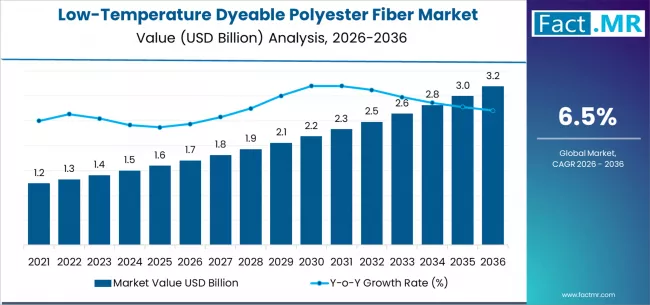

The global low-temperature dyeable polyester fiber market is set for steady and sustainable growth over the next decade, driven by rising demand for energy-efficient textile processing, reduced carbon emissions, and advanced fiber engineering. According to a new study by Fact.MR, the market is projected to expand from USD 1.70 billion in 2026 to USD 3.19 billion by 2036, reflecting an impressive 87.6% total growth and a compound annual growth rate (CAGR) of 6.5% during the forecast period.

Low-temperature dyeable polyester fibers enable dyeing at significantly lower temperatures compared to conventional polyester, resulting in lower energy consumption, reduced water usage, and improved fabric quality, making them increasingly attractive across the global textile and apparel industry.

Browse Full Report: https://www.factmr.com/report/low-temperature-dyeable-polyester-fiber-market

Strategic Market Drivers

Sustainability and Energy-Efficient Textile Processing

The textile industry is under growing pressure to reduce its environmental footprint. Low-temperature dyeable polyester fibers allow manufacturers to:

- Lower dyeing temperatures

- Reduce energy and water consumption

- Minimize CO₂ emissions

- Improve dye uptake and color uniformity

These benefits align closely with global sustainability initiatives and eco-friendly manufacturing standards.

Rising Demand for Functional and Performance Textiles

Increasing consumption of sportswear, athleisure, and technical textiles is accelerating adoption of advanced polyester fibers. Low-temperature dyeable variants offer:

- Enhanced softness and comfort

- Superior color fastness

- Improved processing efficiency

This makes them ideal for performance apparel, home textiles, and fashion garments.

Cost Optimization for Textile Manufacturers

By reducing dyeing temperatures and cycle times, manufacturers can significantly cut operational costs. This economic advantage is encouraging textile mills—especially in high-volume production hubs—to transition from conventional polyester fibers.

Technological Advancements in Fiber Engineering

Ongoing innovation in polymer modification and fiber structure design is improving the dye affinity of polyester fibers at lower temperatures. These advancements are expanding application scope while maintaining fabric strength, durability, and recyclability.

Regional Growth Highlights

East Asia: Global Textile Manufacturing Hub

China, Japan, and South Korea lead the market due to:

- Strong textile and apparel manufacturing base

- Rapid adoption of sustainable dyeing technologies

- Continuous innovation in synthetic fiber production

South Asia: Expanding Apparel and Export Industry

India, Bangladesh, and Sri Lanka are witnessing growing demand driven by:

- Expanding garment exports

- Increasing investments in energy-efficient textile processing

- Government initiatives promoting sustainable manufacturing

Europe: Sustainability Regulations Fuel Adoption

Strict environmental regulations and demand for eco-labeled textiles are accelerating adoption across Germany, Italy, France, and other EU nations.

North America: Innovation and Premium Textile Demand

Growth is supported by rising demand for high-performance fabrics, technical textiles, and sustainable fashion products.

Market Segmentation Insights

By Fiber Type

- Modified Polyester Fiber – Dominant due to improved dye affinity at lower temperatures

- Specialty Polyester Blends – Growing use in functional textiles

By Application

- Apparel & Fashion – Largest segment driven by sportswear and casual wear

- Home Textiles – Bedding, upholstery, and curtains

- Industrial & Technical Textiles – Automotive and functional fabric applications

By End Use

- Textile Mills – Primary consumers

- Garment Manufacturers – Increasing direct adoption

Challenges Impacting Market Growth

Higher Initial Material Costs

Low-temperature dyeable polyester fibers are more expensive than conventional polyester, which may slow adoption among small-scale manufacturers.

Limited Awareness in Developing Markets

Lack of technical knowledge and limited access to advanced dyeing infrastructure can restrain growth in emerging economies.

Competitive Landscape

The market is moderately competitive, with manufacturers focusing on:

- Sustainable fiber innovation

- Improved dyeability and fabric performance

- Strategic collaborations with textile mills

Key Companies Profiled

- Toray Industries

- Teijin Limited

- Indorama Ventures

- Reliance Industries Limited

- Far Eastern New Century

- Hyosung Corporation

Companies are investing in eco-friendly polymer modification, recyclable fibers, and low-impact dyeing solutions to strengthen market presence.

Future Outlook: Sustainable Fibers Shaping the Textile Industry

The next decade will see accelerated adoption of low-temperature dyeable polyester fibers, driven by:

- Global sustainability mandates

- Rising energy costs

- Demand for eco-conscious fashion

- Innovation in textile chemistry

As textile manufacturers prioritize energy efficiency, environmental compliance, and high-quality output, the global low-temperature dyeable polyester fiber market is positioned for strong and consistent growth through 2036.