The global bismuth market is entering a transformative decade of industrial expansion, forecasted to rise from USD 820 million in 2025 to USD 1.12 billion by 2035, reflecting a compound annual growth rate of 3.2 percent. This steady and sustained growth underscores the critical role bismuth plays in the modern industrial ecosystem—where advanced manufacturing, pharmaceutical innovation, and metallurgical precision converge to redefine performance standards and sustainability objectives across multiple sectors.

According to the latest Bismuth Market Forecast and Outlook 2025–2035, the market will grow by nearly 1.4 times over the forecast period, driven by rapid integration of bismuth-based materials into industrial alloys, electronic components, medical devices, and pharmaceutical compounds. Increasing global demand for high-purity metallurgical grades, coupled with continued investment in advanced refining and processing technologies, is reshaping the competitive landscape and positioning bismuth as a strategic enabler of next-generation manufacturing systems.

Between 2025 and 2030, the market is projected to expand from USD 820 million to USD 970 million, recording a value gain of USD 150 million. From 2030 to 2035, another USD 150 million is expected to be added, pushing the market to USD 1.12 billion. This consistent decade-long momentum is rooted in three major growth catalysts.

First, the development of advanced alloy systems has accelerated demand for high-purity bismuth. Its unique properties—non-toxicity, high density, and superior corrosion resistance—make it an ideal substitute for lead and other restricted metals in industrial production. Manufacturers are turning to bismuth to improve process safety, mechanical performance, and environmental compliance, especially as global regulations tighten around heavy metal use.

Second, the pharmaceutical sector is driving significant structural demand. High-purity bismuth compounds are being adopted in therapeutic and diagnostic applications, offering performance improvements of up to 60 percent over conventional materials. These compounds play a crucial role in gastrointestinal treatments, antimicrobial formulations, and diagnostic imaging, aligning with the broader trend toward precision medicine and pharmaceutical innovation.

Third, technological integration in manufacturing systems has expanded bismuth’s role beyond materials science. Industrial operators are embedding bismuth into automated production lines, ensuring consistent material performance, traceable quality assurance, and enhanced product reliability. This integration aligns with the ongoing modernization of manufacturing infrastructure across Asia-Pacific, Europe, and North America.

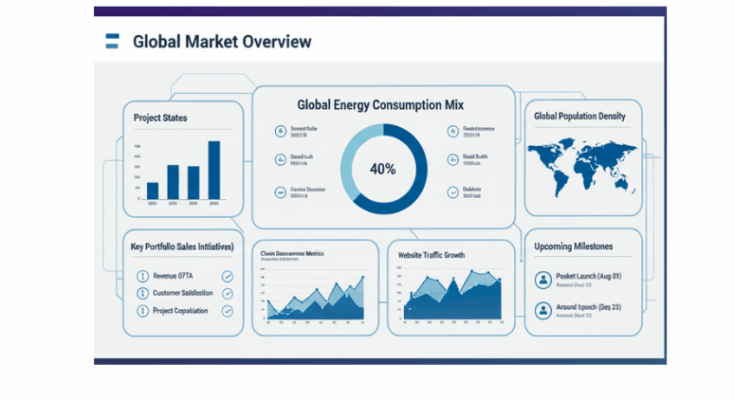

The metallurgical grade segment remains the cornerstone of the global market, accounting for approximately 40 percent of total value in 2025. Its dominance reflects its widespread application across industrial alloys and mechanical systems, where performance stability and process efficiency are paramount. Metallurgical-grade bismuth offers superior durability and mechanical integrity, enabling manufacturers to achieve optimal processing performance across diverse industrial applications.

The pharmaceutical grade follows closely with 35 percent market share, representing the expanding base of medical and biotechnology companies relying on high-purity bismuth compounds. These formulations are essential for meeting regulatory purity standards while supporting large-scale pharmaceutical production and medical device development. The chemical grade, which comprises around 25 percent of the market, continues to serve specialty industrial applications requiring precise chemical reactivity or tailored physical characteristics.

From an application perspective, bismuth alloys lead the market, accounting for about 35 percent of global demand in 2025. Their increasing use in low-melting solders, safety components, and advanced metallurgical composites underscores bismuth’s role in driving manufacturing innovation. The pharmaceutical sector also represents approximately 35 percent of market share, driven by the adoption of bismuth-based compounds in therapeutic formulations and medical technologies. Cosmetics applications account for about 20 percent, while remaining industrial uses represent 10 percent, serving diverse specialty segments.

Regionally, Asia-Pacific remains the epicenter of market growth, led by India and China. India, projected to record a 3.8 percent CAGR through 2035, benefits from a rapidly expanding manufacturing base, government-backed industrial programs, and strong pharmaceutical infrastructure. Major industrial cities such as Mumbai, Delhi, Bangalore, and Hyderabad are at the forefront of adopting bismuth systems for refining, production optimization, and medical manufacturing. China, growing at 3.5 percent CAGR, continues to strengthen its position as a global manufacturing powerhouse. Industrial centers such as Shanghai, Shenzhen, and Guangzhou are deploying advanced bismuth systems to enhance manufacturing efficiency in electronics and pharmaceuticals.

In North America, the United States maintains strong momentum with a 2.9 percent CAGR, driven by sustained investment in industrial innovation and medical manufacturing programs. Mexico, at 3.0 percent CAGR, is leveraging its mining infrastructure and expanding refining capacity to become a critical supply hub. In Europe, Germany continues to lead with a 2.8 percent CAGR, emphasizing precision manufacturing and high-quality refining standards that define the region’s industrial leadership.

The competitive landscape remains moderately concentrated, with around twenty key participants worldwide. Hunan Jinwang, 5N Plus, and Hunan Huaxing together command approximately 30 to 40 percent of global market share, leveraging advanced processing capabilities, high-purity technologies, and strong relationships with manufacturing and pharmaceutical customers. Other notable participants, including AIM Specialty, Met-Mex Peñoles, Merck, Mitsubishi Materials, American Elements, and Shoei Chemical, continue to expand their portfolios through innovation in refining systems, quality control integration, and global partnerships.

Emerging companies in India, China, and Mexico are reshaping competition by introducing localized processing operations and cost-effective solutions, supporting broader accessibility of bismuth for regional manufacturing and pharmaceutical markets. The next phase of competition will increasingly center on purity optimization, process automation, and digital quality assurance, rather than price differentiation alone.

Looking ahead, the bismuth market represents a strategic growth opportunity for industrial manufacturers, investors, and policymakers alike. As industries pivot toward cleaner, more efficient production models, bismuth’s combination of environmental safety, metallurgical precision, and material adaptability will play a defining role in shaping the next generation of industrial and pharmaceutical technologies.

Governments can further accelerate this trajectory by supporting processing infrastructure investments, providing tax incentives for refining technology modernization, and creating harmonized regulatory frameworks that facilitate global trade in specialized bismuth compounds. Industry bodies can also strengthen market confidence through the establishment of processing certification programs, purity benchmarks, and technical training standards for metallurgical and pharmaceutical applications.

With global demand poised to reach USD 1.12 billion by 2035, the bismuth market stands as a testament to industrial evolution. For manufacturers, it represents an opportunity to enhance performance and sustainability simultaneously. For investors, it offers a pathway to long-term, technology-driven value creation. And for the broader industrial community, it marks the beginning of a new era of precision materials that align with the world’s advancing manufacturing and environmental priorities.

Browse Full Report : https://www.factmr.com/report/bismuth-market