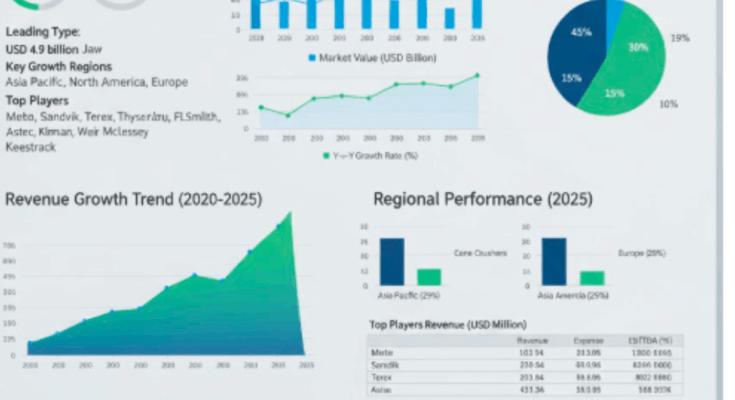

The Crushing Equipment Market is experiencing steady growth as mining operators, construction companies, and recycling facilities adopt advanced crushing technologies to enhance material processing efficiency. The global market was valued at USD 4.9 billion in 2025 and is expected to reach USD 7.6 billion by 2035, registering a CAGR of 4.5%. The demand is driven by large-scale mining operations, infrastructure development projects, and the need for specialized equipment to optimize processing efficiency and operational safety.

Crushing equipment, including jaw, cone, and impact crushers, enables efficient material reduction, maintains consistent particle sizes, and supports high-capacity operations. Advanced technologies integrated into modern crushing systems allow operators to meet increasingly complex mining and construction requirements while minimizing maintenance and operational costs.

Market Analysis & Trends

The Crushing Equipment Market growth is underpinned by several key trends:

-

Mining Expansion – Rising demand for minerals and ores drives the adoption of specialized crushing systems that improve throughput and reliability. Mining accounts for approximately 55% of market share in 2025, reflecting its critical role.

-

Construction & Infrastructure Development – The growth of construction aggregates and large-scale infrastructure projects fuels demand for high-performance crushing equipment, particularly in Asia Pacific, North America, and Europe.

-

Technological Advancements – Automated and integrated crushing systems improve operational efficiency, reduce downtime, and enhance material handling capabilities.

-

Recycling Applications – Demand for sustainable and cost-effective material processing solutions contributes to the adoption of crushing equipment in recycling operations, accounting for 10% market share.

Opportunities: Expanding electric and automated crushing solutions, adoption in emerging markets like India (CAGR 6.2%) and China (CAGR 5.4%), and integration with mineral processing platforms.

Challenges: High initial costs, technical complexity, and specialized maintenance requirements for high-capacity crushing systems.

Segmental Analysis

By Equipment:

-

Jaw Crushers: Dominant segment with 35% market share, used for primary crushing operations across mining and construction.

-

Cone Crushers: Capture 30% market share, suitable for secondary crushing of hard materials.

-

Impact Crushers: Serve 20% of the market, focused on tertiary applications.

By End Use:

-

Mining (55%)

-

Construction Aggregates (35%)

-

Recycling (10%)

By Mobility:

-

Stationary (60%)

-

Mobile/Portable (40%)

By Region:

-

Asia Pacific (India, China, Japan, South Korea)

-

North America (USA, Mexico)

-

Europe (Germany, UK, France, Italy, Spain)

-

Latin America, Middle East & Africa

Competitive Landscape / Key Players

The Crushing Equipment Market is moderately consolidated, with top players driving innovation and expansion:

-

Metso – Leading in advanced jaw and cone crushers with automated monitoring systems.

-

Sandvik – Offers high-capacity crushing equipment with integrated processing platforms.

-

Terex – Focuses on mobile and stationary crushing systems for mining and construction.

-

Thyssenkrupp, Astec, FLSmidth, Kleemann, Weir, McCloskey, Keestrack – Provide specialized equipment and regional support.

Companies compete through technology innovation, operational efficiency, and strategic partnerships with mining and construction operators. Emerging regional players in India and China leverage local expertise and cost advantages to expand market reach.

Regional Growth Insights

-

India: Fastest-growing market with CAGR of 6.2%, driven by infrastructure expansion, government-backed mining initiatives, and modern processing systems.

-

China: Growing at 5.4% CAGR, supported by construction modernization and industrial scaling.

-

USA & Germany: Steady growth at 3.6% and 3.5% CAGR, focusing on mining innovation, operational optimization, and precision engineering.

-

South Korea & Japan: Emphasis on technology integration, advanced processing systems, and high-quality manufacturing standards.

-

Mexico: Emerging market with growing mining and construction applications.

Future Outlook

The Crushing Equipment Market is projected to continue growth through 2035, supported by:

-

Expansion of specialized mining and aggregate processing applications

-

Adoption of automated and smart crushing systems

-

Strategic collaborations between equipment manufacturers and industrial operators

-

Integration of advanced material handling and predictive maintenance technologies

Asia Pacific, led by India and China, will remain the primary growth engine, while North America and Europe focus on technological innovation and operational efficiency.

Browse Full report : https://www.factmr.com/report/crushing-equipment-market

For mining operators, construction companies, investors, and equipment manufacturers, the Crushing Equipment Market offers a compelling opportunity to optimize operations, improve throughput, and achieve competitive advantage.

Investing in advanced crushing systems allows companies to:

-

Enhance operational efficiency by 40–60% compared to conventional systems

-

Ensure compliance with safety and regulatory standards

-

Integrate specialized technologies for mining, construction, and recycling applications

Accessing comprehensive market insights and reports enables stakeholders to make informed decisions, identify growth opportunities, and strengthen their competitive positioning in this evolving industrial sector.