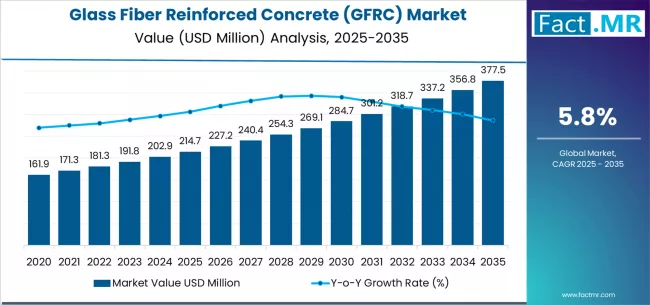

The global glass fiber reinforced concrete (GFRC) market is poised for strong expansion over the next decade, fueled by rising demand for sustainable building materials, advanced architectural facades, and lightweight high-strength composites. According to a recent analysis by Fact.MR, the market is expected to grow from USD 214.7 million in 2025 to USD 377.5 million by 2035, reflecting a CAGR of 5.8% and an absolute increase of USD 162.8 million during the assessment period.

GFRC—known for its superior strength-to-weight ratio, design flexibility, and enhanced durability—is rapidly becoming the material of choice for modern construction projects globally. Its environmentally friendly profile, low maintenance needs, and exceptional structural efficiency are accelerating adoption across architectural, commercial, and infrastructure segments.

Strategic Market Drivers

Sustainable Construction Materials Gain Momentum

With the global construction sector shifting toward low-carbon, eco-conscious materials, GFRC is gaining traction due to its reduced cement content, recyclability, and minimal environmental footprint. Builders and architects increasingly prefer GFRC for cladding, façades, and decorative elements due to its long lifecycle and lower embodied energy compared to traditional concrete.

Urbanization, green building certifications, and tightening environmental regulations further bolster GFRC adoption in both commercial and residential spaces.

Browse Full Report: https://www.factmr.com/report/glass-fiber-reinforced-concrete-gfrc-market

Architectural Innovation Boosts GFRC Demand

GFRC’s unique ability to achieve intricate shapes, thin sections, and complex surface textures is transforming contemporary architecture. Designers are leveraging GFRC for:

- Curved façades

- Ornamental moldings

- Fins and screens

- Decorative panels

- Lightweight structural elements

Its excellent resistance to cracking, weathering, and fire makes it ideal for both exterior and interior applications in modern infrastructure.

Growing Use in High-Performance Infrastructure

Governments and private contractors are increasingly adopting GFRC for infrastructure upgrades—including bridges, metro stations, civic buildings, and public spaces—due to its structural efficiency and reduced maintenance needs.

The material’s superior load-bearing capacity, high tensile strength, and flexibility make it an attractive choice for high-stress applications.

Regional Growth Highlights

North America: Leader in Architectural GFRC Applications

North America remains a prominent market driven by rapid adoption of GFRC in commercial complexes, hospitality projects, and modern building façades. The U.S. leads in design-driven applications supported by advanced manufacturing capabilities and strong construction spending.

Europe: Sustainability Regulations Fuel GFRC Adoption

Europe’s stringent eco-building norms and focus on architectural aesthetics are boosting the use of GFRC in façade renovation, heritage restoration, and green buildings. Countries like Germany, the U.K., and France are investing in energy-efficient and sustainable construction solutions, expanding GFRC penetration.

East Asia: Infrastructure Growth Creates High-Value Opportunities

China, Japan, and South Korea are witnessing significant growth in GFRC usage driven by urban mega-projects, metro expansions, airport infrastructure, and upscale residential developments. Rising investment in durable and design-oriented materials is accelerating regional momentum.

Emerging Markets: Rising Construction Spending Drives Demand

India, Southeast Asia, Middle East, and Latin America offer robust opportunities due to increasing commercial development, rapid urbanization, and the adoption of modern architectural materials. Global manufacturers are expanding their presence in these regions through partnerships and capacity expansion.

Market Segmentation Insights

By Process Type

- Spray-Up GFRC – Dominant due to superior strength and suitability for complex architectural elements

- Premix GFRC – Gaining popularity for smaller components and consistent batch quality

- Hybrid GFRC – Emerging for large-scale projects requiring uniform performance

By Application

- Architectural Panels – Largest segment driven by façade and cladding demand

- Building Façades & Cladding – Fastest growing due to design innovation

- Decorative Elements – Expanding in commercial & hospitality sectors

- Infrastructure Components – Increasing adoption for structural efficiency

By End Use

- Commercial Construction – Offices, malls, hotels

- Residential Buildings – Premium and luxury housing

- Public Infrastructure – Airports, stations, civic structures

- Industrial Sites – Durable exterior components

Challenges Impacting Market Expansion

- High Initial Costs – Advanced production processes and skilled labor increase product pricing

- Installation Complexity – GFRC requires specialized fabrication & installation expertise

- Raw Material Fluctuations – Price instability of glass fibers and cement impacts overall cost

- Competition from Alternative Composites – Fiber-reinforced polymers (FRP) and engineered stone

Competitive Landscape

The GFRC market is moderately consolidated, with companies focusing on technology upgrades, sustainable formulations, and innovation in design capabilities.

Key Companies Profiled

- Willis Construction

- Stromberg Architectural

- Clark Pacific

- Telling Architectural

- Loveld

- Fibrex Construction Group

- Formglas Products

- Nippon Electric Glass Co.

- BarChip Inc.

Manufacturers are investing in improved fiber-cement bonding, eco-friendly admixtures, advanced spraying technologies, and lightweight panel systems that enhance installation efficiency.

Recent Developments

2024:

Launch of ultra-light GFRC panels with enhanced thermal performance for green building applications.

2023:

North American makers expanded their product lines with customizable 3D-molded GFRC for modern architecture.

2022:

European construction firms adopted GFRC with eco-friendly binders and recycled fibers to support sustainable infrastructure.

Future Outlook: A Decade of Sustainable, Design-Driven Growth

The next decade will usher in significant advancements in GFRC manufacturing, including low-carbon composites, automated spraying systems, and digital design integration (BIM-driven panel fabrication). As demand for high-performance, aesthetically versatile, and eco-friendly building materials intensifies, GFRC is expected to play a critical role in next-gen architecture and infrastructure.

With its unique blend of durability, lightweight design, and environmental benefits, the glass fiber reinforced concrete market is positioned for strong, resilient growth through 2035.