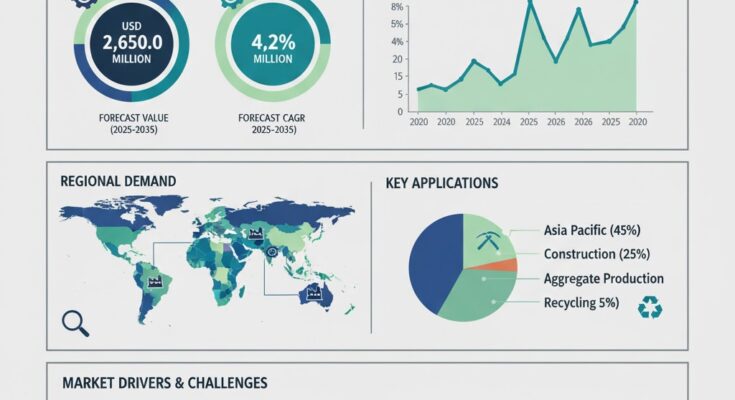

The global cone crushers market is on a steady upward trajectory, fueled by the increasing demand for efficient crushing equipment across mining, construction, and aggregate production industries. According to a recent report by Fact.MR, the market is projected to grow from USD 1,750.0 million in 2025 to approximately USD 2,650.0 million by 2035, recording an absolute increase of USD 900.0 million over the forecast period. This translates into a total growth of 51.4%, with the market forecast to expand at a CAGR of 4.2% between 2025 and 2035.

Market Overview

Cone crushers, integral to the rock crushing process, are engineered to handle hard and abrasive materials with precision and high efficiency. These machines are essential across multiple sectors—from mining and metallurgy to infrastructure and recycling—owing to their ability to deliver uniform particle size and superior throughput. The market’s growth is underpinned by surging infrastructure development, increasing mining output, and the modernization of processing facilities across both developed and emerging economies.

As global construction activities intensify and mineral extraction expands, demand for advanced, energy-efficient cone crushers is expected to rise steadily.

Strategic Market Drivers

- Expanding Mining and Quarrying Activities

The global surge in mining exploration and quarrying operations is a primary driver for cone crusher demand. With rising extraction of metals, aggregates, and minerals, the need for reliable and durable crushing equipment is increasing. Cone crushers are preferred for their high crushing efficiency, reduced operational costs, and long service life—making them indispensable in large-scale mining applications.

- Infrastructure and Construction Boom

Massive investments in infrastructure projects, urbanization, and transportation networks are catalyzing growth in the cone crushers market. Governments worldwide are prioritizing road development, smart cities, and housing projects, all of which demand high-quality aggregates produced through efficient crushing systems.

- Technological Innovations in Crushing Efficiency

Manufacturers are integrating automation, digital monitoring, and hydraulic systems into cone crushers to enhance operational safety, precision, and performance. Smart sensors and real-time data analytics are enabling predictive maintenance, minimizing downtime, and extending machine life. Advanced cone crushers with variable speed controls and adjustable settings are becoming standard in modern mining operations.

- Shift Toward Energy-efficient and Sustainable Operations

As environmental regulations tighten, the industry is witnessing a shift toward low-emission and energy-saving crushing technologies. Hybrid and electric-powered cone crushers are gaining popularity, helping reduce carbon footprints while maintaining high productivity.

Regional Growth Highlights

East Asia: The Core of Global Growth

East Asia dominates the cone crushers market, driven by rapid industrialization, massive infrastructure development, and expanding mining activities in China. Japan and South Korea’s technological expertise and focus on precision engineering further contribute to the region’s leadership position.

North America: Innovation and Automation Hub

North America remains a key market for technologically advanced crushers, supported by strong mining operations and infrastructure investments. The U.S. is witnessing growing adoption of mobile and tracked cone crushers, particularly in quarrying and recycling applications.

Europe: Regulation and Efficiency Focus

European nations continue to emphasize energy-efficient and low-noise crushing solutions in compliance with stringent environmental standards. Countries like Germany, the UK, and Italy are advancing in sustainable mining practices, fueling adoption of automated and eco-friendly cone crushers.

Emerging Economies: Latin America, South Asia, and Africa

Rapid urbanization and mining expansion in regions like India, Brazil, and South Africa present significant growth potential. Government initiatives for infrastructure modernization and mineral resource development are spurring demand for mid- to large-capacity cone crushers.

Market Segmentation Insights

By Mobility

- Stationary Cone Crushers dominate due to their widespread application in large-scale mining and quarrying operations.

- Portable and Mobile Crushers are gaining traction for on-site flexibility, especially in construction and recycling sectors.

By Application

- Mining remains the largest segment, driven by extraction of metals and aggregates.

- Construction and Demolition Recycling is emerging as a fast-growing application area, aligned with global sustainability goals.

By Power Source

- Diesel-powered crushers continue to lead in remote mining areas, while

- Electric and hybrid crushers are rapidly expanding due to operational cost savings and emission compliance.

Challenges and Market Considerations

Despite positive growth, the cone crushers market faces several challenges:

- High Capital Investment: Advanced crushing equipment entails substantial upfront costs.

- Maintenance Complexity: Wear and tear on liners and components necessitates regular servicing and skilled labor.

- Volatile Commodity Prices: Fluctuations in mineral prices can delay or reduce mining investments.

- Environmental Regulations: Strict emission and noise regulations require continuous product innovation.

Competitive Landscape

The cone crushers market is moderately consolidated, featuring both global giants and regional manufacturers focusing on technological excellence and strategic partnerships.

Key Players in the Cone Crushers Market

- Metso Outotec Corporation

- Sandvik AB

- Terex Corporation

- Thyssenkrupp AG

- Astec Industries, Inc.

- FLSmidth & Co. A/S

- Weir Group plc

- Kleemann GmbH (Wirtgen Group)

- Puzzolana Machinery Fabricators Pvt. Ltd.

- Propel Industries

- Telsmith Inc.

- McCloskey International

- Keestrack NV

- Komatsu Ltd.

- Eagle Crusher Company Inc.

These companies are investing in R&D to develop intelligent, energy-efficient crushers and expanding their global footprint through mergers, acquisitions, and strategic alliances.

Maufracture’s Strategic Positioning

Maufracture is aligning itself with the evolving industry landscape through:

- Innovation in Crushing Technology: Introducing next-generation cone crushers with enhanced automation, hydraulic control, and wear-resistant materials.

- Sustainability and Energy Efficiency: Developing electric-powered crushers to meet environmental and operational efficiency goals.

- Regional Expansion: Targeting emerging markets in Asia-Pacific, Latin America, and Africa to capitalize on infrastructure growth.

- Collaborative Partnerships: Working closely with mining and construction firms to provide tailored crushing solutions that optimize output and reduce downtime.

Future Outlook: Toward Smart, Sustainable Crushing Solutions

The decade ahead will witness a paradigm shift in the cone crushers market, marked by automation, digital intelligence, and sustainability. As the mining and construction sectors move toward smart operations, manufacturers who integrate performance optimization, environmental compliance, and cost efficiency will emerge as market leaders.

With a strong focus on innovation, sustainability, and customer-centric design, Maufracture is well-positioned to redefine industry standards—delivering reliable, intelligent, and energy-efficient crushing solutions for the modern era.