The polyester hot melt adhesives market is witnessing significant growth as industries increasingly adopt advanced bonding technologies to enhance manufacturing efficiency and product durability. Polyester hot melt adhesives, known for their excellent thermal resistance, strong bonding capabilities, and compatibility with diverse substrates, have become essential in textile, packaging, automotive, and industrial applications. Their ability to provide reliable, washable, and heat-resistant bonds is driving adoption across global industrial operations.

Market Overview:

Polyester hot melt adhesives are thermoplastic adhesives that solidify upon cooling, forming robust bonds suitable for various applications. They are widely utilized in textiles and fabrics, flexible packaging, automotive interiors, and industrial manufacturing processes. The adhesives provide benefits such as high bond strength, resistance to chemicals and heat, and compatibility with modern production equipment. With growing emphasis on sustainability and operational efficiency, polyester hot melt adhesives are increasingly preferred over traditional bonding solutions for applications requiring durability, precision, and environmental compliance.

Key Segments:

The market is primarily segmented by application, with textiles and fabrics dominating due to the rising demand for technical textiles and lamination processes. Advanced polyester adhesives enable superior washability, enhanced thermal stability, and reliable substrate compatibility, making them critical in modern textile manufacturing. Packaging represents the fastest-growing segment, driven by flexible film lamination, paper-based packaging, and the expanding e-commerce sector. Automotive interiors also contribute to market growth, as polyester adhesives facilitate precise bonding of materials requiring thermal resistance and durability. Industrial applications such as composite bonding and product assembly further expand the market potential.

Regional Insights:

Asia-Pacific is emerging as the key growth region for polyester hot melt adhesives, led by China and India. Rapid expansion of textile manufacturing, packaging industries, and industrial production hubs in these countries is driving demand. North America and Europe maintain substantial market shares, supported by mature industrial infrastructure, stringent environmental regulations, and adoption of sustainable manufacturing practices. Emerging markets in Latin America, the Middle East, and Africa are gradually increasing adoption, driven by industrial modernization and the need for high-performance adhesive solutions. The regional growth dynamics demonstrate the global reliance on polyester hot melt adhesives for efficient manufacturing and sustainable operations.

Key Trends & Drivers:

Several trends are shaping the polyester hot melt adhesives market. Industrial manufacturers are prioritizing adhesives that balance performance, cost-effectiveness, and environmental compliance. Technological innovations, including co-polyester formulations, reactive polyester systems, and low-application-temperature adhesives, are expanding product capabilities and enabling more efficient lamination and bonding processes. The demand for sustainable packaging solutions and washable textile bonding further drives adoption. Automated dispensing systems and precision application equipment improve bond consistency and production efficiency, particularly in high-speed textile and packaging operations.

The market is also fueled by increasing emphasis on advanced adhesive infrastructure, allowing manufacturers to integrate polyester hot melt adhesives into complex manufacturing workflows. Focus on thermal resistance, chemical stability, and substrate compatibility ensures that these adhesives meet stringent industrial and consumer product requirements.

Challenges & Market Barriers:

Despite the advantages, challenges exist for the polyester hot melt adhesives market. High-performance formulations and advanced application equipment may require significant initial investment, which could deter cost-sensitive manufacturers. Adherence to environmental and regulatory standards necessitates specialized formulations and compliance testing. Additionally, the complexity of industrial bonding requirements, including high-speed production and multi-material lamination, demands technical expertise and process optimization. Companies must address these challenges to maintain consistent product quality and operational efficiency.

Applications & End-Use Outlook:

Textiles and fabrics represent the leading application, driven by lamination, bonding of technical fabrics, and integration into wearable and industrial textiles. Packaging applications are rapidly growing due to the increasing e-commerce sector, demand for flexible packaging, and adoption of sustainable material requirements. Automotive interiors utilize polyester hot melt adhesives for dashboard assembly, upholstery, and thermal-resistant bonding. Industrial and consumer products manufacturing further benefits from the precision, durability, and adaptability of these adhesives. Across all applications, manufacturers prioritize adhesives that deliver consistent performance, ease of application, and compliance with environmental standards.

Future Outlook:

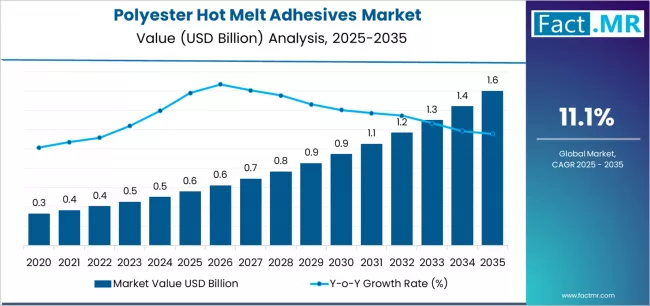

The polyester hot melt adhesives market is poised for continued growth as industries focus on manufacturing efficiency, durability, and sustainability. Technological advancements in adhesive formulations, including co-polyester blends and reactive systems, will expand adoption across textiles, packaging, and automotive applications. Growth in Asia-Pacific manufacturing hubs and expansion in e-commerce packaging solutions will further drive demand. Manufacturers offering tailored solutions, automation integration, and high-performance adhesives will hold a competitive edge.

Conclusion:

Polyester hot melt adhesives are transforming industrial bonding practices by providing high-performance, durable, and environmentally compliant solutions. Their applications across textiles, packaging, automotive, and industrial sectors underscore their versatility and strategic importance. With ongoing technological innovation, increasing adoption of sustainable manufacturing practices, and expanding global industrial infrastructure, the polyester hot melt adhesives market is set to drive efficiency, reliability, and sustainability in modern manufacturing operations worldwide.

Browse Full Report – https://www.factmr.com/report/polyester-hot-melt-adhesives-market