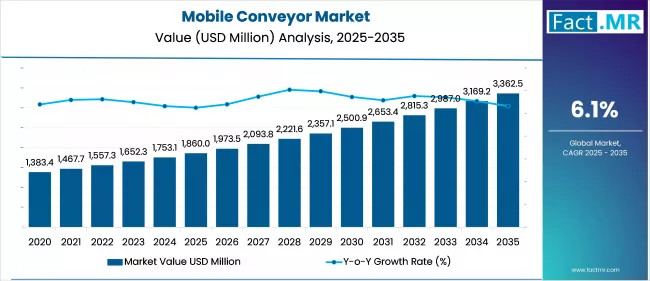

The mobile conveyor market is projected to witness strong growth over the next decade as industries increasingly prioritise efficient material handling, automation, and flexible production lines across mining, construction, manufacturing, logistics, and ports. In 2025, the market is valued at approximately USD 2.4 billion, and it is expected to reach USD 5.9 billion by 2035, representing an absolute increase of USD 3.5 billion over the forecast period. This growth correlates to a compound annual growth rate (CAGR) of around 9.8% between 2025 and 2035, driven by increasing adoption of automated material handling systems, expansion of warehousing infrastructure, and rising demand for mobile, adaptable conveyor solutions in dynamic industrial environments.

Mobile conveyors are versatile material transport systems designed to move goods, bulk materials, and components between different points within industrial facilities, construction sites, and logistics hubs. Their mobility, scalability, and integration with existing operations make them ideal for modern material handling needs.

Quick Market Snapshot (2025–2035)

-

Market Value (2025): USD 2.4 Billion

-

Market Forecast Value (2035): USD 5.9 Billion

-

Forecast CAGR: ~9.8%

-

Leading Conveyor Type: Belt conveyors

-

Key End-Use Industries: Mining & Construction, Warehousing & Logistics, Manufacturing, Ports & Terminals

-

Primary Growth Regions: North America, Europe, Asia Pacific

To access the complete data tables and in-depth insights, request a Discount On The Report here: https://www.factmr.com/connectus/sample?flag=S&rep_id=3941

Market Overview

Mobile conveyors are engineered to enhance material flow efficiency across short- and long-distance movements in industrial settings. Unlike fixed conveyors, mobile units can be repositioned, reconfigured, and deployed rapidly to meet changing operational requirements. They include systems such as wheeled conveyors, tracked conveyors, portable belt conveyors, and modular mobile systems that support tasks like loading, unloading, stockpiling, and feed-line operations.

Integration with automation technologies such as programmable logic controllers (PLCs), remote controls, and conveyor monitoring systems further enhances operational efficiency, safety, and throughput. In high-velocity industries — such as e-commerce warehousing — mobile conveyors support rapid fulfilment cycles, reduce manual handling, and contribute to lean supply chain operations.

Key Demand Drivers

Expansion of Warehousing and Logistics Infrastructure

The ongoing expansion of warehousing and logistics operations — particularly driven by e-commerce growth — is a major driver for mobile conveyor adoption. Logistics facilities demand flexible, scalable conveyor systems that can adapt to fluctuating inventory levels, seasonal peaks, and multi-product handling requirements. Mobile conveyors support dynamic layout changes, cross-docking, and rapid deployment in logistics environments.

Automation and Industry 4.0 Integration

Industries are increasingly adopting automation and smart manufacturing solutions to optimise productivity and reduce labour costs. Mobile conveyors, when integrated with automation technologies, support real-time monitoring, predictive maintenance, and seamless operation with automated guided vehicles (AGVs) and robotic picking systems. This convergence of material handling and digital systems is a significant driver for market growth.

Mining, Construction, and Bulk Material Handling

In mining and construction sectors, mobile conveyors enable efficient bulk material movement across rugged and changing terrain. They are used for overburden removal, material stockpiling, and feed line transport to crushers and processing plants. Port terminals also utilise mobile conveyor systems for efficient cargo handling, especially in containerised and bulk operations.

Need for Operational Flexibility

Mobile conveyors deliver flexibility that fixed systems cannot match. Facilities undergoing frequent reconfiguration — such as manufacturing lines that adapt to seasonal product variations — benefit from conveyors that can be moved or reoriented quickly. This flexibility is increasingly valued in industries facing rapid technological change and shifting demand.

Market Segmentation Insights

By Conveyor Type

-

Belt Conveyors: The largest segment, widely adopted due to high throughput, ease of operation, and suitability for bulk and unit loads.

-

Roller Conveyors: Used for handling packaged goods and pallets; often integrated into warehouse conveyor networks.

-

Chain Conveyors: Preferred in heavy-duty applications for robust material transport.

-

Telescopic & Extendable Conveyors: Growing demand in logistics for rapid truck loading/unloading.

-

Modular & Other Variants: Customised mobile conveyor configurations for specialised operations.

By Material Type

-

Bulk Materials: Includes aggregates, ores, coal, and minerals predominantly in mining, construction, and port operations.

-

Unit Loads & Packaged Goods: Key segment for warehousing, parcel handling, manufacturing, and distribution centres.

-

Palletised Loads: Segment where robust mobile conveyors support pallet movement between areas.

By End User Industry

-

Warehousing & Logistics: The fastest growing segment due to e-commerce and omnichannel fulfilment pressures.

-

Mining & Construction: Significant share driven by bulk material handling and site mobility needs.

-

Manufacturing: Mobile conveyors support assembly lines, part delivery, and integrated material flows.

-

Ports & Terminals: Used for efficient cargo movement and container handling.

-

Retail & Distribution: Adoption grows with store back-of-house automation and cross-dock operations.

Regional Demand Dynamics

North America

North America is a leading market due to advanced logistics infrastructure, widespread adoption of warehouse automation, and strong presence of manufacturing facilities. The region’s robust e-commerce growth and investments in material handling technologies support continuous mobile conveyor adoption.

Europe

Europe shows steady market expansion driven by manufacturing innovation, automation investments, and sustainability initiatives that promote efficient operations. Countries in Western Europe, in particular, demand mobile conveyors in automotive and consumer goods sectors.

Asia Pacific

Asia Pacific is projected to register rapid growth through 2035. Expanding industrial activity, infrastructure projects, and burgeoning logistics networks in China, India, Southeast Asia, and Japan are significant contributors. Regional investment in smart manufacturing and urban logistics further accelerates demand.

Rest of World

Latin America, the Middle East, and Africa are gradually increasing mobile conveyor adoption as industrial development and supply chain modernisation progress. Infrastructure upgrades and mining expansion in these regions support emerging growth opportunities.

Competitive Landscape

The mobile conveyor market is moderately competitive, featuring global material handling solution providers, industrial automation firms, and specialised conveyor manufacturers. Key strategies employed by market participants include product innovation, expansion of modular conveyor portfolios, after-sales service enhancements, and integration with automation platforms.

Manufacturers are focusing on developing mobile conveyors with improved energy efficiency, easy deployment mechanisms, advanced control interfaces, and enhanced safety features. Partnerships with logistics integrators and industrial automation suppliers are strengthening market reach and adoption rates.

Future Outlook

The mobile conveyor market is anticipated to sustain strong growth through 2035 as industries continue to automate, modernise, and pursue flexible material handling solutions. Technological advancements such as IoT-enabled conveyor monitoring, predictive maintenance systems, and collaborative robotics integration are expected to further enhance operational efficiency and drive market expansion.

As global supply chains evolve toward higher throughput, agility, and automation, mobile conveyor systems will play a central role in enabling efficient, responsive, and resilient material handling across diverse industrial sectors.

Browse Full Report: https://www.factmr.com/report/3941/mobile-conveyor-market