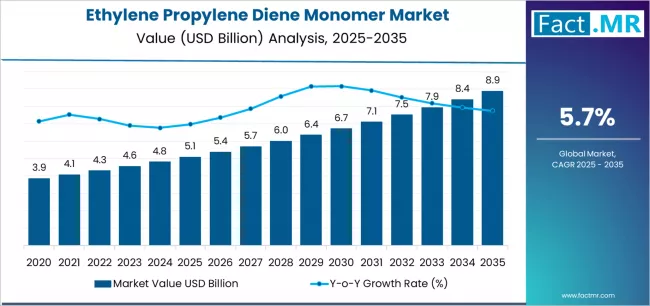

The market for ethylene propylene diene monomer is expected to grow by USD 3.78 billion over the forecast period, reaching USD 8.88 billion by 2035. The market is expected to grow at a compound annual growth rate (CAGR) of 5.7% during the assessment period, with a projected value of USD 5.10 billion in 2025.

Ethylene Propylene Diene Monomer (EPDM) rubber is positioned for steady growth over the next decade. Valued for excellent resistance to weathering, ozone, heat, and aging, plus strong sealing and electrical insulation properties, EPDM is widely used across automotive, construction, electrical, and industrial applications. Trends such as electric vehicle adoption, sustainable building practices, expanding renewable-energy infrastructure, and demand for durable insulation and sealing materials are all supporting robust EPDM consumption globally.

Quick Stats (2025–2035)

-

Market Value 2025 (global): USD 4.90 billion

-

Forecast Market Value 2035 (global): USD 8.10 billion

-

Absolute Growth (2025–2035): USD 3.20 billion

-

Forecast CAGR (2025–2035): ≈ 5.2%

-

Primary Application (2025): Automotive sealing & hoses (≈ 50% share)

-

Fastest-Growing Application: EPDM for EV battery & high-voltage insulation

To access the complete data tables and in-depth insights, request a Discount On The Report here: https://www.factmr.com/connectus/sample?flag=S&rep_id=4947

Key Market Drivers

1. Automotive Industry & EV Transition

-

EPDM is the material of choice for weather-strips, door seals, hoses, grommets and under-hood components because of thermal and ozone resistance.

-

Electrification of vehicles drives new uses — high-voltage cable jacketing, battery enclosure seals, and thermal-management components — lifting demand for specialized EPDM grades.

-

Lightweighting and long-term durability targets increase replacement of heavier materials with elastomers like EPDM.

2. Construction, Roofing & Building Materials

-

EPDM roofing membranes, waterproofing seals, and facade gaskets benefit from long service life, UV stability, and minimal maintenance.

-

Urbanization and retrofit activity for energy-efficient buildings support rising EPDM uptake in commercial and residential construction.

3. Renewable Energy & Electrical Insulation

-

EPDM is increasingly used in cable jacketing, connector seals and insulation for solar and wind installations as renewable deployments expand.

-

Its dielectric properties and weather resistance make EPDM suitable for outdoor electrical applications and cable protection.

4. Industrial & Specialty Applications

-

Hoses, gaskets, belts, and industrial sealing solutions in manufacturing and utilities depend on EPDM for chemical and heat resistance.

-

Customized polymerization and compounding allow producers to create grades tailored for specific industrial demands.

Market Structure & Segment Insights

By Application

-

Automotive (largest): Seals, hoses, window channels, and interior components account for the lion’s share.

-

Building & Construction: Roofing membranes, seals, and waterproofing systems represent a major, stable market.

-

Electrical & Insulation: Cable jacketing, high-voltage harnesses, and renewable-energy components are growing rapidly.

-

Industrial & Others: Hoses, gaskets, molded parts, and specialty compounds serve diverse manufacturing needs.

By Production Process & Grade

-

Solution-Polymerized EPDM: Dominant for high-performance applications because of flexibility in tailoring molecular weight and diene content.

-

Suspension/Other Grades: Cost-effective variants used in commodity sealing and basic construction applications.

-

Specialty Compounds: Flame-retardant, heat-stable, and high-dielectric grades command premium pricing.

By Region

-

Asia-Pacific: Leading regional demand due to automotive manufacturing, construction, and industrialization.

-

Europe & North America: Strong markets driven by EV adoption, building renovation, and renewable infrastructure.

-

Rest of World: Growing pockets of demand tied to infrastructure projects and industrialization.

Challenges & Restraints

-

Feedstock Price Volatility: EPDM relies on ethylene and propylene feedstocks; petrochemical volatility can impact margins.

-

Competition from Alternative Materials: Thermoplastic elastomers, silicones, and other rubbers offer competing properties—especially where recyclability or specific performance is prioritized.

-

Sustainability Pressure: As regulators and customers push for lower carbon footprints, EPDM makers face pressure to develop recycled-content or bio-based solutions.

-

High Customization Costs: Automotive and high-end applications require tight specifications and quality control, raising R&D and production costs.

Opportunities & Strategic Directions

-

EV & High-Voltage Insulation Grades: Develop EPDM compounds optimized for battery seals, HV cable jacketing, and thermal stability to capture EV-related growth.

-

Green Building & Durable Roofing: Market EPDM as a long-life, low-maintenance roofing and sealing solution for energy-efficient buildings and retrofit projects.

-

Renewable-Energy Infrastructure: Target solar and wind sectors with UV-stable, long-durability compounds for outdoor cable and sealing applications.

-

Recycled & Low-Carbon EPDM: Invest in post-industrial recycling, chemically recycled feedstocks, or bio-based monomers to meet sustainability mandates and brand demands.

-

Value-Added Compounds & Technical Support: Offer specialty compounding, certification, and application engineering support to OEMs and construction firms.

Outlook

EPDM demand is expected to grow from roughly USD 4.9 billion in 2025 to about USD 8.1 billion by 2035, at an approximate 5.2% CAGR. Growth will be anchored in automotive sealing and hoses, with the fastest expansion in EV-related insulation, renewable-energy applications, and durable building materials. Suppliers that combine robust feedstock management, product innovation (including eco-friendly grades), and close OEM or contractor partnerships will capture the principal share of market gains. Overall, EPDM’s combination of weather resistance, thermal stability, and electrical properties ensures it remains a core elastomer for infrastructure, mobility, and industrial needs over the next decade.

Browse Full Report: https://www.factmr.com/report/4947/epdm-market