The environmentally safe release agents for molding and casting market is poised for sustained growth over the next decade as industries increasingly adopt eco-friendly manufacturing practices and stringent environmental regulations drive the transition away from solvent-based and hazardous release formulations. Environmentally safe release agents are specialized chemicals used to ensure clean separation of molded or cast parts from tooling surfaces without damaging the mold or the finished component. With performance characteristics comparable to traditional agents but with significantly reduced environmental and health impacts, these solutions are gaining traction across automotive, aerospace, construction, consumer goods, and industrial manufacturing sectors.

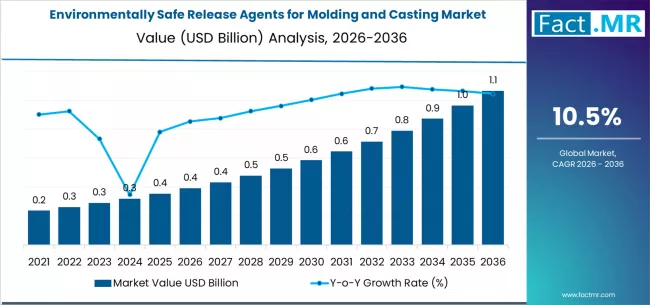

In 2026, the global market for environmentally safe release agents for molding and casting applications is estimated at USD 1.04 billion. By 2036, the market is expected to reach approximately USD 2.23 billion, reflecting a stable compound annual growth rate (CAGR) of about 7.2% over the forecast period. The growth trajectory reflects the increasing integration of sustainable materials in manufacturing processes and rising demand for products that meet both performance and environmental standards.

To access the complete data tables and in-depth insights, request a Discount On The Report here: https://www.factmr.com/connectus/sample?flag=S&rep_id=13004

Market Overview

Release agents are critical components in molding and casting operations. They facilitate the removal of parts from molds, dies, and casting surfaces by forming a thin barrier that prevents adhesion. Historically, many release agents relied on solvent-based chemistries or components that posed environmental and occupational risks due to high volatile organic compound (VOC) content or the presence of hazardous substances.

Environmentally safe release agents are formulated to address these concerns through the use of water-based carriers, biodegradable oils, plant-derived lubricants, and low-toxicity polymers. These formulations help reduce VOC emissions, improve workplace safety, and support compliance with evolving environmental regulations, without compromising on key performance metrics such as mold protection, surface finish quality, and ease of application.

Key Market Drivers

1. Regulatory and Environmental Compliance

Regulatory frameworks worldwide are tightening standards on chemical emissions, waste handling, and worker safety in industrial environments. Environmental protection agencies and occupational safety authorities are placing greater emphasis on reducing VOC emissions and exposure to hazardous chemicals. As a result, manufacturers are progressively replacing conventional solvent-based release agents with environmentally safe alternatives that align with regulatory expectations and sustainability goals.

2. Consumer and Brand Sustainability Expectations

Consumers are increasingly conscious of the environmental footprint of products and manufacturing practices. Brand owners and original equipment manufacturers (OEMs) are responding by integrating sustainable materials into their supply chains. Using environmentally safe release agents not only helps companies demonstrate responsible production practices but also reduces the environmental impact of finished goods, enhancing corporate reputation and market appeal.

3. Growth in Key End-Use Industries

Industries such as automotive and aerospace are major users of molding and casting technologies. With rising demand for lightweight composite components, precision-cast parts, and complex molded structures, the need for effective release agents has expanded. At the same time, these industries are under pressure to meet stringent environmental and safety standards, increasing the adoption of eco-friendly release formulations.

4. Workplace Health and Safety Considerations

Health and safety concerns associated with traditional release agents, particularly those that volatilize harmful substances during application, have prompted manufacturers to seek safer alternatives. Environmentally safe release agents support reduced exposure to harmful emissions, lower risk of respiratory irritation for workers, and compliance with occupational health protocols.

Market Segmentation Insights

By Product Type

-

Water-Based Release Agents: Offer minimal VOC emissions and broad compatibility with various molding and casting processes.

-

Biodegradable Oil-Based Agents: Provide effective lubrication and release performance while supporting reduced environmental persistence.

-

Polymer and Silicone-Free Formulations: Designed for applications requiring specific surface compatibility or regulatory compliance.

-

Specialty and Hybrid Agents: Customized for high-performance applications, including composites and precision casting.

By End-Use Industry

-

Automotive: A key sector with widespread use of molded components and composites for lightweighting and performance.

-

Aerospace: Requires high-precision release solutions that meet rigorous safety and environmental requirements.

-

Construction and Infrastructure: Uses molded parts such as architectural elements and engineered components.

-

Consumer Appliances and Goods: Includes molded plastics and cast products with strict surface quality needs.

-

Industrial Machinery and Equipment: Uses release agents for robust metal and polymer parts in heavy-duty applications.

Regional Market Dynamics

North America

North America represents a significant share of the market due to advanced industrialization, stringent environmental regulation, and strong adoption of sustainable manufacturing practices. Automotive and aerospace sectors in the United States and Canada are leading users of environmentally safe release agents.

Europe

Europe is a key market supported by comprehensive environmental policies, strict emission standards, and strong sustainability frameworks that influence material selection and production processes. Manufacturers across Germany, France, Italy, and other European countries are integrating eco-friendly release solutions to meet regulatory compliance and consumer expectations.

Asia Pacific

Asia Pacific is expected to witness rapid growth due to expanding manufacturing capacity in economies such as China, India, Japan, and Southeast Asian countries. Rising industrial activity, increasing automotive production, and growing emphasis on environmental safety are driving adoption of environmentally safe release agents.

Latin America and Other Regions

Latin America and other emerging regions are gradually increasing uptake as industrialization expands and environmental policies evolve. Adoption in these regions is supported by growing awareness of sustainability and the expansion of formal manufacturing sectors.

Competitive Landscape

The environmentally safe release agents for molding and casting market is moderately competitive, with participation from major chemical manufacturers, specialty industrial coatings suppliers, and regional formulators focused on eco-friendly solutions. Key players are focusing on product innovation, expansion of sustainable product portfolios, and partnerships to ensure compatibility with diverse molding and casting processes.

Strategic initiatives include development of low-VOC and biodegradable formulations, enhanced technical support services for process integration, and expanded distribution networks to reach global manufacturing hubs. Product differentiation is often based on performance attributes such as release efficiency, environmental compliance, compatibility with different mold materials, and ease of application.

Future Outlook

The environmentally safe release agents for molding and casting market is expected to sustain solid growth through 2036 as manufacturers worldwide prioritize sustainability, regulatory compliance, and workplace safety. Continued advances in biodegradable chemistries, water-based technologies, and eco-certified materials will support broader market adoption.

As industries face increasing regulatory and consumer pressure to reduce environmental impacts, environmentally safe release agents will play a critical role in enabling responsible manufacturing practices. Their integration into molding and casting operations will help organizations achieve performance goals while demonstrating environmental stewardship — a key competitive differentiator in the evolving industrial landscape.

Browse Full Report: https://www.factmr.com/report/environmentally-safe-release-agents-for-molding-and-casting-market