High purity pig iron is a critical raw material in the production of specialty steels and advanced industrial components. Its low impurity content ensures superior mechanical properties, precise chemical composition, and enhanced electromagnetic performance, making it indispensable for automotive, energy, and industrial applications. As industries increasingly focus on high-performance materials, energy efficiency, and electric vehicle adoption, the demand for high purity pig iron is witnessing substantial growth.

Market Overview:

The high purity pig iron market comprises ultra-low impurity feedstock used in producing electrical steels, precision castings, and specialty steel grades. It offers controlled phosphorus and sulfur levels, ensuring consistent quality and superior performance across diverse manufacturing processes. Steel producers, automotive component manufacturers, and electrical equipment fabricators rely on high purity pig iron to meet stringent material specifications and regulatory requirements.

Applications in automotive manufacturing dominate the market, particularly in electric motor cores and transmission components, due to the need for high-performance electrical steels. Energy applications, including transformer cores and renewable energy infrastructure, also drive demand, as high purity pig iron provides superior magnetic properties, reduced energy losses, and predictable processing behavior. The industrial segment, encompassing precision casting and specialty steel production, further expands the market by leveraging the material’s mechanical and electromagnetic advantages.

Regional Insights:

Asia-Pacific is a leading region in high purity pig iron consumption, driven by expanding automotive manufacturing, increasing steel production capacity, and growing renewable energy projects. North America and Europe maintain strong demand, particularly in high-performance automotive components, electrical steel production, and industrial machinery applications. Regional growth is influenced by factors such as industrial output, electric vehicle adoption, regulatory requirements, and infrastructure development for high-quality steel production.

Key Trends & Drivers:

Several factors are shaping the high purity pig iron market:

- Electric Vehicle Adoption:The growing shift from internal combustion engines to electric powertrains increases demand for electrical steels produced from high purity pig iron.

- Energy Efficiency & Sustainability:High purity pig iron enables the production of low-loss electrical steels, improving energy efficiency in motors, generators, and transformers.

- Technological Advancements:Improvements in smelting, iron ore beneficiation, and refining technologies allow manufacturers to maintain ultra-low impurity levels and consistent chemical composition.

- Industrial Expansion:Rising automotive production, specialty steel requirements, and energy infrastructure development drive the adoption of high-grade pig iron.

- Material Innovation:Custom formulations tailored for specific applications, including ultra-low sulfur and phosphorus grades, enhance performance in automotive and energy applications.

Applications & End-Use Outlook:

The automotive and transportation segment represents the largest application area for high purity pig iron. It is extensively used in electric motor cores, transmission components, and specialized automotive steel grades that require precision and high performance. Energy applications, including electrical transformers and renewable energy equipment, benefit from pig iron’s superior electromagnetic properties and predictable processing behavior. Industrial applications, including precision casting and specialty steel production, leverage high purity pig iron for improved mechanical strength, consistency, and quality control.

Technological Developments:

Technological innovations in high purity pig iron production focus on reducing phosphorus and sulfur content, enhancing chemical uniformity, and enabling specialized grades for different industrial applications. Advanced smelting techniques and controlled blast furnace operations allow manufacturers to produce ultra-low impurity iron suitable for high-performance electrical steels. These innovations support the growth of electric vehicles, renewable energy technologies, and specialty steel manufacturing by providing materials with consistent performance characteristics.

Market Opportunities:

The high purity pig iron market presents several growth opportunities:

- Electric Vehicle Expansion:Increasing adoption of EVs creates a strong demand for electrical steels with superior magnetic properties.

- Renewable Energy Infrastructure:Transformers and other energy equipment benefit from low-loss steel products made from high purity pig iron.

- Industrial Diversification:Specialty casting and high-performance steel production require high-grade pig iron with precise chemical composition.

- Sustainable Production:Advances in beneficiation and smelting processes allow manufacturers to reduce carbon footprints while maintaining quality.

- Emerging Market Growth:Developing regions with increasing automotive and steel production offer untapped opportunities for high-quality pig iron supply.

Conclusion:

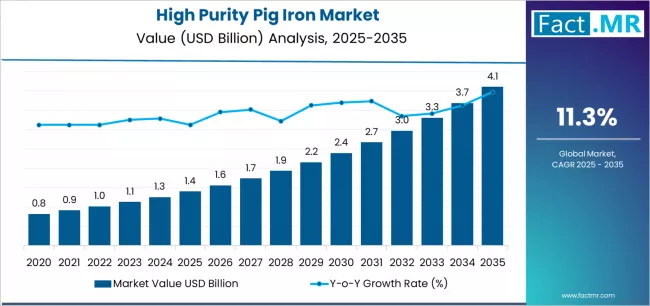

The high purity pig iron market is poised for steady growth as industrial and technological trends favor high-performance, low-impurity feedstock materials. Automotive, energy, and specialty steel applications are driving demand, with electric vehicle adoption and renewable energy infrastructure serving as major growth catalysts. Advanced production techniques, tailored formulations, and regional industrial expansion ensure sustained opportunities for manufacturers and suppliers in this dynamic market. By leveraging high purity pig iron, industries can achieve superior product quality, enhanced energy efficiency, and consistent performance in demanding applications.

Browse Full Report – https://www.factmr.com/report/high-purity-pig-iron-market