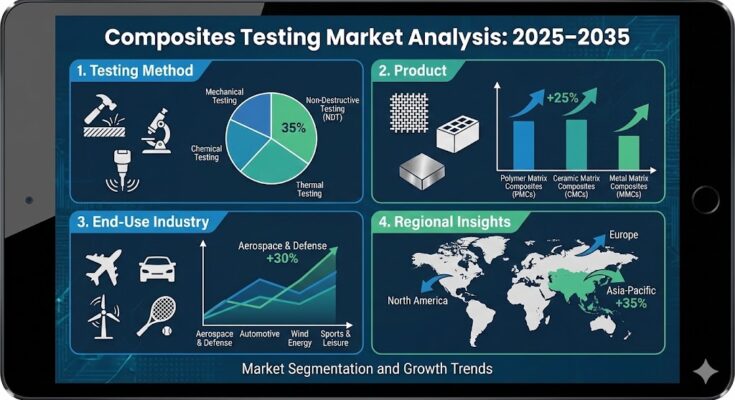

The global composites testing market is valued at USD 2.0 billion in 2025. As per Fact.MR analysis, it will grow at a CAGR of 5.2% and reach USD 3.9 billion by 2035. The industry expanded as demand took the pace in 2024 from the auto and aerospace industries, based on efficiency and safety demands. The growth was fueled by technological advancements such as AI, non-destructive testing, and digital twins that promoted improved test efficiency and precision.

Composites testing, both destructive and non-destructive, ensures materials meet stringent performance and safety standards. Data shows that non-destructive testing (NDT) accounts for 55–60% of total market revenue, with ultrasonic testing capturing 22% of NDT market share, followed by radiography at 18% and thermography at 15%. Destructive testing methods, such as tensile, flexural, and impact testing, comprise the remaining 40–45%, critical for certification and R&D.

Regional Market Insights

-

North America: Dominates the market with 38% global share, supported by aerospace innovation and strict regulatory frameworks. The region invests over USD 1.5 billion annually in composite testing equipment and services.

-

Europe: Holds 35% market share, driven by automotive lightweighting and renewable energy applications. Germany and France alone account for ~60% of Europe’s testing revenue.

-

Asia-Pacific: Forecasted to register the highest CAGR of 9%, due to rapid manufacturing growth in China, Japan, and India. The region’s composites testing market is expected to reach USD 1.8 billion by 2030, nearly doubling from USD 1.0 billion in 2024.

Sector-Specific Data-Driven Demand

-

Aerospace: Composites reduce aircraft weight by up to 20–25%, improving fuel efficiency. Testing ensures compliance with FAA and EASA standards; over 70% of aircraft OEMs invest in in-house composites testing.

-

Automotive: Electric and hybrid vehicles increasingly rely on composites. Testing is projected to grow at 8.2% CAGR in this sector, ensuring crash safety and durability.

-

Construction & Infrastructure: Composites used in bridges and facades show 30–40% higher longevity than traditional materials, driving testing demand.

-

Defense & Marine: Composite materials used in naval and military equipment can withstand temperature ranges from -50°C to 80°C, requiring rigorous validation.

Technological Innovations Driving Market Growth

-

AI-Powered Defect Detection: Detects micro-level defects with up to 95% accuracy, reducing inspection errors by 30%.

-

Automated Ultrasonic Systems: Decrease inspection time by 25–30%, enabling high-throughput testing.

-

Digital Twin Simulations: Allow virtual stress testing, cutting prototyping costs by 15–20% while improving predictive maintenance.

Competitive Landscape and Market Dynamics

Key industry players include MTS Systems Corporation, Instron, ZwickRoell, Element Materials Technology, and Intertek Group, collectively capturing ~45% of the global market. Strategic expansions include:

-

Element Materials Technology: Opened a €20 million composites testing lab in Germany in 2024.

-

Instron: Launched AI-enabled universal testing machines, reducing error rates by 25% and boosting testing speed.

SMEs are also contributing, especially in wind energy and EV components, with niche solutions for fiber-reinforced polymers and thermoplastic composites.

Market Drivers & Challenges (Quantified)

Drivers:

-

Rising adoption of lightweight composites, expected to reach 10 million tons globally by 2030.

-

Increasing aerospace & automotive safety regulations, driving $2.2 billion in testing investments by 2025.

-

Government infrastructure and renewable energy initiatives projected to inject USD 1.5 billion in testing demand by 2030.

Challenges:

-

High capital expenditure for advanced testing equipment ($250K–$1M per system).

-

Global shortage of trained testing professionals, with a 20% skill gap reported in Europe and North America.

-

Lack of standardized protocols in emerging markets, slowing adoption by 10–12% annually.

Browse Full Report : https://www.factmr.com/report/composites-testing-market

Future Outlook

The composites testing market is forecasted to maintain 7–9% CAGR globally, with AI, automation, and digital twin technologies enhancing testing accuracy, reducing operational costs, and enabling faster certification cycles. By 2030, composites testing is expected to be indispensable for aerospace, automotive, defense, and construction applications, ensuring material reliability, safety, and long-term performance.”