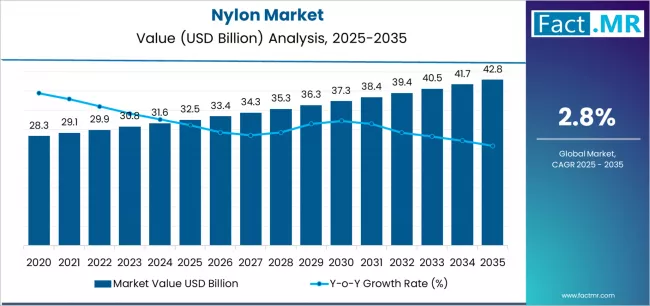

The global nylon market is entering a decade of steady and transformative expansion, driven by rising demand for lightweight materials, high-performance engineering plastics, and sustainable polymer innovations. According to a new analysis by Fact.MR, the market is projected to increase from USD 32.5 billion in 2025 to USD 43.0 billion by 2035, advancing at a CAGR of 2.8%.

The report highlights nylon’s versatility across automotive, electronics, textile, industrial, and packaging applications, marking it as a cornerstone material for next-generation manufacturing.

Strategic Market Drivers

Automotive Lightweighting and Component Efficiency

The automotive sector remains a primary force behind nylon demand. Automakers continue to replace metal components with nylon-based engineered plastics to improve fuel efficiency, reduce emissions, and enhance thermal stability.

Nylon’s exceptional strength-to-weight ratio, fatigue resistance, and moldability make it ideal for under-the-hood parts, air-intake manifolds, battery housings, and EV-grade connectors.

Booming Electrical & Electronics Production

Nylon’s dielectric strength, flame resistance, and dimensional stability have made it a preferred material for electrical components, connectors, switches, housings, and circuit-protection systems.

The ongoing expansion in consumer electronics, telecom equipment, and EV charging infrastructure is fueling strong adoption.

Textiles and Industrial Applications Rebound

Nylon continues to be a core material in the textile and apparel sector due to its elasticity, abrasion resistance, and quick-dry properties.

Industrial yarns—used in tire cords, conveyor belts, fishing nets, and safety gear—are witnessing renewed demand driven by infrastructure renewal, mining, and logistics expansion across developing economies.

Rising Adoption in Packaging and 3D Printing

Nylon’s barrier properties and durability are driving its use in food packaging films, medical packaging, and high-performance pouches.

Its compatibility with additive manufacturing also supports growing usage in 3D printing for prototypes and functional components.

Browse Full Report: https://www.factmr.com/report/4598/nylon-market

Regional Growth Highlights

East Asia: The Global Nylon Manufacturing Hub

China, Japan, and South Korea collectively dominate the nylon landscape. The region benefits from integrated petrochemical capacities, rapid infrastructure growth, and strong demand from automotive and electronics manufacturers.

Continuous investments in nylon 6 and nylon 66 production technologies further reinforce East Asia’s leadership.

North America: Engineering Plastics and EV-Led Demand

The U.S. is seeing a surge in nylon consumption due to expanding electric vehicle production, aerospace innovation, and industrial automation.

Manufacturers are prioritizing high-performance nylon grades with improved thermal resistance, recyclability, and flame-retardant capabilities.

Europe: Regulation-Driven R&D and Circular Polymers

Europe’s sustainability policies and stringent material performance standards are prompting companies to develop bio-based nylon, recycled nylon (r-polyamides), and low-emission formulations.

Germany, France, and Italy remain major production and R&D hubs, particularly for automotive and industrial applications.

Emerging Markets: Infrastructure and Industrialization Boom

Latin America, South Asia, and the Middle East are experiencing notable growth, propelled by urbanization, textile exports, and the expansion of local manufacturing ecosystems.

Demand for industrial yarns, automotive components, and durable consumer goods is accelerating nylon penetration.

Market Segmentation Insights

By Product Type

- Nylon 6 – Preferred for fibers, packaging, and injection-molded components due to cost efficiency and versatility.

- Nylon 66 – Favored for high-strength engineering applications requiring heat resistance.

By Application

- Automotive & Transportation – Engineered components, housings, connectors.

- Textiles & Apparel – Filaments, industrial yarns, technical fabrics.

- Electrical & Electronics – Switchgear, connectors, insulation components.

- Industrial Machinery – Gears, bearings, fasteners, and mechanical parts.

- Packaging – Flexible films, multilayer structures, vacuum pouches.

- Consumer Goods – Sporting goods, power tools, appliances.

Challenges and Market Considerations

- Volatile Raw Material Prices: Fluctuations in petrochemical feedstock impact production costs and supply dynamics.

- Environmental Regulations: Strict sustainability requirements are compelling shifts toward recycled and bio-based nylon.

- Competition from Alternatives: Polyesters, PBT, and high-performance composites compete with nylon in some applications.

- Supply Chain Vulnerabilities: Geopolitical shifts and chemical feedstock constraints can disrupt nylon value chains.

Competitive Landscape

The nylon market is highly innovation-centric, with players focusing on advanced polymer chemistry, recycling technologies, and application-specific formulations.

Key Players in the Nylon Market

- BASF

- Invista

- Ascend Performance Materials

- AdvanSix

- Ube

- Toray

- DuPont

- DSM Engineering Materials

- Lanxess

- RadiciGroup

These companies are expanding global capacities, improving circular polymer solutions, and strengthening partnerships with automotive, electronics, and packaging manufacturers.

Recent Industry Developments

- Circular polymer initiatives are accelerating, with multiple players launching recycled nylon (rPA) lines for textiles, automotive components, and consumer goods.

- Bio-based nylon innovations are gaining momentum, reducing reliance on fossil feedstocks and improving environmental performance.

- Advanced compounding technologies are enabling nylon grades with higher heat resistance, improved strength, and superior chemical durability.

Future Outlook: Toward Sustainable, High-Performance Polyamides

The next decade will redefine nylon’s role in global manufacturing. Advancements in polymer engineering, closed-loop recycling, and bio-based materials will reshape value chains and reduce environmental impact.

With strong demand from automotive, electronics, industrial, and textile sectors, the nylon market is poised for consistent and resilient expansion.

Companies that focus on sustainability, advanced compounding, and strategic global partnerships will lead the next era of polymer innovation—delivering efficient, durable, and future-ready nylon solutions for an evolving world.