The Green Grinding Aids for Cement Mills Market is gaining strong momentum as cement manufacturers worldwide prioritize sustainability, energy efficiency, and reduced environmental impact. Green grinding aids are advanced chemical additives formulated using low-toxicity, biodegradable, or bio-based ingredients that improve cement grinding efficiency while lowering emissions and energy consumption. As the cement industry faces mounting pressure to reduce its carbon footprint, these eco-friendly solutions are becoming an integral part of modern cement production strategies.

Global demand for green grinding aids is expected to rise steadily between 2026 and 2036, supported by increasing cement production, stricter environmental regulations, and a growing emphasis on energy-efficient manufacturing processes. Cement producers are increasingly replacing conventional petroleum-based grinding aids with environmentally responsible alternatives to meet sustainability targets without compromising operational performance.

Key Takeaways from the Green Grinding Aids for Cement Mills Market

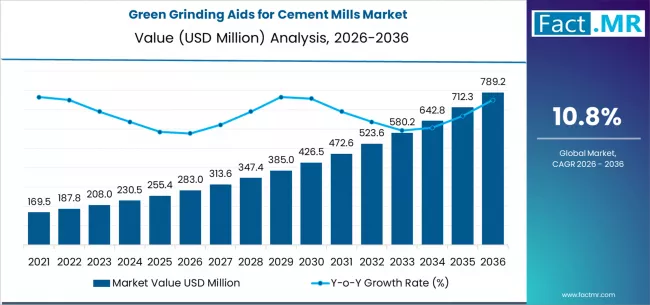

- Market Value for 2026: USD 283.00 Million

- Market Value for 2036: USD 789.19 Million

- Forecast CAGR (2026-2036): 10.8%

- Leading Product Segment Share (2026): Bio-based & biodegradable glycols & esters (28%)

- Leading Functional Benefit Share (2026): Energy reduction & throughput improvement (36%)

- Leading Supply Model Share (2026): Chemical suppliers & formulators (48.0%)

- Key Players in the Market: MBCC Group, BASF SE, Evonik Industries AG, GCP Applied Technologies, Clariant AG, W. R. Grace and Company

To access the complete data tables and in-depth insights, request a Discount On The Report here: https://www.factmr.com/connectus/sample?flag=S&rep_id=13026

Market Growth Drivers

One of the primary drivers of the green grinding aids market is the need to reduce energy consumption in cement mills. Grinding operations account for a substantial share of total electricity use in cement plants. Green grinding aids help reduce particle agglomeration and improve material flow, enabling mills to achieve higher throughput with lower power consumption per ton of cement produced. This directly translates into reduced operating costs and improved profitability.

Environmental regulations are another major growth factor. Governments and regulatory bodies across regions are implementing stricter standards related to emissions, chemical handling, and workplace safety. Green grinding aids, which feature low volatile organic compound (VOC) content and safer chemical profiles, help cement producers comply with these regulations while maintaining high production efficiency.

The growing use of blended and composite cements is also fueling demand. The incorporation of supplementary cementitious materials such as fly ash, slag, and limestone increases grinding complexity. Green grinding aids are specifically formulated to improve grindability and dispersion in such blends, ensuring consistent cement quality and strength development.

Product and Functional Insights

Green grinding aids are available in several formulations, including bio-based glycols, biodegradable esters, low-amine blends, and advanced dispersant systems. Among these, bio-based and biodegradable formulations are witnessing higher adoption due to their favorable environmental profiles and compatibility with sustainability frameworks.

From a functional perspective, energy reduction and throughput enhancement remain the most valued benefits. Additional advantages include improved cement fineness, reduced coating on grinding media, enhanced early strength development, and lower equipment wear. Some green grinding aids also contribute to better handling characteristics and reduced dust formation during milling.

Regional Market Trends

Asia Pacific is expected to dominate the global market due to rapid urbanization, infrastructure development, and large-scale cement production in countries such as China and India. Increasing investments in sustainable construction practices and energy-efficient manufacturing are further strengthening regional demand.

Europe represents a mature yet high-value market, driven by stringent environmental policies and aggressive carbon-reduction commitments. Cement producers across Western and Northern Europe are actively adopting green grinding aids to align with circular economy and decarbonization goals.

North America continues to show steady growth, supported by regulatory compliance requirements and rising awareness of sustainable manufacturing practices. Cement plants in the region are increasingly focusing on optimizing energy usage and minimizing emissions through advanced additive solutions.

Emerging markets in Latin America, the Middle East, and Africa are gradually increasing adoption as cement demand rises and sustainability awareness improves. Infrastructure expansion and modernization of cement plants are creating new growth opportunities for green grinding aid suppliers.

Competitive Landscape

The green grinding aids market is moderately competitive, with chemical manufacturers and specialty additive suppliers focusing on innovation, customized formulations, and technical support services. Companies are investing in research and development to create multifunctional additives that combine energy efficiency, environmental safety, and performance optimization.

Strategic partnerships with cement producers, regional expansion, and tailored solutions for specific raw material compositions are key competitive strategies. Suppliers offering technical assistance, on-site trials, and performance optimization support are gaining a competitive edge.

Challenges and Opportunities

Despite strong growth potential, the market faces challenges related to higher initial costs of green formulations compared to traditional grinding aids. Additionally, performance validation across different mill types and clinker compositions can require extensive testing.

However, long-term cost savings, regulatory compliance benefits, and sustainability advantages continue to outweigh these challenges. As innovation advances and production scales up, pricing is expected to become more competitive, further accelerating adoption.

Future Outlook

The Green Grinding Aids for Cement Mills Market is poised for sustained growth through 2036, driven by the global shift toward sustainable industrial practices. Advancements in bio-based chemistries, increasing regulatory pressure, and the cement industry’s commitment to energy efficiency will continue to shape market expansion. Green grinding aids are expected to become a standard component of cement manufacturing, supporting both environmental goals and operational excellence.

Browse Full Report: https://www.factmr.com/report/green-grinding-aids-for-cement-mills-market