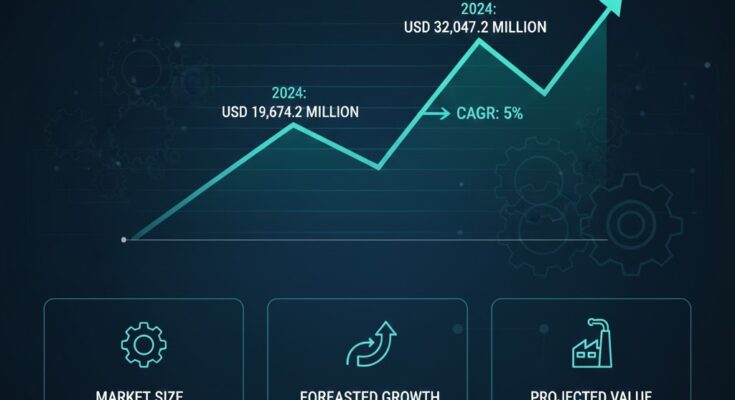

The global Rotating Equipment Repair Market is entering a sustained growth phase as industries worldwide intensify their focus on operational reliability, asset longevity, and cost-efficient maintenance strategies. The market is projected to expand from approximately US$19.7 billion in 2024 to nearly US$32 billion by 2034, registering a compound annual growth rate (CAGR) of around 5% over the forecast period.

Rotating equipment—including pumps, compressors, turbines, motors, and mixers—forms the backbone of industrial operations across energy, chemicals, manufacturing, mining, and power generation. As industrial infrastructure ages and production uptime becomes a critical performance metric, repair and maintenance services are increasingly preferred over full equipment replacement.

Strong Market Fundamentals Drive Long-Term Growth

The steady expansion of the rotating equipment repair market is underpinned by several structural factors. Rapid industrialization across emerging economies, combined with modernization initiatives in mature markets, continues to drive demand for efficient maintenance solutions. Rising electricity consumption, refinery upgrades, and chemical plant expansions are further strengthening the need for reliable rotating machinery performance.

Preventive and predictive maintenance strategies are also gaining prominence as asset owners seek to minimize unplanned downtime and avoid costly production interruptions. Repair services enable operators to extend equipment life cycles while maintaining compliance with safety and operational standards.

Smart Technologies Transform Maintenance Practices

One of the most significant shifts reshaping the market is the integration of digital and smart maintenance technologies. Industrial operators are increasingly deploying condition monitoring systems, IoT-enabled sensors, and data analytics platforms to track equipment health in real time. These technologies allow early detection of performance anomalies, enabling timely repair interventions before failures occur.

The transition from reactive maintenance to data-driven predictive repair models is improving asset reliability, reducing downtime, and lowering long-term maintenance costs—making advanced repair services a strategic priority for industrial facilities.

Regional Outlook: North America Leads, East Asia Accelerates

North America currently represents the largest regional market, accounting for nearly one-third of global revenue. The region benefits from a mature industrial base, significant power generation capacity, and widespread adoption of advanced maintenance technologies. The North American market is projected to grow steadily through 2034, supported by infrastructure upgrades and refinery modernization efforts.

East Asia is emerging as the fastest-growing regional market, driven by rapid industrial expansion and increasing investment in manufacturing efficiency. Countries such as China are prioritizing equipment reliability to support high-volume industrial output, making rotating equipment repair a critical service segment.

Country-Level Highlights

The United States dominates the North American market, accounting for more than half of regional revenue. Demand is fueled by rising energy consumption, expansion of industrial facilities, and a strong focus on predictive maintenance.

In China, large-scale manufacturing operations and continuous industrial upgrades are driving significant demand for rotating equipment repair services. The emphasis on extending equipment life and improving plant efficiency continues to boost market growth across the country.

Segment Insights: OEM Services and Compressor Repairs Lead

From a sales channel perspective, direct OEM-based repair services account for the majority of market revenue. OEMs offer specialized expertise, proprietary components, and end-to-end service capabilities, making them a preferred choice for complex and mission-critical equipment repairs.

By equipment type, centrifugal compressors represent one of the largest and fastest-growing segments. These systems are widely used across energy, chemicals, and industrial gas applications, where performance reliability is essential. Demand for specialized compressor repair and refurbishment services remains strong.

Key Industry Trends

- Life-Extension Solutions: Advanced refurbishment techniques and component retrofitting are enabling operators to delay capital-intensive equipment replacement.

- Sustainability Focus: Efficient repair solutions support sustainability goals by reducing material waste and lowering carbon footprints associated with new equipment manufacturing.

- Service Customization: Repair providers are offering tailored service contracts aligned with specific operational requirements and uptime goals.

Challenges Impacting Market Dynamics

Despite favorable growth prospects, the market faces several challenges. Skilled labor shortages continue to affect service delivery timelines, particularly for highly specialized rotating machinery. Additionally, upfront maintenance costs may discourage smaller operators from adopting comprehensive repair programs. Shifting capital investment toward renewable energy infrastructure may also influence demand patterns in certain traditional industrial segments.

Browse Full Report : https://www.factmr.com/report/rotating-equipment-repair-market

Competitive Landscape

The rotating equipment repair market features a diverse mix of global OEMs and specialized service providers. Leading companies are expanding aftermarket service portfolios, investing in digital diagnostics, and strengthening regional service networks to enhance customer responsiveness. Strategic partnerships and technology-driven service models are becoming key differentiators in a competitive environment.

“