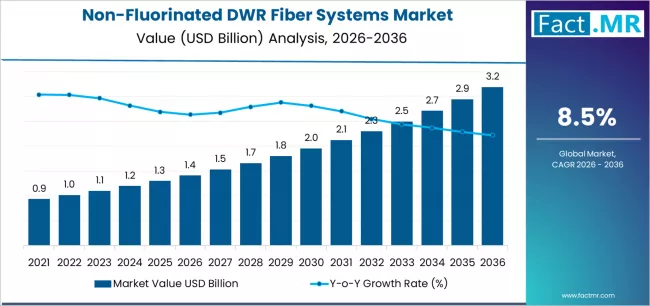

The global non-fluorinated DWR fiber systems market is set for strong and sustained expansion over the next decade, propelled by tightening environmental regulations, rising demand for sustainable textiles, and the global shift away from fluorocarbon-based chemical finishes. According to a new analysis by Fact.MR, the market is projected to grow from USD 1.41 billion in 2026 to USD 3.19 billion by 2036, registering a robust CAGR of 8.5% during the forecast period.

This growth represents a 126.2% total market expansion, underscoring the accelerating transition toward PFAS-free, eco-friendly water-repellent fiber technologies across apparel, home textiles, and industrial fabric applications.

The increasing emphasis on green chemistry, regulatory compliance, and consumer preference for sustainable products is significantly accelerating global adoption of non-fluorinated DWR fiber systems.

Browse Full Report: https://www.factmr.com/report/non-fluorinated-dwr-fiber-systems-market

Strategic Market Drivers

Sustainability Regulations Accelerate Market Adoption

Global regulatory bodies are actively restricting or banning fluorinated chemicals (PFAS) due to their environmental persistence and health risks. This regulatory shift is compelling textile manufacturers to adopt non-fluorinated DWR fiber systems that offer water repellency without ecological harm.

Regions including Europe, North America, and East Asia are leading compliance-driven transitions, fueling widespread market growth.

Rising Demand for Eco-Friendly Apparel and Textiles

Consumers are increasingly prioritizing sustainable, non-toxic, and environmentally responsible textiles, especially in:

- Outdoor & sportswear

- Performance apparel

- Home furnishings

Major apparel brands are integrating non-fluorinated DWR fiber systems into product lines to align with ESG goals and brand sustainability commitments.

Growth in Technical and Industrial Textiles

Non-fluorinated DWR solutions are gaining traction in industrial fabrics, including:

- Protective clothing

- Medical textiles

- Automotive interiors

- Military and defense fabrics

Their durability, safety profile, and regulatory compatibility make them ideal for high-performance applications.

Advancements in Bio-Based and Silicone DWR Technologies

Ongoing R&D in bio-based polymers, silicone emulsions, and wax-based chemistries is improving water repellency, wash durability, and fabric feel—narrowing the performance gap with traditional fluorinated finishes.

Regional Growth Highlights

Europe: Regulatory Leadership and Sustainability Focus

Europe remains a front-runner due to strict chemical regulations (REACH) and high adoption of sustainable textile manufacturing. Countries such as Germany, Italy, and France are leading innovation in PFAS-free fabric treatments.

North America: Strong Brand-Driven Adoption

Outdoor apparel and sportswear brands in the U.S. and Canada are rapidly transitioning to non-fluorinated DWR systems to meet consumer expectations and environmental compliance standards.

East Asia: Textile Manufacturing Hub

China, Japan, and South Korea are witnessing rising demand driven by:

- Large-scale textile production

- Export compliance requirements

- Innovation in sustainable fiber technologies

Emerging Markets: Expanding Textile and Apparel Industries

India, Southeast Asia, and Latin America are experiencing steady growth due to:

- Expanding garment manufacturing

- Rising sustainability awareness

- Increased export-oriented textile production

Market Segmentation Insights

By Chemistry Type

- Silicone-Based DWR Systems – Leading segment due to durability and flexibility

- Wax-Based Systems – Growing adoption in natural and organic textiles

- Bio-Based Polymers – High-growth segment driven by sustainability goals

By Application

- Apparel & Footwear – Largest segment driven by outdoor and performance wear

- Home Textiles – Curtains, upholstery, and bedding

- Industrial & Technical Textiles – Protective and specialty fabrics

- Medical Textiles – Infection-resistant and liquid-repellent materials

By End Use

- Sportswear & Outdoor Brands

- Fashion & Lifestyle Apparel

- Automotive & Transportation

- Healthcare & Defense

Challenges Impacting Market Growth

Performance Trade-Offs

Some non-fluorinated DWR systems may offer lower oil repellency compared to fluorinated alternatives, requiring continuous innovation to meet performance benchmarks.

Higher Processing Costs

Advanced sustainable chemistries and reformulation processes can increase production costs, especially for small and mid-scale manufacturers.

Durability Concerns

Ensuring long-lasting water repellency after repeated washing remains a key technical challenge for certain applications.

Competitive Landscape

The non-fluorinated DWR fiber systems market is moderately fragmented, with companies focusing on:

- Sustainable chemistry innovation

- Bio-based formulations

- Long-lasting wash durability

- Strategic partnerships with apparel brands

Key Companies Profiled

- Archroma

- Rudolf Group

- Huntsman Corporation

- Wacker Chemie AG

- Dow Inc.

- Pulcra Chemicals

- NICCA Chemical

- Tanatex Chemicals

Recent Developments

- 2024: Introduction of high-durability silicone-based PFAS-free DWR solutions for outdoor apparel

- 2023: Global apparel brands announce complete phase-out of fluorinated finishes

- 2022: Increased investment in bio-based water-repellent fiber technologies

Future Outlook: Sustainable Textile Innovation Through 2036

The next decade will witness transformative growth in the non-fluorinated DWR fiber systems market, driven by:

- Global PFAS bans and compliance mandates

- Rapid adoption of sustainable fashion

- Growth of technical and industrial textiles

- Innovation in bio-based and silicone chemistries

- Rising ESG commitments across textile value chains

As sustainability becomes a core pillar of textile manufacturing, non-fluorinated DWR fiber systems are positioned as the future standard for water-repellent fabrics, ensuring strong long-term market growth through 2036.