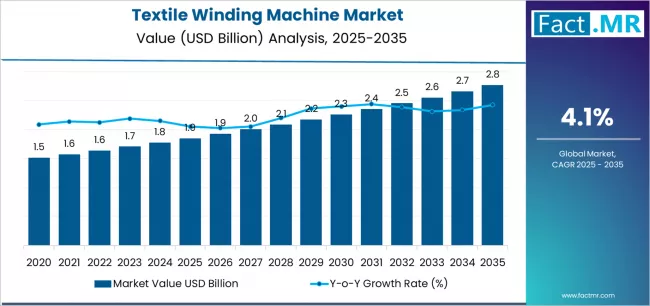

According to a new comprehensive analysis by Fact.MR, the global textile winding machine market is expected to grow robustly over the next several years, rising from approximately USD 2.6 billion in 2024 to USD 4.2 billion by 2031, representing a compound annual growth rate (CAGR) of 6.2%.

This strong forecast reflects accelerating demand for winding machines in key textile-producing regions, driven by the growth of synthetic fibers, technological upgrades in spinning facilities, and expanding apparel manufacturing in Asia-Pacific.

“Winding machines are the unsung heroes of textile manufacturing,” said Dr. Kavita Rao, Lead Analyst at Fact.MR. “Our research reveals that manufacturers across Asia, Europe, and North America are increasingly prioritizing winding automation and high-speed filaments to improve efficiency and reduce waste — and this shift is translating into significant market growth.”

Market Overview

Fact.MR’s report, “Textile Winding Machine Market Outlook 2024–2031,” highlights that the current market valuation of around USD 2.6 billion is supported by strong investments in both traditional yarn production zones and emerging textile hubs. The report documents that rotor winding machines and autoconers remain dominant product types, collectively accounting for more than 45% of market value in 2024.

Modern winding machines with digital controls and automation are seeing rapid uptake, contributing significantly to the projected 6.2% CAGR through 2031. Fact.MR forecasts that automated winding machines will see their share of the total market rise from 30% in 2024 to 45% by 2031.

Growth Drivers

Several major forces are fueling market momentum:

- Rise in synthetic fiber production: Growth in polyesters and other synthetic fibers is catalyzing demand for more sophisticated winding machines that can handle high-speed and high-tension filaments.

- Apparel manufacturing boom: Expansion of global clothing production, especially in Asia-Pacific, is increasing the need for efficient yarn processing and winding.

- Labor efficiency pressures: Textile producers are investing in automated winding solutions to reduce manual labor, cut costs, and improve throughput.

- Sustainability and waste reduction: Fact.MR’s data suggest that modern winding solutions are helping factories reduce yarn waste by up to 12%, enabling more sustainable operations.

Regional Dynamics

Asia-Pacific is expected to remain the most significant regional market, with a projected CAGR of 7.1% during the forecast period. Countries such as India, China, and Bangladesh are leading the charge, driven by low-cost labor, increasing yarn production, and strong export-oriented apparel manufacturing.

In Europe, winding machine investments are more focused on technology upgrades and high-precision automated systems. Fact.MR estimates that Europe’s market share will grow from 22% in 2024 to 26% by 2031, driven by demand for specialty yarns and luxury textiles.

North America is also catching up, with robust demand growth in technical textiles, non-wovens, and performance fabrics. According to the report, automated winding machine sales in North America could grow by 5.8% annually, especially as manufacturers invest in digitization and Industry 4.0-enabled production.

Technology Trends

Fact.MR’s analysis uncovers several critical technology trends reshaping the winding machine industry:

- Industry 4.0 integration: Winding machines equipped with IoT sensors, predictive analytics, and real-time diagnostics are enabling manufacturers to optimize operations, minimize downtime, and avoid yarn breakage.

- Servo-driven systems: These high-precision systems facilitate variable speed control and tension regulation, reducing yarn stress and improving winding quality — a feature that is projected to contribute to 35% of new machine sales by 2028.

- Hybrid winding platforms: Manufacturers are increasingly using machines that can switch between different yarn types (e.g., natural, synthetic, technical) to maximize flexibility in mixed-fiber operations.

Challenges & Opportunities

The report also highlights key challenges that could temper growth:

- High capital expenditure: State-of-the-art winding machines are expensive, and smaller textile players may delay investments due to tight margins.

- Skilled labor shortage: Automation helps, but there is still a need for technical human resources who can manage and maintain advanced winding systems.

- Energy costs: Running high-speed winding lines consumes significant power, particularly in regions where electricity costs are high.

- Supply chain risk: Fluctuations in raw material supply (e.g., specialty electronic components for smart machines) may delay manufacturing and deployment.

Despite these challenges, opportunities abound: retrofitting existing machines, increasing demand for premium yarns, sustainability-driven waste reduction solutions, and rising adoption of digital and smart winding platforms offer promising pathways for growth.

Survey Insights

In addition to quantitative modeling, Fact.MR conducted a survey among 120 textile mill executives across 20 countries to gauge investment sentiment.

- 68% of respondents say they plan to upgrade their winding machines within the next 3 years.

- 72% cited “automation and digitization” as their top priority for new machine purchases.

- 59% said they expect better yarn quality and lower wastage to justify new machine investments.

- 51% indicated that sustainability — reducing yarn loss and power consumption — is a critical factor in capital allocation.

These survey results underscore a clear trend: textile manufacturers are aligning around efficiency, quality, and sustainability goals in their winding machine strategies.

Browse Full Report : https://www.factmr.com/report/textile-winding-machine-market

About Fact.MR

Fact.MR is a leading global market research and consulting firm specializing in industrial, energy, technology, and consumer markets. With a presence across 150+ countries, Fact.MR provides forward-looking insights, data-driven forecasts, and strategic advisory services to help businesses navigate complex market landscapes.