The sustainable anti-foam agents for wastewater and biogas plants market is gaining increasing importance as water treatment facilities and renewable energy producers focus on operational efficiency and environmental responsibility. Foam formation is a common challenge in wastewater treatment processes and biogas production systems, where excessive foaming can disrupt operations, reduce processing efficiency, and lead to equipment damage.

Traditional anti-foam agents have been effective in controlling foam, but concerns related to toxicity, biodegradability, and long-term environmental impact have encouraged the shift toward sustainable alternatives. Sustainable anti-foam agents are designed to deliver effective foam control while minimizing ecological footprint, making them a critical component in modern wastewater and biogas plant operations.

Market Overview

Sustainable anti-foam agents are specialty chemicals formulated to suppress or prevent foam formation in aqueous systems. In wastewater treatment plants and biogas facilities, these agents help maintain stable processing conditions, improve gas yield, and prevent overflow or system shutdowns.

The market is shaped by the increasing adoption of sustainable water management practices, stricter environmental regulations, and the expansion of biogas plants as part of global renewable energy initiatives. Plant operators are prioritizing eco-friendly solutions that support process efficiency without compromising environmental compliance.

Key Market Drivers

Growing Focus on Environmental Sustainability

Environmental sustainability is a central driver of demand for sustainable anti-foam agents. Wastewater treatment facilities and biogas plants are under pressure to reduce chemical emissions and adopt biodegradable and non-toxic additives that align with environmental standards.

Expansion of Wastewater Treatment Infrastructure

Rapid urbanization and industrialization are driving the expansion of wastewater treatment infrastructure worldwide. Increased treatment capacity has intensified the need for effective foam control solutions that are safe for long-term use.

Rising Adoption of Biogas as Renewable Energy

Biogas plants play a vital role in waste-to-energy initiatives. Foam formation during anaerobic digestion can reduce gas production efficiency, making sustainable anti-foam agents essential for stable and continuous operations.

Regulatory Compliance and Safety Requirements

Stricter regulations governing chemical usage in water treatment and renewable energy facilities are accelerating the transition toward sustainable anti-foam agents that meet safety and environmental compliance standards.

Product Type Insights

Silicone-Based Sustainable Anti-Foam Agents

Silicone-based formulations are widely used due to their strong foam suppression capabilities and stability under varying process conditions. Sustainable variants are engineered to reduce environmental persistence while maintaining high performance.

Bio-Based Anti-Foam Agents

Bio-based anti-foam agents derived from renewable resources are gaining traction. These products offer biodegradability and lower toxicity, making them suitable for environmentally sensitive applications.

Oil-Based Anti-Foam Agents

Oil-based sustainable anti-foam agents provide effective foam control in anaerobic digestion and sludge processing. Formulations are being optimized to reduce environmental impact and improve compatibility with biological systems.

Water-Based Anti-Foam Solutions

Water-based anti-foam agents are preferred in applications requiring easy dispersion and minimal residue. These solutions are commonly used in secondary and tertiary wastewater treatment stages.

Application Outlook

Municipal Wastewater Treatment Plants

Foam formation during aeration and biological treatment stages can hinder process efficiency. Sustainable anti-foam agents help maintain stable operations while supporting environmental objectives.

Industrial Wastewater Treatment

Industries such as food processing, chemicals, and pulp and paper generate wastewater prone to foaming. Eco-friendly anti-foam agents enable effective treatment while meeting discharge regulations.

Anaerobic Digesters in Biogas Plants

Foam control is critical in anaerobic digestion to prevent gas flow disruption and system downtime. Sustainable anti-foam agents improve biogas yield and plant reliability.

Sludge Treatment and Handling

During sludge thickening, digestion, and dewatering, foam can affect processing efficiency. Sustainable anti-foam agents support smoother operations and improved throughput.

End-Use Industry Analysis

Municipal Utilities

Municipal utilities are key end users due to increasing wastewater treatment demands and the need for environmentally compliant chemical solutions.

Renewable Energy Producers

Biogas plant operators rely on sustainable anti-foam agents to enhance process stability and support renewable energy generation goals.

Industrial Processing Facilities

Manufacturing and processing industries benefit from sustainable foam control solutions that reduce operational disruptions and environmental impact.

Agricultural and Organic Waste Facilities

Facilities processing organic waste for biogas production or composting require eco-friendly anti-foam agents to maintain biological process efficiency.

Regional Insights

North America

North America demonstrates strong adoption of sustainable anti-foam agents due to advanced wastewater treatment infrastructure and stringent environmental regulations.

Europe

Europe leads in sustainability initiatives and circular economy practices. The region’s focus on renewable energy and water reuse supports market growth.

Asia-Pacific

Rapid urbanization, expanding wastewater treatment capacity, and growing investments in biogas projects are driving demand across Asia-Pacific.

Latin America and Middle East & Africa

These regions are experiencing gradual adoption, supported by infrastructure development and increasing awareness of sustainable water and energy solutions.

Technological Advancements

Innovation in formulation chemistry is enhancing the performance and environmental profile of sustainable anti-foam agents. Manufacturers are developing products with improved dispersion, longer-lasting foam control, and reduced dosage requirements.

Advances in bio-based materials and green chemistry are enabling the development of anti-foam agents that are compatible with biological treatment processes. Integration with automated dosing systems is further improving operational efficiency.

Competitive Landscape

The market features a mix of global chemical suppliers and specialized solution providers focused on water treatment and renewable energy applications. Competition is driven by product performance, sustainability credentials, and technical support capabilities.

Companies are investing in research and development to expand their sustainable product portfolios and address specific challenges faced by wastewater and biogas plants. Strategic partnerships with plant operators and engineering firms are common to deliver customized solutions.

Challenges and Market Constraints

Despite growing adoption, sustainable anti-foam agents face challenges such as higher upfront costs compared to conventional products and varying performance requirements across different treatment systems. Selecting the right formulation often requires process-specific testing and optimization.

Limited awareness in certain regions and operational resistance to changing established chemical practices can also slow adoption.

Future Outlook

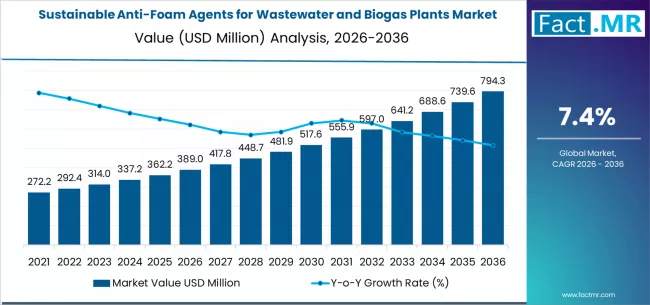

The sustainable anti-foam agents for wastewater and biogas plants market is expected to continue evolving as environmental regulations tighten and sustainability goals gain prominence. Demand will be driven by the expansion of wastewater treatment infrastructure, growth in biogas production, and increasing emphasis on eco-friendly chemical solutions.

Opportunities exist in emerging markets, plant upgrades, and integration with smart process control systems. Manufacturers that focus on innovation, regulatory compliance, and environmental performance are well positioned for long-term success.

Conclusion

Sustainable anti-foam agents play a crucial role in maintaining efficient and environmentally responsible operations in wastewater treatment and biogas plants. By delivering effective foam control with reduced ecological impact, these solutions support both operational reliability and sustainability objectives.

Access to in-depth market insights and industry analysis can help stakeholders navigate regulatory requirements, technological advancements, and competitive dynamics. As the global focus on water management and renewable energy intensifies, sustainable anti-foam agents will remain an essential component of modern treatment and energy systems.

Browse Full Report – https://www.factmr.com/report/sustainable-anti-foam-agents-for-wastewater-and-biogas-plants-market