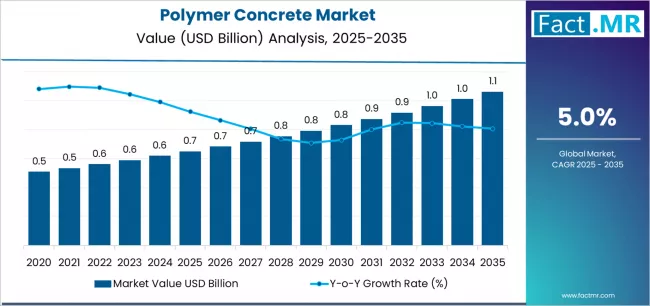

The market for polymer concrete is expected to develop by an astounding USD 0.41 billion throughout the forecast period, from USD 0.65 billion in 2025 to roughly USD 1.06 billion by 2035.

Polymer concrete is a composite material formed by binding aggregates such as sand, gravel, or crushed stone with polymer resins instead of traditional cement. Known for its high mechanical strength, chemical resistance, rapid curing time, and durability, polymer concrete is widely used in infrastructure, industrial flooring, drainage systems, and repair applications.

The global polymer concrete market is witnessing steady growth as construction activities increase across infrastructure, industrial, and commercial sectors. Rising demand for corrosion-resistant and long-lasting construction materials is driving adoption across developed and emerging economies alike.

Quick Market Snapshot (2025–2035)

-

Market Growth Outlook: Moderate to strong growth trajectory

-

Key End-Use Sectors: Infrastructure, industrial construction, utilities

-

Leading Resin Type: Polyester resin-based polymer concrete

-

Fastest-Growing Application: Drainage systems and repair works

-

Primary Growth Regions: North America, Europe, Asia Pacific

To access the complete data tables and in-depth insights, request a Discount On The Report here: https://www.factmr.com/connectus/sample?flag=S&rep_id=12531

Market Overview

Polymer concrete offers superior performance compared to conventional cement concrete, especially in environments exposed to chemicals, moisture, and extreme temperatures. Its low permeability, high compressive strength, and excellent bonding properties make it suitable for specialized construction applications where durability is critical.

The market is benefiting from increased investments in infrastructure modernization, wastewater management systems, and industrial facilities. Polymer concrete is also gaining traction in precast applications due to its fast curing time and ability to be molded into complex shapes.

Key Drivers Fueling Market Growth

1. Rising Infrastructure Development

Government spending on infrastructure projects such as bridges, tunnels, roads, and drainage networks is increasing demand for high-performance construction materials like polymer concrete.

-

Use in manholes, trench drains, and sewer systems

-

Preferred for long service life and minimal maintenance

-

Effective in aggressive environmental conditions

2. Demand for Corrosion-Resistant Materials

Polymer concrete exhibits excellent resistance to chemicals, acids, salts, and oils, making it ideal for industrial environments.

-

Widely used in chemical plants and refineries

-

Suitable for wastewater treatment facilities

-

Reduced degradation compared to cement-based concrete

3. Growth in Repair & Rehabilitation Projects

Aging infrastructure across developed regions is driving demand for fast-setting and durable repair materials.

-

Rapid curing reduces downtime

-

Strong adhesion to existing substrates

-

Long-term structural performance

4. Expansion of Industrial Flooring Applications

Industrial facilities require flooring solutions that can withstand heavy loads and chemical exposure.

-

High compressive and flexural strength

-

Smooth, seamless finish

-

Long lifecycle with low maintenance

Market Segmentation Analysis

By Resin Type

-

Polyester Resin:

Most widely used due to cost-effectiveness and balanced performance properties. -

Epoxy Resin:

Preferred for high-strength and high-temperature applications. -

Vinyl Ester Resin:

Used where superior chemical resistance is required.

By Application

-

Drainage Systems:

Largest application segment, including channels, grates, and trench drains. -

Industrial Flooring:

Used in manufacturing plants, warehouses, and processing units. -

Structural Components:

Beams, panels, and precast elements for specialized construction. -

Repair & Maintenance:

Crack filling, resurfacing, and structural rehabilitation.

By End-Use Industry

-

Infrastructure & Construction:

Roads, bridges, tunnels, and public utilities. -

Industrial Facilities:

Chemical plants, power stations, and factories. -

Municipal Applications:

Sewage systems, stormwater management, and manholes. -

Commercial Buildings:

Parking structures and service areas.

Key Challenges in the Market

1. Higher Material Cost

Polymer concrete is more expensive than traditional concrete, limiting its use in cost-sensitive projects.

2. Limited Awareness in Emerging Markets

Lack of technical knowledge and skilled labor can slow adoption in developing regions.

3. Handling & Installation Complexity

Precise formulation and mixing are required to achieve optimal performance.

4. Environmental Concerns

Use of synthetic resins raises concerns regarding sustainability and recyclability.

Growth Opportunities

1. Infrastructure Modernization Programs

Upgrading aging drainage and utility systems presents strong growth potential.

2. Adoption in Precast Construction

Fast curing and moldability make polymer concrete ideal for precast components.

3. Technological Advancements in Resin Formulations

Development of low-emission and bio-based resins can enhance sustainability.

4. Expansion in Asia Pacific

Rapid urbanization and industrialization are creating new demand pockets.

Competitive Landscape Insights

Market participants focus on:

-

Product innovation and customized formulations

-

Expansion of manufacturing capacity

-

Strategic partnerships with construction firms

-

Development of application-specific polymer concrete solutions

Quality consistency, performance reliability, and technical support play a critical role in supplier selection.

Future Outlook (2025–2035)

The polymer concrete market is expected to grow steadily over the next decade, supported by infrastructure investments, industrial expansion, and rising demand for durable construction materials. Drainage systems and industrial applications will remain dominant, while repair and rehabilitation projects will generate consistent demand.

Manufacturers that invest in sustainable resin technologies, cost optimization, and application-specific solutions are likely to gain a competitive edge. As construction standards evolve toward long-lasting and high-performance materials, polymer concrete is positioned as a valuable solution in modern construction and infrastructure development.

Browse Full Report: https://www.factmr.com/report/polymer-concrete-market