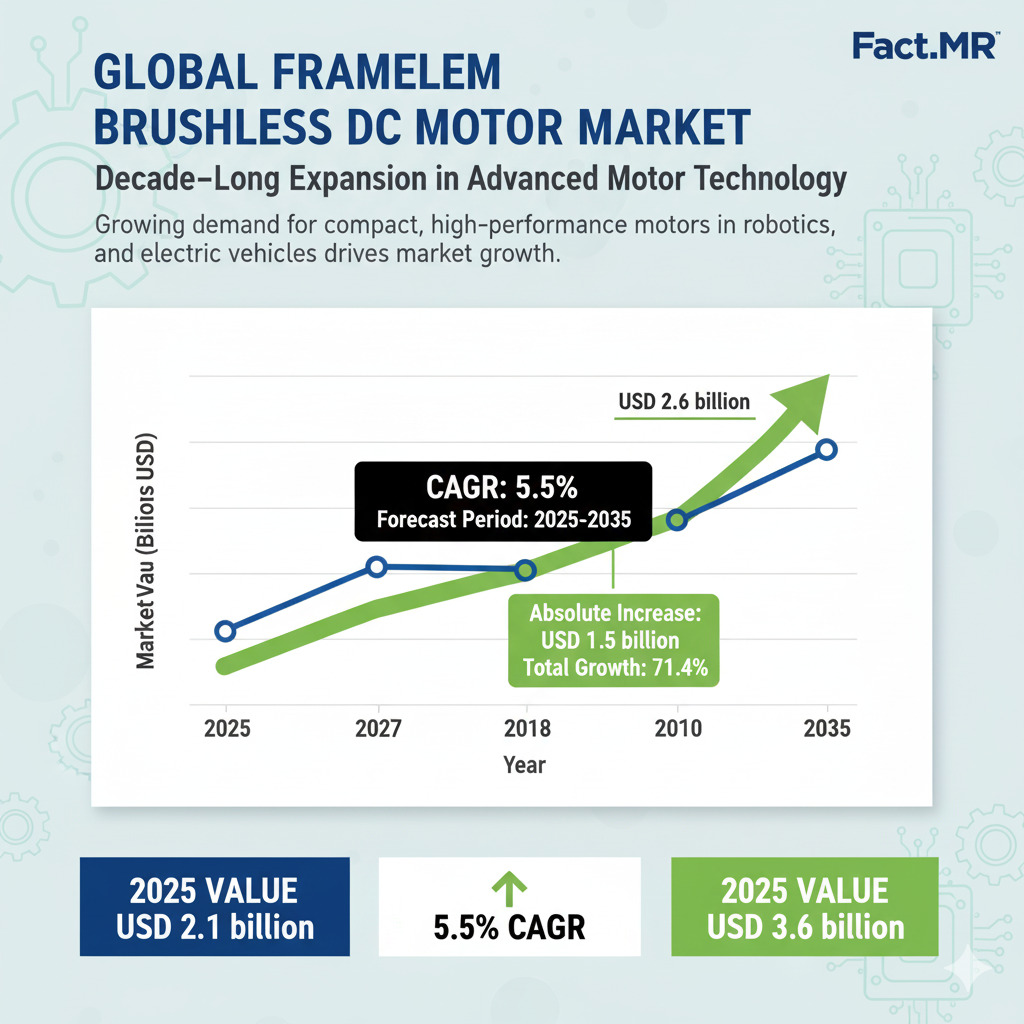

The global frameless brushless DC motor market is forecasted to reach USD 3.6 billion by 2035, recording an absolute increase of USD 1.5 billion over the forecast period. The market is valued at USD 2.1 billion in 2025 and is set to rise at a CAGR of 5.5% during the assessment period. This steady expansion—representing a 1.7x growth over ten years—reflects the rapid adoption of high-precision motion control systems, the rise of intelligent automation technologies, and the proliferation of robotics across industrial sectors.

Frameless brushless DC motors are becoming the foundation of next-generation automation systems, enabling superior torque density, compact design, and high efficiency. With efficiency rates ranging between 90–95%, these motors are revolutionizing industrial automation, aerospace, and robotics applications by offering enhanced performance without the need for substantial system redesigns.

Market Acceleration: The Decade of Motion Precision:

Between 2025 and 2030, the frameless brushless DC motor market will climb from USD 2.1 billion to USD 2.8 billion, accounting for 46.7% of the decade’s total growth. This phase will be marked by the widespread adoption of advanced robotics and precision automation solutions, as well as innovations in magnetic architecture and intelligent control systems.

From 2030 to 2035, the market will advance further to USD 3.6 billion, adding USD 0.8 billion, representing 53.3% of cumulative growth. This growth will be fueled by the integration of AI-driven motion controls, energy-efficient rotor configurations, and performance-optimized automation frameworks, particularly in Asia Pacific, North America, and Europe.

Key industry players—Maxon, Faulhaber, Kollmorgen, Portescap, Allied Motion, Nidec, and Moog—are investing in high-precision manufacturing and global expansion to strengthen their foothold in these markets.

Segmental Insights: Robotics Takes the Lead:

By Rotor Type: The inner-rotor segment leads the market with approximately 60% share in 2025, favored for its torque density and operational stability in compact automation systems. Advanced inner-rotor motors are increasingly integrated into robotics, aerospace systems, and high-speed industrial equipment, thanks to their balanced magnetic architecture and superior thermal performance. The outer-rotor segment, holding 40% share, caters to applications requiring high inertia and robust torque performance.

By Application: The robotics segment dominates with 30% share in 2025, driven by industrial automation, collaborative robots (cobots), and autonomous manufacturing systems. The industrial segment follows with 25%, while aerospace/defense, medical, and other specialized sectors collectively account for 45% of global demand.

This diversification underscores frameless BLDC motors’ ability to support wide-ranging performance requirements—from surgical robotics to unmanned aerial systems and advanced manufacturing platforms.

By Voltage: The 24–60V range accounts for 50% share of total sales, enabling optimal power-to-performance ratios across general automation and industrial applications. The <24V range caters to compact, battery-operated devices, while >60V motors support heavy-duty automation and aerospace applications.

Regional Dynamics: Asia-Pacific Leads Global Expansion:

– Asia-Pacific dominates the frameless BLDC motor landscape, led by India (7.0% CAGR) and China (6.5% CAGR).

– India’s growth is fueled by automation-driven manufacturing reforms under the Make in India initiative, establishing advanced motion control ecosystems in hubs like Pune, Bangalore, and Chennai.

– China’s market is boosted by Made in China 2025, emphasizing industrial modernization and precision manufacturing upgrades in regions like Shenzhen and Shanghai.

– North America, led by the United States (5.0% CAGR), continues to invest in automation modernization, with case studies showing 30% productivity gains from integrating frameless BLDC systems into legacy production lines.

– Europe remains a technology hub, with Germany (4.8% CAGR) maintaining leadership through engineering excellence and quality assurance standards.

South Korea (4.5%) and Japan (3.5%) showcase strong precision manufacturing integration and continuous improvement programs across motor control systems.

Competitive Landscape: Innovation as the Core Differentiator:

The frameless BLDC motor market exhibits moderate concentration, with the top three companies controlling around 35–45% of global share.

– Maxon, Faulhaber, and Kollmorgen lead through innovation, advanced manufacturing, and strong industry relationships.

– Allied Motion, Portescap, and Nidec are gaining traction via regional specialization and modular motor design.

– Emerging players from India and China are introducing localized solutions, strengthening supply chain resilience and cost optimization.

Competition increasingly centers on technological innovation and lifecycle support rather than price. Manufacturers are focusing on enhanced torque density, intelligent control integration, and modular design systems to meet evolving automation demands.

Market Drivers and Challenges:

Key Growth Drivers:

– Rising Automation Adoption: Industrial automation and robotics installations are growing 8–12% annually across developing economies, driving motor demand.

– Government Manufacturing Initiatives: Global policy programs promoting smart manufacturing and Industry 4.0 are propelling adoption.

-Technological Advancements: Modern motor designs enable simplified integration, predictive maintenance, and efficiency optimization.

Challenges:

High R&D costs, complex integration requirements, and the need for specialized expertise continue to pose barriers, especially for small and mid-sized automation firms.

Strategic Imperatives for Stakeholders:

For Governments: Provide tax incentives for precision motor production and fund R&D programs supporting advanced automation.Develop streamlined certification processes for motor performance and training programs for motion control engineers.

For Industry Bodies: Establish performance standards and certification frameworks for frameless motor systems.Promote best practices highlighting efficiency and sustainability benefits.

For Manufacturers: Invest in next-generation motor design, enhancing torque density and integration capabilities.Develop intelligent monitoring systems to support predictive maintenance and long-term reliability.Build regional support and training networks to strengthen end-user adoption and operational performance.

A Transformational Decade for Precision Motion Systems:

The frameless brushless DC motor market’s steady climb to USD 3.6 billion by 2035 underscores its critical role in the evolution of industrial automation and robotics. As manufacturers embrace intelligent, compact, and high-efficiency motion systems, frameless BLDC motors are set to become indispensable components in the future of smart manufacturing.

Industry leaders that prioritize innovation, integration, and intelligence stand to shape the future of motion control technology—defining the next era of automation excellence.

Browse Full Report-https://www.factmr.com/report/frameless-brushless-dc-motor-market