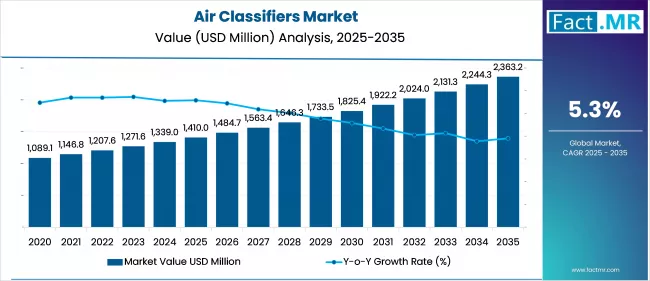

The air classifiers market is expected to witness strong growth over the next decade as industries increasingly prioritise efficient particle separation, precise material classification, and process optimisation across mineral processing, cement, chemicals, pharmaceuticals, food processing, and recycling sectors. In 2025, the market is valued at approximately USD 4.2 billion, and it is projected to reach USD 10.8 billion by 2035, representing an absolute increase of USD 6.6 billion over the forecast period. This expansion corresponds to a compound annual growth rate (CAGR) of around 9.8% between 2025 and 2035, driven by rising demand for high-precision particle separation technologies, growth in advanced materials manufacturing, and emphasis on sustainable processing practices.

Air classifiers are mechanical devices used to separate particles based on size, shape, and density using controlled airflow, centrifugal forces, and aerodynamic principles. They enable producers to achieve uniform particle size distributions essential for product quality, operational efficiency, and material performance in diverse applications.

Quick Market Snapshot (2025–2035)

-

Market Value (2025): USD 4.2 Billion

-

Market Forecast Value (2035): USD 10.8 Billion

-

Forecast CAGR: ~9.8%

-

Primary Classifier Types: Dynamic classifiers, static classifiers

-

Leading End-Use Industries: Mining & Minerals, Cement & Construction, Chemicals & Pharmaceuticals, Food Processing, Recycling

-

Key Growth Regions: Asia Pacific, North America, Europe

To access the complete data tables and in-depth insights, request a Discount On The Report here: https://www.factmr.com/connectus/sample?flag=S&rep_id=3953

Market Overview

Air classifiers are essential components in many industrial material handling and processing systems, particularly where precise particle size control is critical. They are deployed in applications such as mineral powder classification, cement fineness control, chemical powder separation, food ingredient processing, and recycling of fine materials. By enabling separation of particles into desired size fractions, air classifiers help optimise downstream processes, enhance product consistency, reduce energy consumption, and lower waste generation.

Air classifiers are broadly categorised into dynamic classifiers — which use rotating elements and real-time airflow adjustments for precise separation — and static classifiers — which use fixed vanes or aerodynamic paths. Innovations in classifier design, control systems, and integration with automation platforms are improving performance, enabling highly customisable classification outcomes and supporting smart manufacturing initiatives.

Key Demand Drivers

Rising Demand for High-Quality Materials

Industries such as cement, mineral processing, chemicals, and pharmaceuticals require strict control of particle size distributions to meet performance standards. In cement and construction materials, fine particle separation improves strength, hydration rates, and durability. In chemicals and pharmaceuticals, uniform particle size enhances reactivity, solubility, and product consistency. Air classifiers play a pivotal role in achieving these material specifications.

Growth in Mining and Minerals Processing

Mining operations are increasingly adopting air classifiers to improve mineral beneficiation, tailings management, and fine particle recovery. As ore grades decline and processing challenges increase, classifiers help maximise material utilisation, reduce energy costs, and support efficient milling and grinding circuits.

Efficiency and Sustainability Objectives

Air classifiers contribute to energy efficiency by reducing the need for extensive mechanical grinding and screening processes. By producing controlled particle sizes with less energy input, they support sustainability goals and lower operational costs. This aligns with broader industry priorities to improve environmental performance and meet regulatory expectations.

Automation and Digitalisation in Manufacturing

The integration of air classifiers with digital control systems, real-time monitoring, and predictive maintenance tools is enabling smarter, more adaptive classification processes. Manufacturers are investing in Industry 4.0 technologies to improve process visibility, reduce downtime, and enhance throughput. Air classifiers integrated with automation platforms deliver performance gains that are attractive in competitive industrial environments.

Market Segmentation Insights

By Classifier Type

-

Dynamic Air Classifiers: Use adjustable rotating elements and real-time airflow control to deliver precise and flexible classification across material types. They are increasingly adopted in applications demanding high levels of control.

-

Static Air Classifiers: Offer robust, maintenance-friendly separation using fixed aerodynamic paths and vanes; ideal for simpler or less variable material streams.

-

Other Custom and Hybrid Configurations: Tailored solutions that combine features of both static and dynamic designs for specialised industrial requirements.

By Separation Mechanism

-

Centrifugal Separation: Widely used for high-throughput mineral and bulk material processing where density and size differentiation are key.

-

Airflow/Aerodynamic Separation: Common in fine powders, chemical processing, and food ingredients where delicate material handling is required.

By End-Use Industry

-

Mining & Mineral Processing: Major application segment due to extensive use in grinding circuits and beneficiation operations.

-

Cement & Construction: Growing adoption for fineness control and product quality enhancement.

-

Chemical & Pharmaceutical: Particle size precision drives demand for high-performance classifiers.

-

Food Processing: Used for separation of flour, starches, spices, and other powdered food ingredients.

-

Recycling & Waste Management: Enable separation of fine materials and particulates in recycling streams.

-

Other Industrial Sectors: Including fertilizer production, ceramic materials, and speciality powder manufacturing.

Regional Demand Dynamics

Asia Pacific

Asia Pacific is poised to be the fastest-growing regional market through 2035, supported by rapid expansion in industrial production, mining activities, and infrastructure development. Increasing investments in cement production capacity, mineral processing facilities, and advanced manufacturing plants in countries such as China, India, and Southeast Asian economies are driving strong demand for air classifiers.

North America

North America remains a significant market due to advanced industrial processes, widespread adoption of automation, and emphasis on energy efficiency. Robust mining, chemical production, and construction sectors contribute to steady growth, supported by technological innovation and manufacturing excellence.

Europe

Europe exhibits solid demand for air classifiers driven by stringent product quality standards and high levels of industrial modernisation. Automation and digital integration are key trends in Europe, enhancing classifier performance and supporting the region’s competitiveness.

Other Regions

Latin America, the Middle East, and Africa are gradually expanding their use of air classifiers as industrialisation grows. Mining and construction investments — alongside efforts to improve material processing efficiency — support incremental market adoption.

Competitive Landscape

The air classifiers market features a competitive mix of global industrial equipment manufacturers, automation technology companies, and specialised materials handling solution providers. Key strategies among market participants include product innovation focused on improved efficiency and precision, expansion of service and aftermarket support, and integration with digital control systems for smart manufacturing applications.

Manufacturers are also emphasising modular designs, ease of maintenance, and scalability to meet diverse industry needs. Collaborations with end users to develop customised classification solutions are enhancing market responsiveness and adoption across segments.

Future Outlook

The air classifiers market is expected to sustain strong growth through 2035 as demand for efficient material classification, process optimisation, and sustainable operations continues to rise. Advancements in classifier design, digital integration, and process automation will further enhance the performance, versatility, and energy efficiency of air classifier systems.

As industries pursue smarter manufacturing and material processing strategies, air classifiers will play an increasingly important role in improving product quality, reducing operational costs, and enabling greater control over particle size distribution across a broad set of applications.

Browse Full Report: https://www.factmr.com/report/3953/air-classifiers-market