Crushing equipment plays a pivotal role in mining, construction, and aggregate production by reducing large rocks and ores into smaller, manageable materials for downstream processes. These machines form the backbone of operations in industries that require consistent size reduction, enabling efficient material handling, improved productivity, and cost optimization.

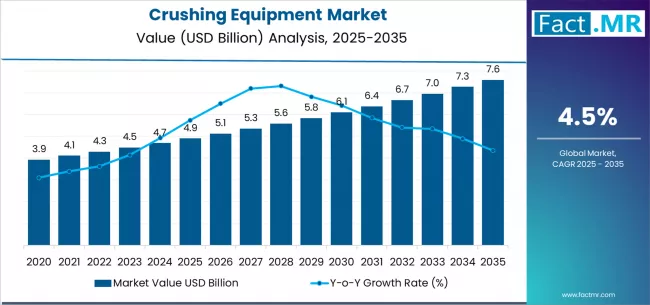

As global infrastructure development accelerates and the demand for minerals and aggregates rises, the crushing equipment market is expanding rapidly. Innovations in design, automation, and energy efficiency are transforming crushing machines into smarter, safer, and more sustainable solutions that cater to modern industrial requirements.

Market Overview

Crushing equipment encompasses a wide range of machines, including jaw crushers, cone crushers, impact crushers, and gyratory crushers, each designed to handle specific types of materials and applications. These machines are crucial in mining operations, quarries, construction projects, and recycling processes, ensuring optimal size reduction for further processing or use.

Modern crushing equipment emphasizes durability, operational efficiency, and low maintenance. Manufacturers are adopting advanced materials for wear components, improved automation for better throughput control, and energy-efficient motors to reduce operational costs. Additionally, portable and modular crusher designs are enabling flexible deployment in remote or challenging locations, reducing project downtime and improving productivity.

Regional Insights

The crushing equipment market exhibits diverse adoption patterns, influenced by regional industrial growth, mining activities, and infrastructure development:

- North America maintains a significant market share due to strong construction activity, aggregate demand, and modernization of mining infrastructure. High safety and emission standards are driving the adoption of advanced, automated crushing solutions.

- Europe demonstrates steady growth driven by infrastructure modernization, road and bridge construction projects, and environmentally friendly crushing solutions. Germany, France, and the UK are leading adopters of high-efficiency crushing systems.

- Asia Pacific is emerging as the fastest-growing region, propelled by urbanization, industrialization, and the expansion of mining operations in countries such as China, India, and Australia. Demand for high-performance and large-capacity crushers is particularly high in this region.

- Middle East & Africa are witnessing rising adoption due to large-scale mining operations, infrastructure development, and growing construction activity. Mining-heavy economies are investing in modern crushing equipment to improve production efficiency.

The global demand reflects a combination of mature markets with replacement and retrofit needs and emerging regions with new infrastructure and mining projects.

Key Trends & Forecast

The crushing equipment market is evolving under several transformative trends:

- Automation and Smart Monitoring: Crushing machines equipped with digital sensors and monitoring systems enable predictive maintenance, reduce downtime, and optimize operational efficiency. Real-time analytics allows operators to track performance and detect issues before failure occurs.

- Energy-Efficient Designs: Manufacturers are incorporating energy-saving motors, improved material flow mechanisms, and advanced control systems to reduce energy consumption and operational costs.

- Mobile and Portable Crushers: Growing demand for flexible operations in mining and construction sites is driving adoption of mobile and modular crushing solutions, which can be easily transported and deployed on-site.

- Advanced Wear-Resistant Materials: Use of high-strength alloys and composite materials for wear parts extends equipment life, reduces maintenance intervals, and lowers total cost of ownership.

- Integration with Sustainable Practices: Environmentally conscious operations are adopting crushing equipment with noise reduction, dust suppression, and emissions control features, aligning with sustainability goals and regulatory requirements.

These trends indicate a shift toward smarter, safer, and more sustainable crushing solutions, enhancing productivity and cost-effectiveness.

Applications & End-Use Outlook

Crushing equipment serves a wide spectrum of industrial applications, delivering efficiency and reliability:

- Mining Industry: Crushers process ores like coal, gold, iron, and copper to prepare them for extraction, refining, and downstream processing. High-capacity equipment ensures consistent output while minimizing operational downtime.

- Construction and Infrastructure: Jaw and cone crushers are widely used in the production of aggregates for roads, bridges, buildings, and other infrastructure projects, ensuring material quality and uniformity.

- Recycling Operations: Crushing machines are employed in recycling concrete, asphalt, and demolition waste, contributing to sustainable construction practices and resource efficiency.

- Quarrying: Crushing equipment facilitates the production of sand, gravel, and stone aggregates, supporting both local and large-scale construction needs.

- Industrial Material Processing: Certain industries, such as cement, glass, and chemical manufacturing, utilize crushers for size reduction of raw materials, improving process efficiency and product quality.

The adaptability of crushing equipment across multiple sectors underscores its critical role in modern industrial operations.

Competitive Landscape

The crushing equipment market is characterized by a mix of global manufacturers, regional producers, and specialized solution providers. Leading players focus on technological innovation, durability, and after-sales service to differentiate themselves.

Companies are investing in R&D to develop energy-efficient, digitally monitored, and environmentally friendly crushing solutions. Strategic collaborations with construction, mining, and industrial firms help deliver customized solutions that meet specific operational requirements. Additionally, aftermarket services such as maintenance, spare parts supply, and operator training are becoming crucial for maintaining long-term customer relationships and ensuring equipment longevity.

With competition intensifying, companies that integrate automation, safety, and sustainability into their offerings are expected to maintain a competitive edge in the market.

Conclusion

The crushing equipment market is experiencing robust growth as global demand for minerals, aggregates, and construction materials continues to rise. Advanced design, automation, and sustainability are transforming these machines into high-performance, low-maintenance solutions that cater to the evolving needs of mining, construction, and industrial sectors.

As infrastructure development accelerates worldwide, manufacturers and end-users are increasingly prioritizing equipment that combines efficiency, durability, and environmental compliance. Crushing equipment not only enhances operational productivity but also enables safer, more sustainable, and cost-effective industrial processes.

In an era defined by urbanization, industrial growth, and sustainable development, crushing equipment remains a critical enabler of progress—powering industries and infrastructure projects across the globe with reliability, efficiency, and innovation.

Browse Full Report – https://www.factmr.com/report/crushing-equipment-market