries

Manufacturers are investing in eco-friendly designs, advanced nozzle systems, and professional-grade spray solutions to strengthen market presence.

Future Outlook: Precision, Efficiency, and Sustainability

The HVLP spray guns market is set for strong long-term growth, supported by:

- Increasing demand for high-quality finishes

- Environmental regulations limiting VOC emissions

- Growth in automotive refinishing and furniture manufacturing

- Technological innovation in spray equipment

- Expansion of DIY and professional coating markets

As industries prioritize precision, sustainability, and cost efficiency, HVLP spray guns are expected to remain a preferred solution for modern coating applications through 2035.