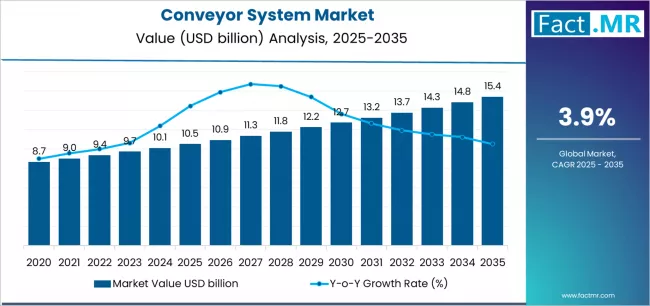

The global conveyor system market is poised for consistent expansion, supported by the rapid evolution of automation technologies, e-commerce logistics, and industrial modernization initiatives. According to a recent report by Fact.MR the market is projected to grow from USD 10.5 billion in 2025 to approximately USD 15.4 billion by 2035, reflecting an absolute increase of USD 4.9 billion over the forecast period. This translates into a total growth of 46.7%, with the market forecast to expand at a compound annual growth rate (CAGR) of 3.9% between 2025 and 2035.

As industries worldwide focus on operational efficiency, worker safety, and production throughput, conveyor systems have become indispensable across manufacturing, warehousing, and logistics operations.

Strategic Market Drivers

- Rising Automation and Smart Factory Integration

Industrial automation is reshaping global production systems. Conveyor systems are increasingly integrated with robotics, sensors, and AI-driven controls, enabling predictive maintenance, real-time monitoring, and seamless data exchange. These advancements are vital to the Industry 4.0 movement, where automated material handling enhances throughput and reduces human intervention in high-volume operations. - Surge in E-Commerce and Intralogistics Efficiency

The exponential growth of e-commerce is fueling demand for efficient order fulfillment centers. Automated conveyor systems—equipped with barcode readers, diverters, and smart sortation modules—are crucial in managing high-speed inventory movement and last-mile logistics. Global retailers and third-party logistics providers are adopting advanced conveyor technologies to improve delivery accuracy and warehouse productivity. - Expansion in Food & Beverage and Pharmaceutical Sectors

The need for hygiene, speed, and compliance in food processing and pharmaceuticals has accelerated conveyor adoption. Stainless steel and modular belt conveyors are gaining popularity for their wash-down capabilities and contamination control, ensuring product safety and regulatory compliance. - Sustainability and Energy Efficiency Initiatives

Manufacturers are prioritizing energy-efficient conveyor designs, utilizing low-friction materials, regenerative drives, and variable frequency motors to minimize power consumption. The shift toward green logistics and carbon-neutral operations is encouraging companies to adopt conveyors with optimized load capacity and reduced maintenance requirements.

Browse Full Report: https://www.factmr.com/report/4779/conveyor-system-market

Regional Growth Highlights

East Asia: The Automation Powerhouse

East Asia leads the global conveyor system market, driven by strong industrial bases in China, Japan, and South Korea. Continuous investments in manufacturing automation, automotive production, and consumer electronics are propelling regional growth. The rise of smart logistics parks and automated warehouses reinforces East Asia’s leadership in conveyor innovation.

North America: Driven by Digital Transformation and E-Commerce Growth

The U.S. and Canada are experiencing rapid conveyor adoption in distribution centers and production facilities. The boom in online retail, food logistics, and advanced manufacturing is spurring large-scale system upgrades. Regional players are integrating IoT-enabled conveyor systems that enhance performance visibility and reduce downtime.

Europe: Precision Engineering and Sustainability Focus

Europe remains a hub for innovative conveyor technologies, emphasizing modular design, energy savings, and material recyclability. Germany, the U.K., and the Netherlands are witnessing high conveyor system demand across automotive, packaging, and parcel delivery industries, underpinned by stringent energy and safety regulations.

Emerging Economies: Infrastructure and Industrialization Boost

Countries in Latin America, South Asia, and the Middle East are rapidly investing in infrastructure, logistics, and manufacturing. Government-driven industrialization programs and foreign investments are creating new opportunities for conveyor suppliers, particularly in automotive assembly, mining, and port operations.

Market Segmentation Insights

By Conveyor Type:

- Belt Conveyors: Dominant segment, widely used in logistics and manufacturing.

- Roller Conveyors: Gaining traction for packaging and pallet handling applications.

- Overhead Conveyors: Ideal for automotive and apparel manufacturing lines.

- Pallet Conveyors: Increasing adoption in heavy-duty industrial assembly.

- Floor Conveyors: Common in warehouses for optimized space utilization.

By End-Use Industry:

- Automotive: Expanding use in assembly and parts movement.

- Food & Beverage: Rising demand for hygienic conveyors and sanitary systems.

- Retail & Distribution: Growing installation in e-commerce fulfillment centers.

- Airport & Parcel Handling: Driven by rising air travel and global logistics activity.

- Mining & Manufacturing: Adoption of heavy-load and durable conveyor solutions.

Challenges and Market Considerations

Despite strong growth momentum, several factors could influence market performance:

- High Initial Investment Costs: Advanced conveyor automation requires substantial capital expenditure.

- Maintenance and Downtime Risks: Equipment reliability and timely servicing are critical for high-throughput environments.

- Complex Integration with Legacy Systems: Older production setups pose compatibility challenges with modern conveyor technologies.

- Fluctuating Raw Material Prices: Variations in steel and polymer costs impact manufacturing budgets.

Competitive Landscape

The global conveyor system market is characterized by technology-driven competition and expanding global footprints. Leading companies are investing in digital conveyor control systems, predictive analytics, and custom-engineered solutions for diverse industrial needs.

Key Players in the Conveyor System Market:

- Daifuku

- Dematic

- SSI Schäfer

- Vanderlande

- Interroll

- Fives Intralogistics

- BEUMER Group

- TGW Logistics

- Honeywell Intelligrated

- Bastian Solutions

These companies are enhancing supply chain connectivity and launching advanced conveyor solutions to support high-volume, automated operations globally.

Future Outlook: Toward Intelligent and Sustainable Material Flow

The next decade will redefine the conveyor system landscape through digitalization, modularity, and eco-efficiency. Intelligent conveyors—equipped with AI-based motion control, autonomous rerouting, and IoT-enabled diagnostics—are expected to dominate new installations.

With continued demand from e-commerce, automotive, and industrial sectors, the global conveyor system market is set for steady and resilient growth. Companies that align innovation with sustainability and operational intelligence will shape the future of material movement—driving a smarter, faster, and greener industrial ecosystem.