The Flow Conditioners Market is gaining increasing importance as industries strive for greater precision and efficiency in fluid measurement systems. Flow conditioners are mechanical devices installed in pipelines to eliminate swirl, turbulence, and irregular flow patterns before fluids reach flow meters. By ensuring a stable and predictable flow profile, these devices significantly improve measurement accuracy and operational reliability.

As industries such as oil & gas, water treatment, chemicals, and power generation depend heavily on accurate flow measurement, the demand for advanced flow conditioning solutions continues to grow. With expanding industrial infrastructure and stricter regulatory requirements, flow conditioners are becoming essential components in modern pipeline systems.

Market Overview

Flow conditioners are typically installed upstream of flow meters to correct distorted flow profiles caused by bends, valves, reducers, or other obstructions in piping systems. These devices help achieve uniform velocity distribution, which is critical for accurate measurement and efficient process control.

The market includes various types of flow conditioners, including perforated plate designs, tube bundle conditioners, and vane-type configurations. Each design serves specific industrial requirements based on pipeline diameter, fluid type, pressure conditions, and installation constraints.

Growing industrial automation and the need for precise billing and custody transfer applications are driving demand for flow conditioners. Industries require reliable measurement systems to optimize resource usage, reduce operational losses, and comply with international standards.

Key Market Drivers

Rising Demand for Accurate Flow Measurement

Industries such as oil & gas and chemicals rely on accurate flow measurement for financial transactions, process efficiency, and regulatory compliance. Even minor inaccuracies can result in significant operational and financial implications. Flow conditioners help maintain measurement integrity by stabilizing fluid flow before it reaches metering devices.

Expansion of Oil & Gas Infrastructure

Pipeline networks are expanding globally to meet increasing energy demand. Flow conditioners play a crucial role in ensuring precise flow measurement during transportation and custody transfer of hydrocarbons. As upstream and downstream activities grow, the need for reliable pipeline components is increasing.

Growth in Water and Wastewater Management

Municipal and industrial water treatment facilities require accurate monitoring of water flow to manage resources effectively. Flow conditioners enhance the performance of flow meters in water distribution and wastewater systems, supporting operational efficiency.

Increasing Industrial Automation

Automation in manufacturing and processing plants requires accurate data for process control and monitoring. Flow conditioners contribute to reliable instrumentation systems by improving flow stability, thereby enhancing overall plant performance.

Regional Insights

North America

North America remains a prominent market for flow conditioners due to strong oil & gas operations and advanced industrial infrastructure. Regulatory emphasis on accurate measurement and safety compliance supports consistent demand in the region.

Europe

Europe’s focus on energy efficiency, environmental compliance, and industrial modernization drives the adoption of advanced flow measurement solutions. The presence of established manufacturing and chemical industries further strengthens market growth.

Asia-Pacific

The Asia-Pacific region is experiencing rapid industrialization and infrastructure expansion. Increasing investments in power generation, refining, and water treatment projects are contributing to growing demand for flow conditioning equipment.

Middle East & Africa

The Middle East, known for its extensive oil & gas reserves, presents significant opportunities for flow conditioner manufacturers. Expanding pipeline networks and energy infrastructure projects are key growth drivers in this region.

Key Trends & Forecast

Development of Compact Designs

Manufacturers are focusing on designing compact and lightweight flow conditioners to address space constraints in pipeline installations. These designs reduce installation costs and improve adaptability in complex piping systems.

Integration with Advanced Metering Technologies

As flow meters become more sophisticated, the compatibility between meters and conditioning devices is increasingly important. Flow conditioner manufacturers are developing solutions that enhance the performance of ultrasonic and other advanced metering systems.

Emphasis on Material Innovation

Corrosion-resistant and high-strength materials are being used to improve durability and extend product lifespan. Advanced alloys and engineered materials help flow conditioners withstand harsh operating conditions.

Focus on Energy Efficiency

Reducing pressure drop while maintaining flow accuracy is a major industry focus. Modern flow conditioners are designed to optimize energy efficiency without compromising performance.

Applications & End-Use Outlook

Oil & Gas Industry

In the oil & gas sector, flow conditioners are widely used in pipelines for custody transfer and process measurement. Accurate measurement is critical for operational efficiency and commercial transactions.

Power Generation

Power plants require precise monitoring of steam, gas, and water flow to maintain system efficiency. Flow conditioners help ensure reliable measurement in high-pressure environments.

Chemical Processing

Chemical plants operate under controlled flow conditions for various production processes. Flow conditioners enhance process stability and measurement reliability.

Water and Wastewater Treatment

Municipal water systems and industrial wastewater facilities depend on accurate flow monitoring to manage resources effectively. Flow conditioners support consistent performance of flow meters in these applications.

Competitive Landscape

The flow conditioners market is characterized by the presence of specialized manufacturers offering customized solutions tailored to specific industrial needs. Companies compete based on product quality, technical expertise, and compliance with international standards.

Innovation, product development, and strategic collaborations are common growth strategies. Manufacturers are focusing on research and development to enhance performance, reduce pressure drop, and improve compatibility with modern metering systems.

Future Outlook

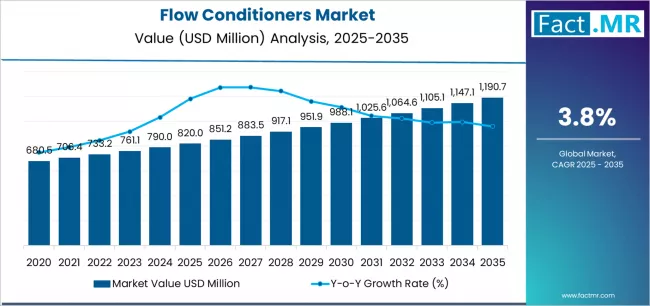

The future of the flow conditioners market appears promising as industries continue to prioritize accurate measurement and operational efficiency. Expanding pipeline networks, industrial automation, and energy infrastructure development will remain key growth drivers.

Technological advancements in materials and design are expected to shape the competitive landscape. As sustainability and energy efficiency become central to industrial operations, flow conditioners will play a crucial role in optimizing fluid management systems.

Conclusion

The flow conditioners market is an integral part of modern industrial measurement systems. By ensuring stable and accurate fluid flow, these devices enhance operational efficiency and regulatory compliance across multiple sectors. With growing industrial expansion and increasing demand for precise measurement, the market is positioned for steady growth in the coming years. Companies that focus on innovation, durability, and integration with advanced metering technologies are likely to lead the evolving market landscape.

Browse Full Report – https://www.factmr.com/report/flow-conditioners-market