The global Dynamic Signal Analyzer Market is expected to witness robust growth through 2036 as industries increasingly adopt advanced signal analysis tools to improve equipment reliability, enhance product quality, and support predictive maintenance strategies. Dynamic signal analyzers play a key role in measuring, processing, and interpreting vibration, noise, shock, and other dynamic signals in mechanical, electrical, and structural systems. These instruments are critical in sectors such as aerospace, automotive, industrial manufacturing, energy, and research laboratories, where precise signal characterization is essential for diagnostics, troubleshooting, and design validation.

Dynamic signal analyzers are sophisticated instruments that combine high-speed data acquisition with advanced frequency and time-domain analysis capabilities. They provide accurate insights into system behavior under operating conditions, enabling engineers to identify faults, optimize performance, and reduce downtime. With increasing emphasis on condition-based monitoring, predictive analytics, and quality control, the demand for dynamic signal analysis solutions is gaining momentum across end-use industries.

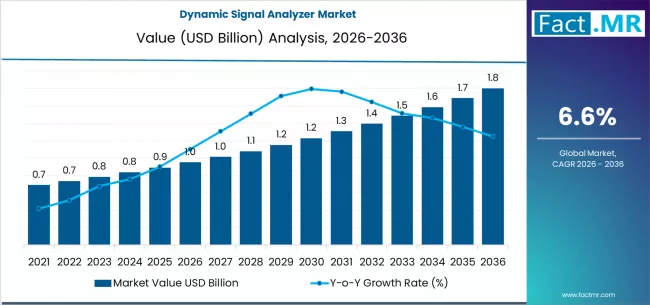

Market Outlook (2026–2036)

-

Market Value in 2026: USD 522.3 Million

-

Market Value in 2036: USD 1,137.8 Million

-

Forecast CAGR (2026–2036): 8.6%

-

Leading Analyzer Type: Portable Dynamic Signal Analyzers

-

Top End-Use Industries: Industrial Manufacturing and Automotive

The market is projected to expand steadily as advanced sensing and analysis become integral components of digital transformation and Industry 4.0 initiatives.

To access the complete data tables and in-depth insights, request a Discount On The Report here: https://www.factmr.com/connectus/sample?flag=S&rep_id=13199

Market Overview

Dynamic signal analyzers measure and evaluate signals across time and frequency domains to detect anomalies, characterize vibrations, and assess structural and mechanical behavior. They are widely used for condition monitoring, noise and vibration analysis, modal testing, rotating machinery diagnostics, and product development testing. Integration with sensors, data loggers, and analytics software enhances their utility, allowing real-time data interpretation and trend analysis for preventive maintenance.

Modern dynamic signal analyzers offer features such as high sampling rates, FFT (Fast Fourier Transform) processing, real-time spectral display, and automated alarming. These capabilities make them indispensable for engineers and technicians seeking to maintain equipment efficiency, extend asset life, and prevent catastrophic failures. As manufacturing industries adopt smart systems and predictive maintenance practices, dynamic signal analyzers are becoming key tools in performance monitoring solutions.

Key Market Drivers

1. Expansion of Predictive Maintenance and Condition Monitoring

Industries are moving away from reactive maintenance toward predictive maintenance strategies that rely on real-time data and signal analysis to identify early signs of equipment failure. Dynamic signal analyzers support this transition by providing precise vibration, noise, and shock data critical for accurate diagnostics.

2. Industrial Automation and Industry 4.0 Initiatives

Industry 4.0 is driving investment in connected sensors, data analytics, and smart monitoring solutions. Dynamic signal analyzers are essential components of these ecosystems, enabling integration of vibration and acoustic data into broader asset management and analytics platforms.

3. Quality Assurance and Product Development Needs

Automotive, aerospace, consumer electronics, and machinery manufacturers use dynamic signal analysis during design validation and quality assurance testing to ensure product performance, durability, and compliance with industry standards.

4. Regulatory Compliance and Safety Standards

Stringent regulatory requirements for equipment safety, noise levels, and performance in industries such as transportation, energy, and construction are encouraging adoption of dynamic signal measurement and analysis systems.

Market Segmentation Insights

By Analyzer Type:

-

Portable Dynamic Signal Analyzers

-

Bench-Mounted Analyzers

-

PC-Based Signal Analyzer Systems

-

Integrated Analyzer Modules

By Frequency Range:

-

Low Frequency

-

Medium Frequency

-

High Frequency

-

Ultrasonic Range

By End-Use Industry:

-

Industrial Manufacturing

-

Automotive

-

Aerospace and Defense

-

Energy and Utilities

-

Research and Academic Institutions

-

Consumer Electronics and Appliances

By Distribution Channel:

-

Direct Sales to Original Equipment Manufacturers

-

Industrial Distributors

-

Authorized Resellers

-

Online Sales Platforms

Regional Demand Dynamics

North America is expected to remain a dominant region for dynamic signal analyzers due to advanced manufacturing infrastructure, high adoption of condition monitoring solutions, and strong presence of key analyzer manufacturers. The United States and Canada are significant contributors to market demand driven by aerospace, automotive, and industrial automation sectors.

Europe is another important market, supported by robust automotive and machinery manufacturing industries and regulatory standards emphasizing safety and performance. The adoption of sensor-based predictive maintenance systems across European industries further supports market growth.

Asia Pacific is projected to exhibit rapid growth, fueled by industrial expansion, increasing automation in manufacturing, and rising investment in predictive maintenance technologies. Countries such as China, Japan, South Korea, and India are key contributors to regional market demand.

Latin America and Middle East & Africa are anticipated to show steady growth as industrial sectors modernize, and demand for advanced monitoring and diagnostic tools rises with infrastructure development and asset optimization efforts.

Competitive Landscape

The dynamic signal analyzer market is moderately competitive, featuring global instrumentation manufacturers, industrial analytics solution providers, and electronics companies. Market participants are focused on enhancing analyzer performance, improving software integration, expanding global distribution networks, and delivering value-added support services.

Innovation efforts include development of real-time analysis features, rugged portable units for field applications, and seamless connectivity with data management and cloud platforms. Companies also emphasize customer education, service contracts, and customized solutions to address diverse industrial needs.

Future Outlook

The Dynamic Signal Analyzer Market is expected to sustain strong momentum through 2036 as industries continue to adopt advanced monitoring and diagnostic tools to optimize operations, reduce downtime, and improve product quality. With growing emphasis on digital transformation, predictive maintenance, and smart factory frameworks, dynamic signal analysis solutions will remain central to performance evaluation and condition monitoring strategies across global industrial landscapes.

Continued advancements in analyzer technologies and rising demand for integrated monitoring systems will further propel market expansion, enhancing the value proposition of dynamic signal analyzers in a rapidly evolving technological ecosystem.

Browse Full Report: https://www.factmr.com/report/dynamic-signal-analyzer-market