Vinyl flooring plasticizers are essential additives that enhance the flexibility, durability, and overall performance of vinyl flooring products. In the UK, these plasticizers are increasingly integrated into residential, commercial, and industrial flooring applications to meet evolving construction standards, aesthetic demands, and environmental regulations. Their adoption reflects the construction sector’s focus on sustainable, high-performance materials that deliver long-term value.

Market Overview:

Vinyl flooring plasticizers improve the softness, resilience, and processability of PVC-based flooring materials. They are vital for ensuring durability, low volatility, migration resistance, and compliance with indoor air quality standards. Advanced formulations, including DINP/DIDP, DOTP, and bio-based varieties, offer optimized chemical properties that cater to residential, commercial, and industrial flooring needs. The UK market emphasizes both performance and regulatory compliance, driving demand for innovative plasticizer technologies that align with modern construction practices.

Regional Insights:

England serves as the primary hub for vinyl flooring plasticizer demand and innovation, supported by a strong construction sector and sophisticated manufacturing infrastructure. Scotland, Wales, and Northern Ireland are also significant contributors, particularly in commercial and residential construction projects. Across the UK, increasing home renovation projects, modern housing developments, and commercial construction initiatives are key drivers for the adoption of specialized plasticizers.

Key Trends & Forecast:

- Residential Flooring Dominance:

Residential flooring accounts for a significant share of plasticizer demand due to its high-volume applications in homes, apartments, and urban development projects. Plasticizers enhance the flexibility and comfort of vinyl flooring while ensuring long-term durability. - Advanced Plasticizer Technologies:

DINP/DIDP formulations are widely used for their performance reliability and cost-effectiveness. Innovations in DOTP and bio-based plasticizers are also gaining attention due to environmental concerns and sustainability trends in the construction industry. - Sustainability and Environmental Compliance:

Manufacturers are increasingly focusing on eco-friendly and non-phthalate plasticizers that comply with REACH regulations and ISO standards. Adoption of sustainable solutions is crucial for maintaining indoor air quality and reducing environmental impact. - Construction and Renovation Growth:

Rising construction activities and renovation projects across residential and commercial sectors drive demand for high-performance plasticizers. Modern flooring solutions rely on plasticizers for flexibility, installation ease, and long-lasting performance. - Integration of Performance and Aesthetic Features:

Beyond flexibility, plasticizers enhance the visual appeal of vinyl flooring through compatibility with luxury vinyl tiles and sheets. This integration ensures that performance additives do not compromise color stability, texture, or surface quality.

Applications & End-Use Outlook:

Residential flooring is the leading end-use segment, followed by commercial and industrial applications. Vinyl flooring plasticizers are critical for luxury vinyl tiles, sheet flooring, and other high-end residential installations. In commercial and industrial projects, plasticizers contribute to durability, wear resistance, and safety performance, supporting long-term construction goals and cost efficiency.

Industry Drivers:

The UK vinyl flooring plasticizers market is fueled by growing construction activity, increasing demand for sustainable materials, and emphasis on high-performance flooring solutions. Manufacturers are adopting advanced additive technologies to ensure consistent performance, compliance with environmental regulations, and enhanced product reliability. Demand for DINP/DIDP and bio-based solutions is further strengthened by the need for cost-effective, eco-friendly chemical solutions.

Competitive Landscape:

Key players in the UK market include global chemical manufacturers and specialty plasticizer producers. Companies focus on innovation, production scalability, and regulatory compliance to maintain a competitive edge. Strategic investments in research, sustainable technologies, and technical support for flooring manufacturers are enabling market players to strengthen their presence and expand adoption across residential, commercial, and industrial sectors.

Conclusion:

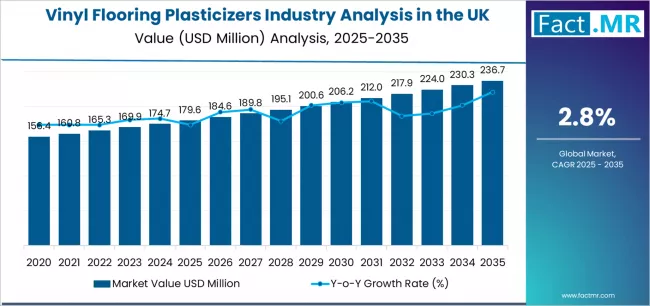

The vinyl flooring plasticizers industry in the UK is poised for steady growth, driven by the convergence of construction expansion, sustainability requirements, and advanced additive technologies. Residential flooring remains the largest end-use segment, while commercial and industrial applications continue to support market expansion. As manufacturers invest in high-performance, eco-friendly plasticizers, the UK flooring industry will continue to benefit from improved durability, flexibility, and compliance with modern construction standards.

Browse Full Report – https://www.factmr.com/report/united-kingdom-vinyl-flooring-plasticizers-industry-analysis