The instrument reprocessing detergents market plays a critical role in modern healthcare by supporting effective infection prevention and patient safety. Medical instruments used in surgical procedures, diagnostics, and patient care are repeatedly exposed to biological contaminants such as blood, tissue, and microorganisms. Proper cleaning and reprocessing of these instruments are essential to prevent healthcare-associated infections and ensure compliance with stringent hygiene standards.

Instrument reprocessing detergents are specifically formulated to remove organic and inorganic residues from reusable medical devices before disinfection or sterilization. As healthcare facilities increasingly focus on quality assurance, regulatory compliance, and operational efficiency, demand for advanced and reliable reprocessing detergents continues to grow.

Market Overview

Instrument reprocessing detergents are specialized cleaning agents used during the pre-cleaning and automated washing stages of medical device reprocessing. These detergents are designed to be compatible with a wide range of materials, including stainless steel, plastics, and delicate instrument components.

The market is driven by the expansion of healthcare infrastructure, rising surgical volumes, and increasing emphasis on standardized reprocessing protocols. Hospitals, ambulatory surgical centers, and diagnostic laboratories are prioritizing detergents that ensure effective soil removal while maintaining instrument integrity.

In addition, the growing use of complex and minimally invasive surgical instruments has increased the need for detergents capable of penetrating narrow lumens and intricate device designs.

Key Market Drivers

Rising Focus on Infection Prevention

Healthcare-associated infections remain a major concern for healthcare providers worldwide. Instrument reprocessing detergents form the first and most critical step in eliminating contamination, making them essential to effective infection control programs.

Increasing Surgical and Diagnostic Procedures

The growing number of surgical interventions and diagnostic procedures has led to higher utilization of reusable medical instruments. This trend directly increases demand for high-performance reprocessing detergents.

Strict Regulatory and Accreditation Standards

Healthcare facilities must comply with stringent guidelines issued by regulatory authorities and accreditation bodies. These standards emphasize validated cleaning processes, driving the adoption of specialized detergents designed for medical instrument reprocessing.

Growth of Central Sterile Services Departments

The expansion of centralized sterilization departments in hospitals has increased the use of automated washer-disinfectors, which require detergents optimized for machine-based cleaning cycles.

Detergent Type Insights

Enzymatic Detergents

Enzymatic detergents are widely used due to their ability to break down organic matter such as proteins, fats, and carbohydrates. These detergents are particularly effective for cleaning surgical instruments with complex geometries.

Neutral pH Detergents

Neutral detergents are valued for their material compatibility and low corrosiveness. They are commonly used for delicate instruments and devices sensitive to harsh chemicals.

Alkaline Detergents

Alkaline detergents provide strong cleaning performance for heavy soil loads. They are often used in automated reprocessing systems where robust cleaning is required.

Low-Foaming Detergents

Low-foaming formulations are essential for automated washer-disinfectors, ensuring effective circulation and rinsing without disrupting machine performance.

Application Outlook

Surgical Instrument Cleaning

Surgical instruments represent the largest application segment, requiring thorough removal of biological residues prior to sterilization. Reprocessing detergents ensure consistent and repeatable cleaning outcomes.

Endoscope Reprocessing

Flexible and rigid endoscopes require specialized detergents capable of cleaning narrow channels and sensitive components without causing damage.

Dental Instrument Reprocessing

Dental clinics rely on instrument reprocessing detergents to maintain hygiene standards and prevent cross-contamination between patients.

Laboratory and Diagnostic Equipment

Laboratory instruments and diagnostic devices also require effective cleaning solutions to maintain accuracy and safety in clinical testing environments.

End-Use Industry Analysis

Hospitals

Hospitals are the primary end users due to high instrument volumes and strict compliance requirements. Central sterile departments depend on reliable detergents to support daily operations.

Ambulatory Surgical Centers

Ambulatory surgical centers require efficient and standardized reprocessing solutions to manage high procedure turnover while maintaining patient safety.

Diagnostic Laboratories

Diagnostic and pathology laboratories use detergents to clean reusable tools and equipment, ensuring contamination-free testing processes.

Dental and Specialty Clinics

Smaller healthcare facilities rely on easy-to-use and effective detergents that support both manual and automated cleaning processes.

Regional Insights

North America

North America remains a key market due to advanced healthcare infrastructure and strong emphasis on infection control and regulatory compliance.

Europe

Europe demonstrates steady demand driven by standardized healthcare practices and strict medical device reprocessing guidelines.

Asia-Pacific

Rapid healthcare expansion, increasing surgical volumes, and improving infection control awareness are driving market growth in the Asia-Pacific region.

Latin America and Middle East & Africa

These regions are witnessing gradual adoption supported by healthcare infrastructure development and increasing focus on patient safety standards.

Technological Advancements

Innovation in detergent formulations is improving cleaning efficiency while enhancing material compatibility and environmental safety. Manufacturers are developing detergents with enhanced enzyme blends, improved soil removal capabilities, and reduced residue formation.

Advancements in automated reprocessing equipment are also influencing detergent design, with formulations tailored to specific washer-disinfector cycles. Eco-friendly and low-toxicity detergents are gaining traction as healthcare facilities prioritize sustainability and worker safety.

Competitive Landscape

The instrument reprocessing detergents market features global healthcare solution providers, specialty chemical manufacturers, and regional suppliers. Competition is based on product performance, compatibility with medical devices, regulatory compliance, and technical support.

Companies are focusing on expanding their product portfolios and offering detergents optimized for different instrument types and reprocessing methods. Strategic collaborations with healthcare facilities and equipment manufacturers are common to ensure integrated solutions.

Challenges and Market Constraints

Despite strong demand, the market faces challenges such as rising complexity of medical instruments and the need for continuous staff training on proper reprocessing protocols. Inadequate cleaning due to improper detergent selection or usage can compromise patient safety.

Additionally, balancing cleaning efficacy with material compatibility and environmental considerations requires ongoing innovation and validation.

Future Outlook

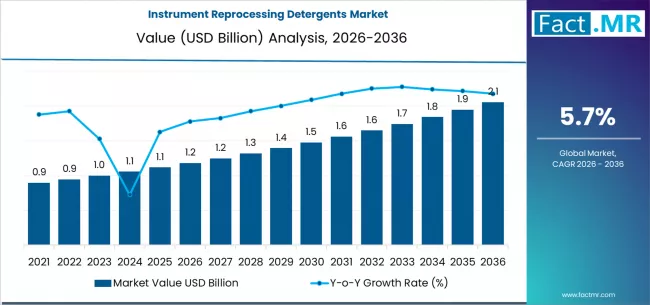

The instrument reprocessing detergents market is expected to continue evolving as healthcare systems prioritize infection prevention and operational efficiency. Growing adoption of minimally invasive procedures and reusable medical devices will sustain demand for advanced detergent solutions.

Opportunities exist in emerging markets, hospital infrastructure upgrades, and the development of sustainable and enzyme-based formulations. Manufacturers that emphasize quality, compliance, and innovation are likely to gain a competitive edge.

Conclusion

Instrument reprocessing detergents are a cornerstone of safe and effective healthcare delivery, ensuring that reusable medical devices are thoroughly cleaned and ready for sterilization. As healthcare standards continue to advance, the importance of reliable and high-performance reprocessing detergents will only increase.

Access to comprehensive market insights and industry analysis can help healthcare providers, manufacturers, and stakeholders make informed decisions and implement best practices. By investing in effective instrument reprocessing solutions, the healthcare sector can strengthen patient safety, regulatory compliance, and overall quality of care.

Browse Full Report – https://www.factmr.com/report/instrument-reprocessing-detergents-market