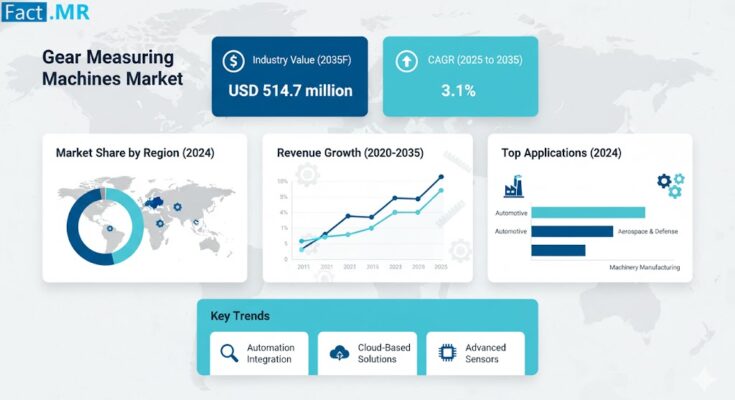

The global gear measuring machines market is poised for steady expansion, driven by the growing need for precision inspection and quality assurance in the automotive, aerospace, and industrial machinery sectors. According to a recent report by Fact.MR, the market is projected to grow from USD 379.3 million in 2025 to USD 514.7 million by 2035, reflecting a CAGR of 3.1% during the forecast period.

As industries continue to adopt automation and digital inspection systems, gear measuring machines have become indispensable tools for ensuring dimensional accuracy, surface integrity, and operational efficiency in gear manufacturing and maintenance.

Strategic Market Drivers

- Rising Demand for High-Precision Gear Inspection

The demand for high-precision gears in automotive drivetrains, robotics, and aerospace applications is pushing manufacturers to invest in advanced metrology systems. Gear measuring machines enable precise analysis of gear geometry—including profile, lead, and pitch—ensuring compliance with stringent quality standards.

With the rapid rise in electric vehicle (EV) production, where noise reduction and efficiency are paramount, precision gear inspection has become a critical aspect of the manufacturing process.

- Integration of Automation and Digitalization

The transition toward Industry 4.0 is transforming the gear measurement landscape. Integration of CNC control, AI-powered analytics, and cloud-based data management enhances process repeatability and reduces human error.

Modern gear measuring systems are now equipped with robotic loaders, touchless optical sensors, and digital twins, enabling real-time inspection and predictive maintenance capabilities—key factors driving operational efficiency in smart factories.

- Growing Adoption in Aerospace and Energy Sectors

Aerospace manufacturers and power generation companies are increasingly relying on gear measuring machines for turbine, transmission, and gearbox component inspection. The machines’ ability to measure complex geometries with sub-micron precision supports performance optimization and longevity of high-value mechanical assemblies.

In renewable energy, the growing number of wind turbine installations is fueling demand for large-scale gear measurement systems, essential for verifying the accuracy of massive gear components used in nacelles and rotor assemblies.

Browse Full Report: https://www.factmr.com/report/2062/gear-measuring-machine-market

Regional Growth Highlights

East Asia: Manufacturing and Automation Hub

East Asia dominates the global gear measuring machine market, led by China, Japan, and South Korea, which host some of the world’s most advanced automotive and industrial equipment manufacturing ecosystems.

Increasing automation in production lines and the presence of key machine tool manufacturers are propelling regional demand. Japan, in particular, continues to lead in metrology innovations and high-precision engineering tools.

Europe: Technological Leadership in Precision Metrology

Europe remains at the forefront of gear measurement technology, with countries like Germany, Switzerland, and Italy serving as innovation centers for metrology and machine tool design. The region’s emphasis on sustainability, energy efficiency, and automation supports adoption of advanced measuring machines across sectors.

North America: Focus on Industrial Modernization

The U.S. and Canada are witnessing robust demand for gear measuring machines, driven by the modernization of aerospace and automotive facilities.

Growing investments in smart manufacturing infrastructure, coupled with strong regulatory standards for precision and safety, continue to stimulate market growth.

Emerging Regions: Industrial Expansion and Localization

South Asia, Latin America, and the Middle East are showing growing potential as regional manufacturing bases expand. Government-led industrialization programs and foreign investments in automotive and heavy engineering sectors are spurring demand for advanced inspection equipment.

Competitive Landscape

The global gear measuring machine market is highly competitive, characterized by technological innovation, product differentiation, and strategic partnerships between manufacturers and industrial end-users.

Key Players in the Market Include:

- Gleason Corporation

- KLINGELNBERG

- KAPP Werkzeugmaschinen GmbH

- Wenzel America Ltd.

- Osaka Seimitsu Kikai Co., Ltd.

- Tokyo Technical Instrument, Inc.

- Gearspect Group A.S.

- Marposs S.p.A.

- Hexagon AB

- ZEISS International

- MDM Metrosoft S.r.l.

- United Gear & Machine Company, Inc.

- Continental Control System

- Mitutoyo Corporation

- Renishaw

- FAG (Schaeffler Group)

- Starrett

- Mahr GmbH

- Komet Group

- Tokyo Seimitsu Co., Ltd.

These companies are focusing on AI-driven precision software, modular inspection systems, and automation integration to enhance measurement speed, accuracy, and versatility. Strategic collaborations and investments in digital metrology platforms are also shaping future market dynamics.

Recent Developments

- April 2023 – Gleason Corporation introduced its latest gear inspection software suite integrating AI-based error detection and cloud analytics to improve process control.

- October 2022 – ZEISS International expanded its industrial metrology portfolio with new optical inspection systems offering ultra-fast 3D scanning capabilities for complex gears.

- May 2022 – Hexagon AB unveiled advanced sensor integration solutions enabling hybrid inspection combining tactile and optical measurements for enhanced accuracy.

Future Outlook: Advancing Toward Intelligent Metrology

The future of the gear measuring machine market lies in smart, connected, and sustainable precision technologies. Integration of AI, IoT, and machine learning will enable predictive maintenance, automated error correction, and closed-loop quality control in real time.

As global manufacturing evolves toward higher precision, efficiency, and digital traceability, gear measuring machines will play a pivotal role in ensuring operational excellence and product reliability.

Manufacturers prioritizing innovation, digital transformation, and eco-efficient systems will lead the next phase of market growth—shaping the future of precision engineering worldwide.