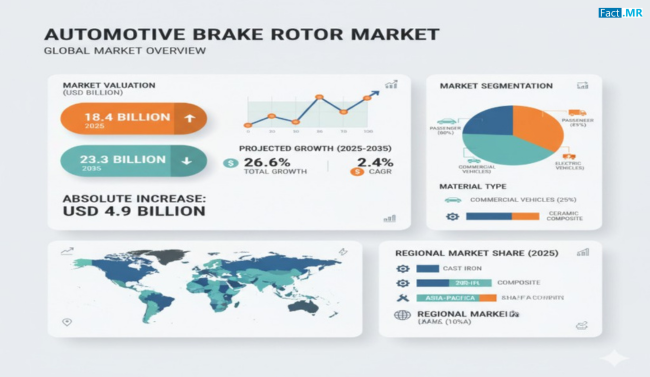

Automotive brake rotors, also known as brake discs, are a critical component in vehicle braking systems, ensuring the safe deceleration and stopping of vehicles. As automotive safety and performance remain top priorities, the brake rotor market is gaining attention for its role in improving vehicle control, durability, and efficiency. The increasing focus on passenger safety, rising vehicle production, and adoption of advanced braking technologies are fueling the growth of this market.

Market Overview:

Brake rotors work by creating friction with brake pads to slow or stop the wheels. They convert a vehicle’s kinetic energy into heat, ensuring effective braking performance. Modern vehicles, including passenger cars, commercial vehicles, and electric vehicles, rely on high-quality brake rotors to maintain safety, comfort, and performance. Brake rotors are made from materials like cast iron, carbon composites, and steel, chosen for their thermal conductivity, wear resistance, and vibration damping properties. The market also includes various types of rotors such as blank & smooth, slotted, drilled, and drilled & slotted, each designed for specific performance requirements and applications.

Key Trends & Developments:

Several trends are shaping the automotive brake rotor market:

- Material Innovation:Cast iron continues to dominate due to its cost-effectiveness, durability, and thermal management properties. However, advanced materials like carbon composites are emerging in high-performance and luxury vehicles.

- Growth of Commercial Vehicles:The rise in commercial vehicle demand for logistics, e-commerce, and passenger transport increases the need for robust brake systems.

- Electric and Hybrid Vehicles:Adoption of regenerative braking in EVs and hybrids is influencing rotor design, although conventional rotors remain essential for safety and durability.

- Aftermarket Demand:As vehicle fleets grow, aftermarket brake rotor replacements and upgrades provide a significant opportunity for manufacturers and suppliers.

- Technological Advancements:Manufacturers are focusing on precision engineering, lightweight designs, and improved heat dissipation to enhance rotor performance and lifespan.

Regional Insights:

- North America:The U.S. market is a key player, supported by high vehicle ownership, advanced manufacturing capabilities, and strict safety standards. Both passenger and commercial vehicle segments contribute to the growing demand for brake rotors.

- Europe:European countries are witnessing growth due to automotive production, luxury car demand, and regulatory compliance for vehicle safety and emissions. Technological innovations and advanced rotor designs are widely adopted.

- Asia-Pacific:Rapid industrialization, urbanization, and rising disposable incomes in countries like China, India, Japan, and South Korea are fueling demand for vehicles, leading to increased adoption of brake rotors. OEMs increasingly source components from this region due to competitive manufacturing capabilities.

- Other Regions:Latin America and the Middle East show gradual growth driven by expanding automotive production, urbanization, and increased awareness of vehicle safety.

Applications & End-Use Outlook:

Brake rotors are applied across various vehicle types and sectors:

- Passenger Vehicles:The majority of demand arises from cars, SUVs, and light trucks, driven by consumer safety preferences and regulatory standards.

- Commercial Vehicles:Heavy-duty trucks, buses, and delivery vehicles require high-performance rotors to handle frequent braking and heavy loads.

- Electric and Hybrid Vehicles:Brake rotors complement regenerative braking systems, providing reliability and enhanced safety during deceleration.

- Aftermarket:Replacement rotors for maintenance, performance upgrades, and vehicle customization represent a significant portion of market revenue.

- High-Performance and Racing Vehicles:Slotted and drilled rotors are increasingly adopted in sports cars for superior heat dissipation and braking efficiency.

Competitive Landscape:

The automotive brake rotor market is competitive, with major players such as Brembo, ADVICS Co., Ltd., Akebono Brake Corporation, Continental AG, Robert Bosch, Valeo SA, EBC Rotor, and Wilwood Engineering leading the industry. Companies focus on R&D to develop durable, lightweight, and heat-resistant rotors. Strategies include collaborations with OEMs, technological innovation, and product diversification to maintain a competitive edge. Start-ups and regional manufacturers also capitalize on niche markets for aftermarket and performance rotors.

Challenges:

The market faces challenges such as raw material price volatility, technological adaptation for EVs, and stringent regulatory compliance. The rise of regenerative braking may reduce conventional rotor usage in certain EV models. Manufacturers must balance cost, performance, and sustainability while delivering reliable products. Safety remains a paramount concern, requiring continuous innovation in rotor design and materials.

Conclusion:

The automotive brake rotor market is essential for vehicle safety, performance, and reliability. With applications spanning passenger vehicles, commercial transport, and electric vehicles, brake rotors ensure controlled deceleration, reduce braking distances, and enhance driver confidence. Growth is driven by rising vehicle production, demand for advanced braking technologies, and aftermarket opportunities. Companies focusing on innovation, durable materials, and compliance with safety and environmental standards are positioned to benefit from the expanding global demand for high-performance automotive brake rotors.

Browse Full Report – https://www.factmr.com/report/3873/automotive-brake-rotors-market