Polyacrylonitrile (PAN) fiber, a high-performance synthetic polymer, has become a cornerstone in modern manufacturing due to its exceptional strength, chemical resistance, and thermal stability. Serving as the primary precursor for carbon fiber production, Polyacrylonitrile fibers are crucial in industries ranging from aerospace and automotive to construction and protective clothing. Their growing adoption underscores the importance of high-performance materials in advancing industrial capabilities and sustainable technologies.

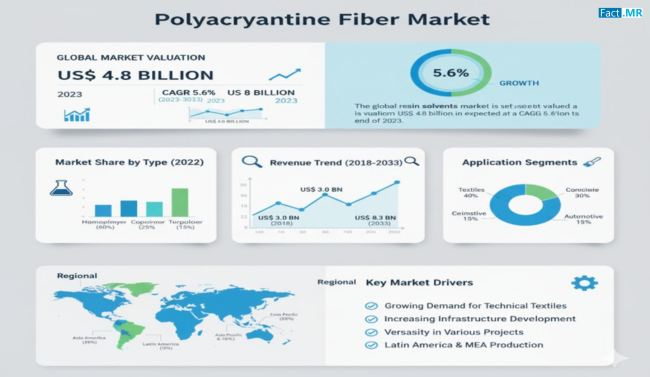

Market Overview:

PAN fibers are produced from the polymerization of acrylonitrile monomers and are known for their durability, dimensional stability, and high carbon yield. Beyond carbon fiber production, they are also used in textiles, filtration systems, and reinforced composite materials. Their versatility allows manufacturers to produce lightweight, high-strength components while maintaining excellent chemical and heat resistance, making PAN fibers integral to next-generation industrial solutions.

Regional Insights:

Asia Pacific, particularly China, is a major consumer of PAN fibers due to the rapid expansion of carbon fiber production, driven by wind energy, aerospace, and infrastructure projects. North America, led by the United States, is another prominent market due to the thriving aerospace sector, which relies heavily on high-quality carbon fibers. Europe also maintains a strong presence, focusing on advanced composites for automotive and industrial applications.

Key Trends & Forecast:

- Growth in Carbon Fiber Production:PAN fibers are the predominant feedstock for carbon fiber, which is increasingly used in aerospace, automotive, and wind energy industries due to its lightweight and high-strength properties.

- Rise in Protective Clothing Applications:PAN fibers’ heat resistance and durability make them ideal for fire-resistant and protective clothing, expanding their usage across safety-focused sectors.

- Technological Advancements in Fiber Production:Manufacturers are investing in wet and dry spinning techniques, as well as innovative fiber modifications, to enhance mechanical properties and cost-efficiency.

- Sustainable Material Focus:As industries prioritize sustainability, PAN fibers are being incorporated into composite solutions that reduce weight, improve fuel efficiency, and lower carbon emissions.

Applications & End-Use Outlook:

PAN fibers have broad applications across multiple industries:

- Carbon Fiber Production:The largest application, used in aerospace, automotive, wind energy, and high-performance sporting goods.

- Textiles & Protective Gear:Fibers are used in fire-resistant garments, industrial uniforms, and specialty clothing.

- Filtration & Composites:PAN fibers are employed in filters for gas and liquids, as well as composite materials for construction and industrial equipment.

- Advanced Manufacturing:Utilized in 3D printing, reinforced plastics, and lightweight structural components.

Challenges:

The high cost of PAN fibers remains a key challenge, as it contributes significantly to the overall cost of carbon fiber production. Additionally, alternative materials such as polyethylene are emerging as lower-cost options with comparable carbon content, posing competitive pressures. Manufacturers must balance cost, performance, and production efficiency to maintain market growth.

Conclusion:

Polyacrylonitrile fibers are vital for modern industries seeking lightweight, durable, and high-strength materials. Their role as a precursor for carbon fiber and their versatility in protective clothing, composites, and advanced manufacturing ensures they remain indispensable in industrial innovation. With increasing investment in R&D and rising demand across aerospace, automotive, and renewable energy sectors, PAN fibers are set to continue shaping the future of high-performance materials globally.

Browse Full Report – https://www.factmr.com/report/polyacrylonitrile-fiber-market