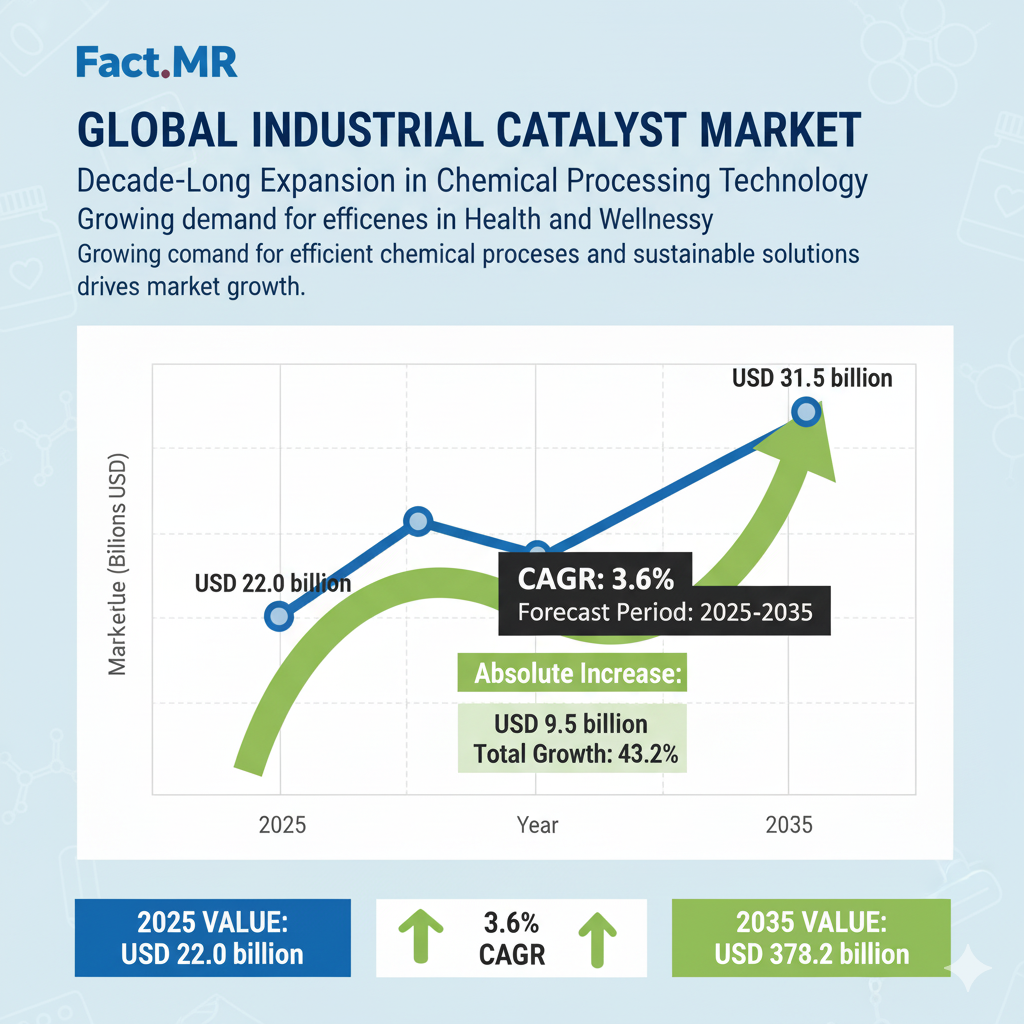

The industrial catalyst market stands at the threshold of a decade-long expansion trajectory that promises to reshape chemical processing technology and industrial reaction solutions. The market’s journey from USD 22.0 billion in 2025 to USD 31.5 billion by 2035 represents substantial growth, The market will rise at a CAGR of 3.6% This growth signals a robust expansion in chemical processing technologies, refining modernization, and process optimization initiatives that are reshaping the way industrial reactions are managed across multiple sectors.

A Market Redefining Industrial Chemistry:

The industrial catalyst sector is the cornerstone of modern chemical processing, enabling higher reaction efficiency, lower energy consumption, and reduced environmental footprint. Over the next ten years, the industry will transition from traditional catalyst formulations to digitally monitored, performance-optimized catalyst systems that align with sustainability and operational excellence targets.

From USD 22.0 billion in 2025, the market is expected to grow steadily, adding USD 9.5 billion in value by 2035, driven by rapid advancements in heterogeneous catalyst systems, automated reaction control, and digital process integration. These innovations are revolutionizing operations across refining, petrochemical, chemical, and environmental applications.

Two-Phase Growth Outlook:

2025–2030: The market will rise from USD 22.0 billion to USD 26.2 billion, contributing 45% of the total decade growth. This period marks the accelerated adoption of heterogeneous catalysts across refining and petrochemical sectors, where automation and precision control become operational standards.

2030–2035: The second half of the decade will add USD 5.3 billion, as specialized catalyst technologies achieve mass-market penetration. Integration with process management platforms and predictive analytics will redefine catalyst performance monitoring, ushering in an era of intelligent reaction systems.

Heterogeneous Catalysts Drive Market Dominance:

The heterogeneous catalyst segment accounts for 70% of total market revenue, solidifying its position as the industry’s performance backbone. Their advantages—selectivity, stability, and operational efficiency—make them indispensable in large-scale refining and petrochemical applications.

Manufacturers are investing heavily in automated selectivity control systems, predictive maintenance tools, and data-driven process management, transforming catalysts into integral components of smart industrial ecosystems.

Meanwhile, homogeneous catalysts (20% share) are gaining traction in specialty chemical synthesis, while enzymatic catalysts (10% share) are expanding through green chemistry and biotechnology initiatives.

Refining Segment Leads in Application Growth:

Refining remains the largest application segment, representing 35% of global demand, supported by worldwide refinery modernization and energy transition goals. The need for cleaner fuels and efficient conversion processes ensures steady catalyst deployment across all refining operations.

The petrochemical sector follows closely with 30% market share, driven by surging polymer and specialty chemical production. The chemical manufacturing segment (20%) and environmental applications (10%) also show healthy growth trajectories, supported by stricter emission control and waste treatment mandates.

Material Innovation: Metals and Zeolites Lead the Way:

– Metal-based catalysts (40%) dominate due to their unmatched performance and durability in high-temperature industrial applications.

– Zeolites (30%) are gaining share for their shape-selective properties and energy-efficient processing features.

– Oxides (20%) maintain their foothold in thermal stability applications, while composite materials (10%) signal emerging innovation opportunities.

Regional Growth Hotspots:

Asia Pacific emerges as the growth epicenter of the industrial catalyst market, led by India (5.0% CAGR) and China (4.2% CAGR). India’s aggressive industrialization and chemical modernization programs are setting new standards for catalyst technology integration. In China, the ongoing chemical expansion in Shandong, Jiangsu, and Liaoning is fueling large-scale deployment of advanced catalysts.

Europe remains a hub of technological leadership, with Germany (3.3%), the UK (3.1%), and France (2.9%) focusing on sustainable catalyst innovation and regulatory compliance.

In North America, the United States (3.2%) continues to lead through advanced application development, leveraging established refining and petrochemical infrastructure for large-scale catalyst implementation.

Competitive Landscape: Technology at the Core:

The industrial catalyst market is moderately consolidated, with 12–15 key global players controlling 35–40% of total revenue. Market leaders such as BASF, Johnson Matthey, Clariant, W.R. Grace, and Albemarle maintain dominance through:

– Technology Innovation Focused R&D in selectivity, regeneration, and process integration.

– Performance Reliability Proven track records in large-scale refining and petrochemical operations.

– Application Versatility Expanding offerings across chemicals, energy, and environmental sectors.

Emerging opportunities lie in custom catalyst development, digital monitoring integration, and performance-based pricing models, where service and analytics become integral to customer value.

Future Outlook: Toward Smart, Sustainable Catalysis:

The next decade will mark a paradigm shift from static catalyst systems to adaptive, intelligent catalyst ecosystems. Industrial facilities will increasingly adopt data-centric catalyst management, AI-driven process analytics, and modular catalyst systems that enable real-time optimization and sustainability tracking.

Companies that invest in performance-linked catalyst models, digital integration, and regional customization will not only capture market share but also define the next generation of industrial catalysis.

With its growth poised to surpass USD 31.5 billion by 2035, the industrial catalyst market stands as a pivotal enabler of global industrial transformation—fueling cleaner, smarter, and more efficient chemical processing across industries.

Browse Full Report-https://www.factmr.com/report/industrial-catalyst-market