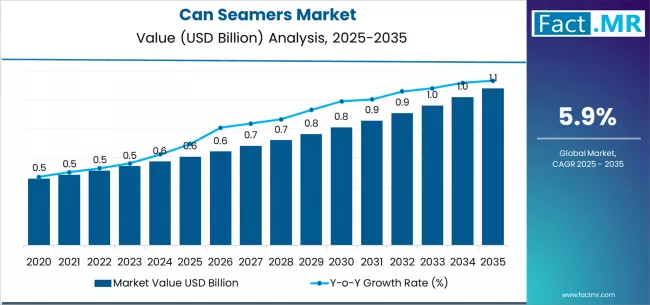

The global can seamers market is on track for steady expansion, driven by increasing demand for reliable, airtight sealing solutions in the food & beverage, pharmaceutical, chemical, and personal care industries. According to a new study by Fact.MR, the market is forecasted to grow from USD 0.61 billion in 2025 to USD 1.08 billion by 2035, marking a 95.5% increase and an absolute growth of USD 0.47 billion during the forecast period. The market is set to expand at a CAGR of 5.9% from 2025 to 2035, supported by automation, rising canned product consumption, and evolving safety standards in metal packaging.

The adoption of high-speed, energy-efficient, and automated seaming systems is transforming metal can packaging lines across global production facilities, reinforcing long-term demand for can seamers.

Strategic Market Drivers

Canned Consumption Gains Global Momentum

Growing consumer preference for shelf-stable and eco-friendly metal packaging continues to drive demand for canned beverages, processed foods, infant nutrition, pet food, sauces, seafood, edible oils, and ready-to-eat meals. The need for leak-proof, contamination-free, and tamper-evident sealing is accelerating investments in advanced can seaming technologies.

Browse Full Report: https://www.factmr.com/report/can-seamers-market

Packaging Line Automation Accelerates Adoption

The shift toward automated manufacturing lines is increasing the demand for automatic and semi-automatic high-speed can seamers. Seamers equipped with intelligent control systems offer:

- Consistent double-seam precision

- Reduced product wastage

- Higher throughput

- Improved operator safety

- Low maintenance downtime

These capabilities are making can seamers an essential part of modern metal packaging lines.

Food Safety and Regulatory Standards Push Technological Upgrades

Governments and industry regulators worldwide are enforcing strict packaging integrity mandates to ensure product safety. This is motivating manufacturers to transition toward servo-controlled, sensor-enabled, and digitally monitored seaming equipment for defect reduction and optimized performance.

Growth Across Non-Food Industrial Applications

Beyond food and beverages, can seamers are increasingly deployed in:

- Pharmaceutical & medical nutrition sealing

- Chemicals and paints

- Aerosols and personal care tins

- Industrial lubricants and fuel additives

The demand from non-food categories is widening the scope of the global seamer ecosystem.

Regional Growth Highlights

North America: Premium Seaming Automation Hub

High per-capita canned beverage and food demand, mature metal packaging infrastructure, and automation investments are making the U.S. and Canada strong growth markets. The region is prioritizing smart, high-precision seaming systems integrated with digital monitoring technologies.

Europe: Sustainability and Packaging Integrity Focus

Countries such as Germany, France, Italy, Spain, and the U.K. are recording rising demand due to:

- Growth of craft beverages and canned carbonated drinks

- Sustainable packaging initiatives

- Strong pet food and nutrition industries

- Mandatory food safety compliance

East Asia: Metal Packaging Production & Consumption Epicenter

China, Japan, and South Korea lead adoption due to:

- Massive food processing and beverage production plants

- Strong tin-can export networks

- Increased automation in packaging lines

- Rising seafood and RTE product demand

Emerging Markets: Manufacturing and Canned Beverages Uplift

India, ASEAN, GCC, and Latin American nations continue to adopt seamers owing to:

- Expansion of beverage bottling and canning lines

- Growth in local food processing units

- Rising startup ecosystem in canned juices and sparkling drinks

- Demand for compact and semi-automatic seamers in SMEs

Market Segmentation Insights

By Seamer Type

- Automatic Can Seamers – Largest segment as high-speed production lines scale

- Semi-Automatic Can Seamers – Popular among small and medium enterprises

- Manual Can Seamers – Maintains presence in micro-industry and pilot lines

By End-Use Industry

- Food & Beverage – Maximum adoption due to volume-driven canning lines

- Pharmaceuticals – Rising demand for medical nutrition and powdered sealing

- Personal Care & Aerosols – Increased industrial adoption

- Chemicals & Industrial Liquids – Expanding non-food usage segment

By Technology

- Traditional Mechanical Seamers

- Servo-Controlled Seamers with high seam precision

- Smart Sensor-Based Seamers with real-time monitoring

Challenges Impacting Market Growth

- Higher upfront equipment cost for automated seamers

- Need for skilled engineers for setup and maintenance

- Production sensitivity requiring regular quality calibration

Competitive Landscape

The can seamers market is moderately consolidated, with leading companies investing in:

- High-speed automated canning solutions

- Digital seam inspection and sensor-enabled monitoring

- Reduced-footprint designs for SME packing lines

- Energy-efficient and corrosion-resistant models

Key Companies Profiled

- Ferrum AG

- Krones AG

- Pneumatic Scale Angelus (Barry-Wehmiller)

- Cask Global Canning Solutions

- Imperial Machine Company (IMC)

- Filler Specialties, Inc.

- ProSeamer

- Dixie Canner Co.

Recent Developments

- Integration of real-time seam defect detection sensors in automated seamers

- Lightweight, low-power seamers designed for SME beverage startups

- Rise in mobile canning lines using compact semi-automatic seamers

Future Outlook: Smarter, Faster, and Safer Can Sealing

The next decade will witness continued transformation driven by:

- Rising consumption of canned beverages and ready-meals

- Automation in mass canning plants

- Evolution of digital seam inspection

- Demand for airtight, safe, eco-friendly metal packaging

As manufacturers prioritize production speed, sealing integrity, and automated quality control, the global can seamers market will continue strengthening through 2035.