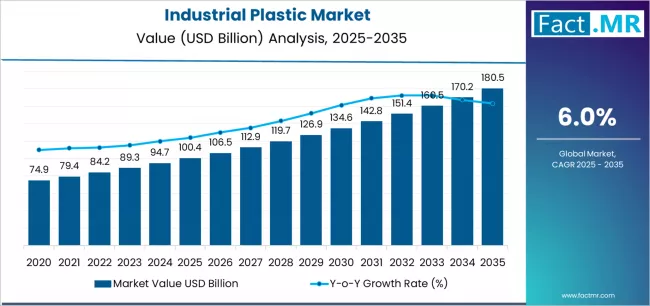

The global industrial plastic market is on track for substantial expansion, driven by accelerating industrialization, technological advancements in polymer engineering, and rising demand for lightweight, high-performance materials across key end-use sectors. According to the latest analysis, the market is projected to grow from USD 100.4 billion in 2025 to USD 180.5 billion by 2035, reflecting an absolute increase of USD 80.1 billion and registering a CAGR of 6.0% over the forecast period.

Industrial plastics—including engineered thermoplastics, commodity plastics, and high-performance polymers—are increasingly replacing metals due to their excellent chemical resistance, durability, processing versatility, and cost efficiency. These materials are becoming essential components in automotive, electronics, construction, medical, and packaging applications.

Key Market Drivers

Lightweighting Trend Across Automotive & Transportation

Automakers are rapidly adopting industrial plastics to reduce vehicle weight, improve fuel efficiency, and meet stringent environmental regulations. Advanced engineering plastics such as polycarbonate, ABS, and nylon are being used in interior, exterior, and under-the-hood applications. The rise of electric vehicles (EVs) further boosts demand for high-performance polymers used in battery casings, wiring insulation, and structural components.

Boom in Electronics & Electrical Manufacturing

The expanding consumer electronics sector is fueling the need for highly durable, heat-resistant, and electrically insulating plastics. Materials such as polyamide, polybutylene terephthalate (PBT), and polyphenylene sulfide (PPS) are increasingly used in connectors, switches, housings, and circuit components to ensure safety and performance.

Rising Construction Activities in Emerging Markets

Industrial plastics play a critical role in modern construction—used in piping, insulation, window frames, and structural reinforcements. Their corrosion resistance, moisture tolerance, and long lifespan make them ideal for infrastructure projects, especially in rapidly urbanizing regions across Asia-Pacific and the Middle East.

Browse Full Reports: https://www.factmr.com/report/industrial-plastic-market

Growing Focus on High-Performance Materials

Industries are shifting toward plastics capable of withstanding harsh environments, extreme temperatures, and mechanical stress. High-performance polymers, including PEEK and fluoropolymers, are gaining traction in aerospace, energy, and medical device manufacturing.

Regional Growth Highlights

North America: Innovation Hub for High-Performance Plastics

The region leads in advanced polymer development, driven by strong automotive, aerospace, and electronics industries. Adoption of sustainable and recycled plastic solutions is accelerating market growth.

Europe: Strong Sustainability & Recycling Framework

With strict environmental policies, Europe continues to push for recyclable and bio-based industrial plastics. Demand is strong in automotive, packaging, and construction.

Asia-Pacific: Fastest-Growing Market

China, India, Japan, and Southeast Asian countries are witnessing rapid industrial expansion. Mass manufacturing, electronics output, and construction growth position APAC as a key market accelerator.

Middle East & Africa: Industrial Diversification Supports Growth

Investment in petrochemicals, infrastructure development, and manufacturing facilities supports steady market expansion.

Market Segmentation Insights

By Polymer Type

- Engineering Plastics – High growth due to applications in automotive, electronics, and industrial machinery.

- Commodity Plastics – Widely used in packaging, consumer goods, and construction.

- High-Performance Plastics – Rising adoption in aerospace, medical devices, and energy sectors.

By End Use

- Automotive & Transportation

- Electronics & Electrical

- Construction & Infrastructure

- Industrial Machinery

- Packaging

- Healthcare & Medical Devices

Market Challenges

Despite strong growth prospects, the industrial plastic market faces several limitations:

- Environmental Concerns: Increasing pressure to minimize plastic waste and improve recyclability.

- Fluctuating Raw Material Prices: Petrochemical-derived plastic prices remain volatile.

- Regulatory Restrictions: Stricter rules on plastic production and usage in many regions.

- Competition from Bio-Based Alternatives: Growing demand for sustainable materials challenges conventional plastics.

Competitive Landscape

The industrial plastic market is moderately fragmented, with global players investing in capacity expansion, advanced material development, and sustainability initiatives. Key companies are focusing on circular economy strategies, recycling technologies, and high-performance polymer innovations.

Prominent Companies Include:

- BASF SE

- SABIC

- Dow Inc.

- LyondellBasell

- DuPont

- Covestro

- Celanese Corporation

- Mitsubishi Chemical Group

These companies are expanding manufacturing capabilities, strengthening R&D investments, and forming strategic partnerships to meet rising global demand.

Future Outlook: Toward Sustainable, High-Performance Industrial Materials

Over the next decade, industrial plastics will play an essential role in transforming manufacturing, mobility, infrastructure, and technology. As industries prioritize lightweighting, durability, and cost efficiency, demand for engineered and high-performance plastics will continue to rise.

Manufacturers that adopt sustainable production practices, invest in recycling technologies, and develop specialized polymer solutions are poised to lead the next phase of global industrial plastic market expansion.