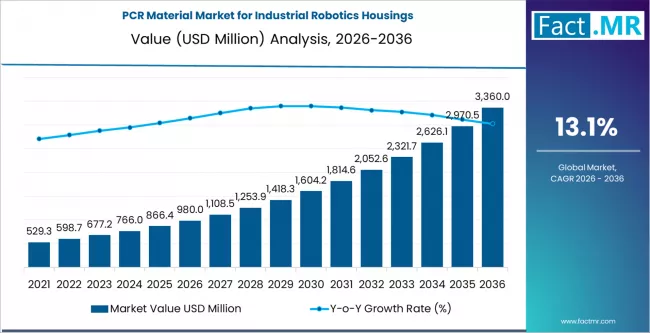

The global market for Post-Consumer Recycled (PCR) materials used in industrial robotics housings is entering a high-growth phase, with its valuation projected to grow from USD 420 million in 2026 to USD 1.25 billion by 2036. According to specialized industry analysis, the market is set to expand at an impressive compound annual growth rate (CAGR) of 11.5%, driven by the convergence of industrial automation and aggressive corporate sustainability mandates.

As the robotics industry scales to meet global labor shortages, the environmental footprint of robot manufacturing has come under scrutiny.1 Industrial robotics housings—traditionally made from virgin engineering plastics—are being redesigned to incorporate PCR resins. This shift allows OEMs (Original Equipment Manufacturers) to reduce the “embodied carbon” of their products while maintaining the durability and chemical resistance required for harsh factory environments.

Summary Table: PCR Materials for Robotics Housings Outlook

| Metric | Details |

| Market Value (2026E) | USD 420 Million |

| Forecast Value (2036F) | USD 1.25 Billion |

| Projected CAGR (2026-2036) | 11.5% |

| Leading Material | PCR Polycarbonate / ABS (40.2% Share) |

| Primary Driver | Collaborative Robots (Cobots) |

| Highest Growth Market | India (13.8% CAGR) |

Request for Sample Report | Customize Report – https://www.factmr.com/connectus/sample?flag=S&rep_id=13646

Core Market Dynamics: Answering the Strategic ‘How’ and ‘Why’

PCR materials for robotics housings primarily involve high-performance recycled resins such as Polycarbonate (PC), Acrylonitrile Butadiene Styrene (ABS), and Polyamide (Nylon) that are reinforced to meet industrial specifications.

-

Who is leading the sector? Industry leaders including SABIC, Covestro AG, BASF SE, Solvay, and Lanxess are at the forefront, developing “Upcycled” engineering-grade PCR blends that offer mechanical properties nearly identical to virgin materials.

-

What is the dominant material? PCR Polycarbonate (PC) and PC/ABS Blends command a leading 40.2% market share. These materials are favored for their high impact resistance and flame-retardant properties, which are essential for protecting the sensitive electronics and sensors within a robot’s chassis.

-

Where is growth most accelerated? India is emerging as a global growth leader with a 13.8% CAGR, fueled by the “Make in India” initiative and a rapid increase in domestic robotics assembly. China follows with a 13.1% CAGR, supported by its status as the world’s largest market for industrial automation.

-

Why is the technology shifting? The market is moving toward Reinforced PCR Composites. By incorporating recycled carbon fiber or glass fiber into PCR resins, manufacturers can produce lightweight housings that improve the energy efficiency of robotic arm movements without compromising structural integrity.

Sector Insights: Collaborative Robots (Cobots) Drive Adoption

The Collaborative Robots (Cobots) segment is seeing the fastest adoption of PCR materials. Unlike heavy, stationary industrial robots, cobots are often designed with lighter, more aesthetic housings. Manufacturers in this space are using PCR content as a key differentiator to appeal to tech-forward customers who prioritize sustainable supply chains.

“Robotics is no longer just about efficiency; it’s about responsibility,” the analysis states. “We are seeing a major trend toward ‘Circular Robotics.’ Leading OEMs are implementing buy-back programs to reclaim old robot housings, which are then processed back into high-purity PCR pellets for new production lines. This ‘cradle-to-cradle’ approach is becoming a competitive necessity in the European and North American markets.”

Key Market Trends and Strategic Outlook

1. Optimization through UV-Stabilized PCR Grades

A significant absolute dollar opportunity lies in UV-Stabilized and Chemical-Resistant PCR. Industrial robots often operate in environments exposed to sunlight, lubricants, and cleaning agents. Specialized PCR blends that resist yellowing and cracking are seeing high demand for outdoor and cleanroom robotics applications.

2. The Rise of 3D-Printed PCR Housings

Innovation is currently focused on Additive Manufacturing. Using PCR-based filaments for 3D printing allows for the rapid prototyping and small-batch production of customized robot housings, significantly reducing material waste compared to traditional injection molding.

3. Regulatory and “Green Procurement” Tailwinds

In the European Union (10.8% CAGR) and the United States (10.2% CAGR), growth is supported by “Green Public Procurement” policies. Governments and large corporations are increasingly requiring that the equipment used in their facilities meets specific recycled-content thresholds, making PCR housings a prerequisite for winning large-scale automation contracts.

Investment Perspective: A High-Growth Industrial Sustainability Niche

The PCR material market for industrial robotics housings represents a robust opportunity for specialty chemical and material science firms. As the global installed base of robots continues to expand and “Sustainability Reporting” becomes mandatory for publicly traded companies, the demand for high-performance, recycled-content housings is expected to remain a primary growth engine through 2036.

Browse Full Report: https://www.factmr.com/report/pcr-material-market-for-industrial-robotics-housings